A kind of emulsification regeneration agent with workability and preparation method thereof

A technology for emulsifying regenerant and emulsifier, applied in building components, building insulation materials, buildings, etc., can solve the problems of high heating temperature, poor construction workability, etc., to improve the interface state, improve construction workability, and ensure long-term The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of emulsification regeneration agent A, step is as follows:

[0024] (1) Heat 55.8 parts by mass of the minus four-line extracted oil to 130°C, add 2.4 parts by mass of SBS modifier, and cut with a shear for 60 min. Then at 80°C, add 1.2 parts by mass of silane coupling agent KH 550, and after ultrasonic dispersion for 60 minutes, add 1.2 parts of sulfur powder and stir for 120 minutes at 120°C to prepare component A.

[0025] (2) Heat 39.2 parts by mass of water to 50°C, add 0.4 parts by mass of slow-cracking and fast-setting cationic emulsifier PRAC417 and 0.4 parts by mass of dilute hydrochloric acid with a mass fraction of 20%, stir until the flocs disappear, and adjust the pH to 2 , formulated as emulsion B.

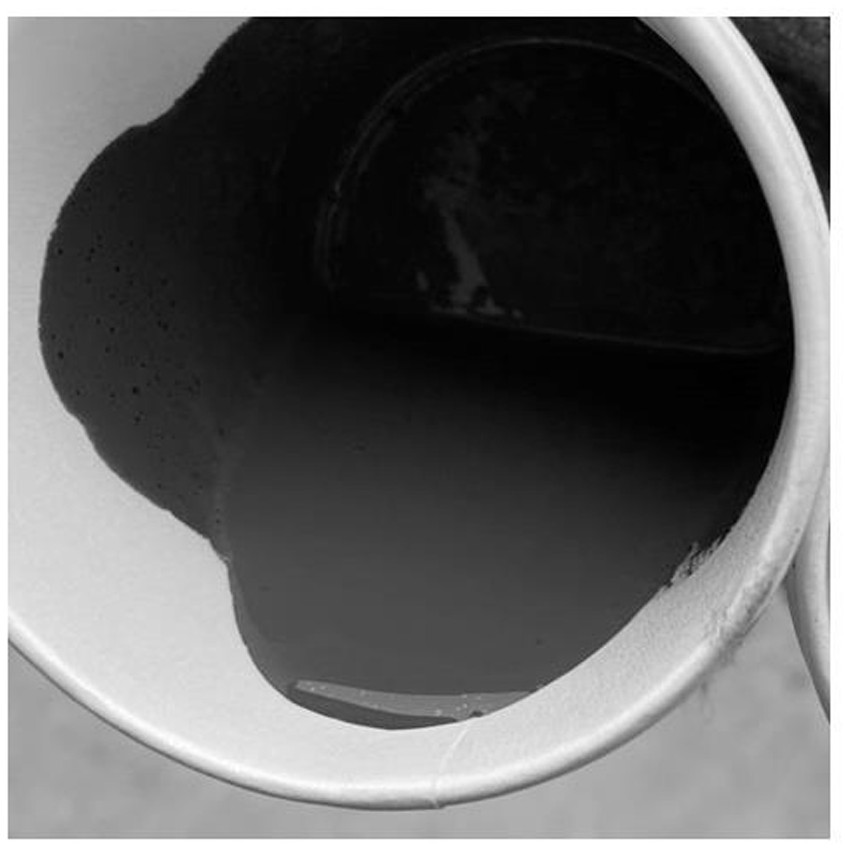

[0026] (3) Heat component A to 100°C, then add emulsion B, and emulsify and shear at 3500 rpm for 45 min at 80°C to prepare emulsified regenerant, such as figure 1 shown.

Embodiment 2

[0028] The preparation of emulsification regeneration agent B, the steps are as follows:

[0029] (1) Heat 48.3 parts by mass of minus three-line extracted oil to 110°C, add 0.9 parts by mass of SBR modifier, and cut it with a shear for 75 min. Then at 90°C, add 0.6 parts by mass of chelating titanate coupling agent QX-311W, ultrasonically disperse for 45 minutes, then add 0.2 parts of polyisobutylene and stir for 140 minutes at 110°C to prepare Component A.

[0030] (2) Heat 49.5 parts by mass of water to 60°C, add 0.3 parts by mass of slow-cracking and fast-setting cationic emulsifier MQ65 and 0.2 parts by mass of dilute hydrochloric acid with a mass fraction of 20%, stir until the flocs disappear, and adjust the pH to 2.2 , formulated as emulsion B.

[0031] (3) Heat component A to 90°C, then add emulsion B, and emulsify and shear at 3000 rpm for 60 minutes at 70°C to prepare emulsified regenerant B.

Embodiment 3

[0033] The preparation of emulsification regeneration agent C, the steps are as follows:

[0034] (1) Heat 62 parts by mass of rubber oil to 140°C, add 3 parts by mass of EVA modifier and cut with a shear for 45 minutes. Then at 70°C, add 3 parts by mass of aluminum-zirconium coupling agent LD 139, ultrasonically disperse for 75 minutes, then add 2 parts of polyphosphoric acid and stir for 100 minutes at 140°C to prepare Component A.

[0035] (2) Heat 27.5 parts by mass of water to 30°C, add 0.5 parts by mass of slow-cracking and fast-setting cationic emulsifier PRAC417, 0.5 parts by mass of slow-cracking and fast-setting cationic emulsifier MQ65 and 1.5 parts by mass of dilute Sulfuric acid, stirred until the flocs disappeared, the pH was adjusted to 1.8, and emulsion B was prepared.

[0036] (3) Heat component A to 100°C, then add emulsion B, and emulsify and shear at 4000 rpm for 30 minutes at 90°C to prepare emulsified regenerant C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com