Environment-friendly PI film production process

A production process and environment-friendly technology, which is applied in the field of PI film preparation, can solve the problems of PI film preparation technology blockade, preparation process is not green enough, low preparation technology efficiency, etc., to achieve reliability assurance, waste water reduction, and process optimization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

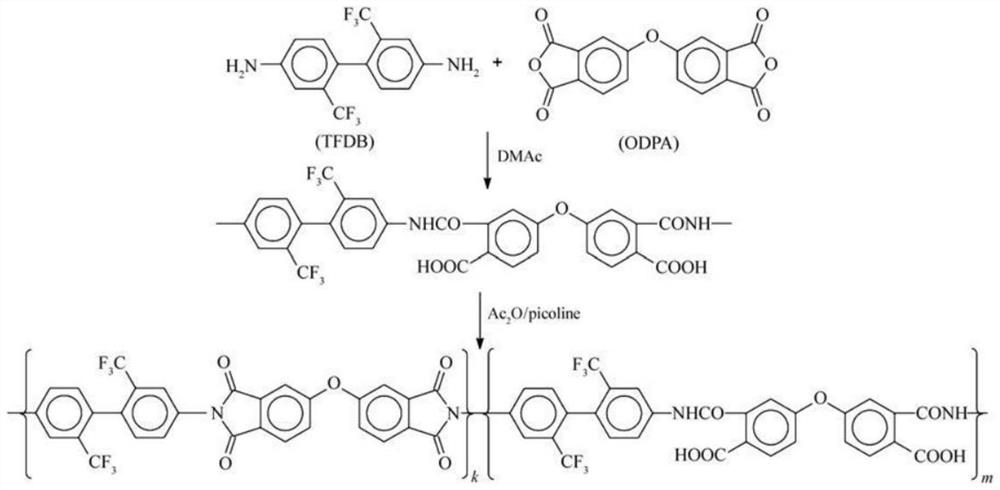

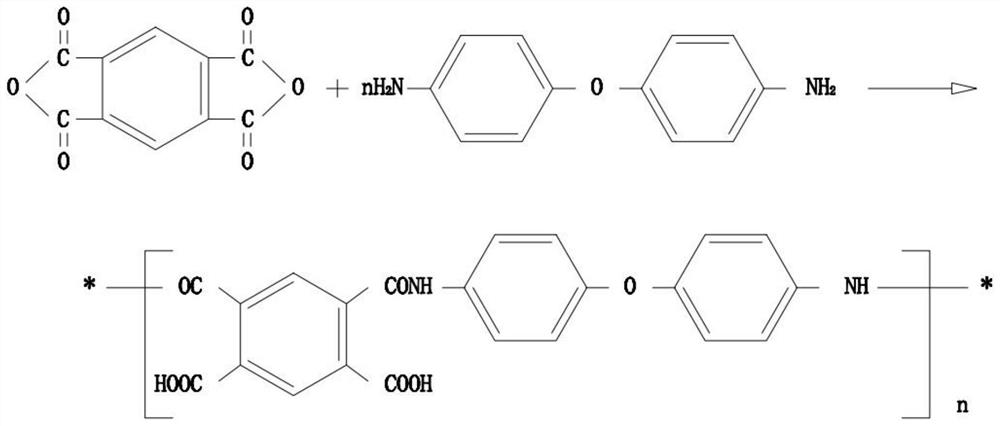

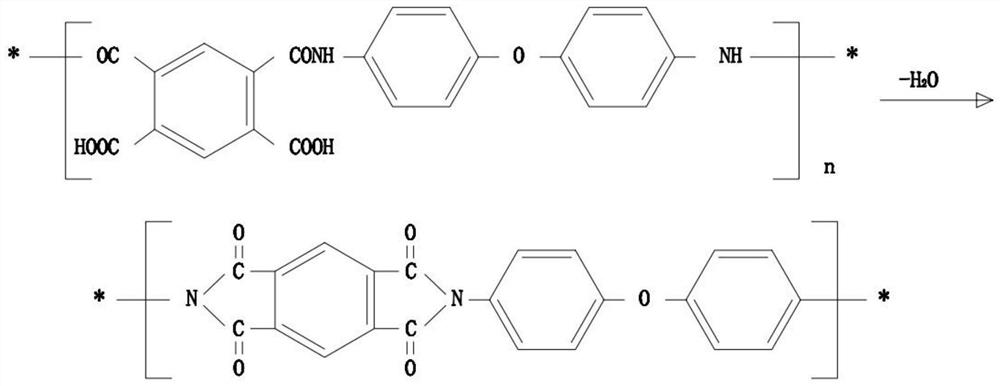

[0039] see Figure 1-4 , the present invention provides a kind of technical scheme: a kind of PI film environment-friendly production process, the specific steps of this PI film environment-friendly production process are as follows:

[0040] S1: The reaction condensation is carried out with the catalyst of base A plus dihydrogen chloride and eight liters of ammonia B. Under the continuous catalytic reaction at high temperature, the condensation reaction becomes phthalimide. Under the DAXNER reactor, the uninterrupted continuous reaction ;

[0041] The continuity is carried out by the stable temperature-controlled and pressure-controlled reactor of the DAXNER reactor, and the continuous automatic quantitative addition of phthalic anhydride is completed by the automatic supply system of the DAXNER reactor; the entire process flow is automatically controlled and executed by the DAXNER reactor, continuous, On-line, continuous automatic feeding, automatic temperature adjustment, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com