Method for extracting and removing dibenzothiophene

The technology of dibenzothiophene and extraction agent is applied in the field of extraction and removal of dibenzothiophene, which can solve the problems of complex ionic liquid process and high cost of raw materials, and achieve the effects of simple extraction method, high desulfurization efficiency and environmental friendliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

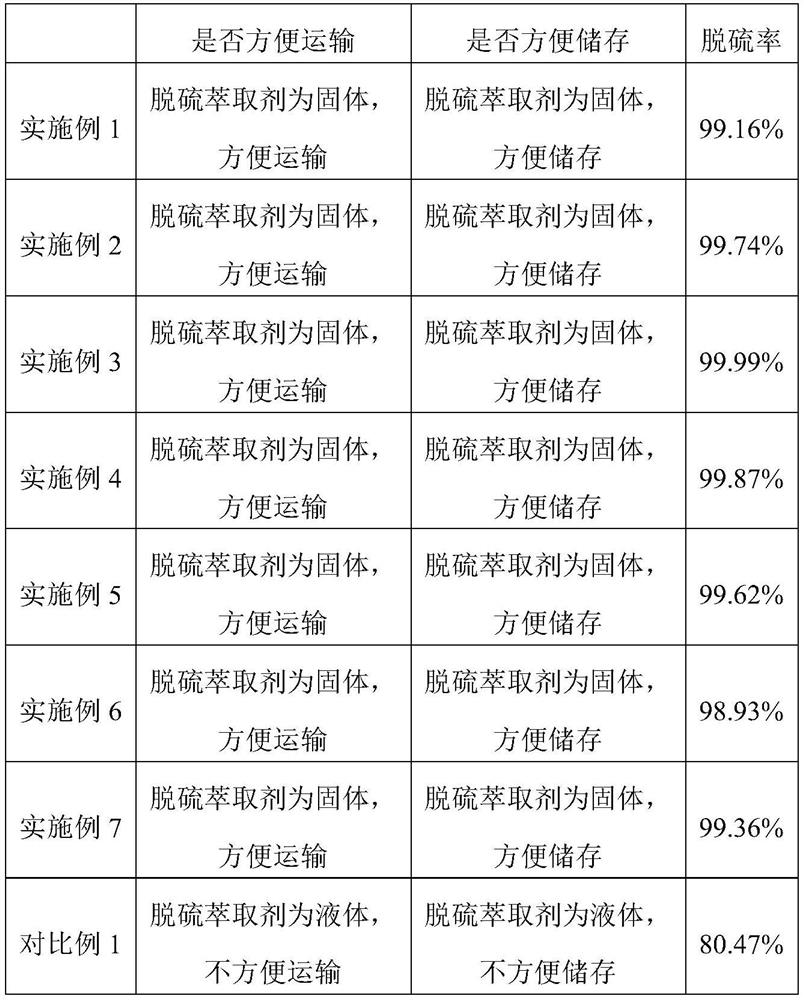

[0023] A preparation method of a desulfurization extractant, the preparation method is: tetrabutylammonium chloride and p-toluenesulfonic acid molar ratio is 1:2 to form 2g of deep eutectic solvent, and then the deep eutectic solvent Loaded onto 0.1 g of reduced graphene oxide to obtain a desulfurization extractant, the evaluation results of its transportation and storage are shown in Table 1 below.

[0024] Utilize the method for extracting dibenzothiophene with the above-mentioned desulfurization extractant, described method is: the dibenzothiophene n-octane solution that 0.5g concentration is 1600ppm, 0.15g desulfurization extractant and 0.05g 30% hydrogen peroxide solution at 25 Stir at 800 rpm for 60 min at °C, and after standing to separate layers, detect the concentration of dibenzothiophene in the n-octane layer by gas chromatography. The desulfurization rate is shown in Table 1 below.

Embodiment 2

[0026] A preparation method of a desulfurization extractant, the preparation method is: tetrabutylammonium chloride and p-toluenesulfonic acid molar ratio is 1:2 to form 2g of deep eutectic solvent, and then the deep eutectic solvent Loaded onto 0.1 g of reduced graphene oxide to obtain a desulfurization extractant, the evaluation results of its transportation and storage are shown in Table 1 below.

[0027] Utilize the method for extracting dibenzothiophene with the above-mentioned desulfurization extractant, described method is: the dibenzothiophene n-octane solution that 0.5g concentration is 1600ppm, 0.25g desulfurization extractant and 0.05g 30% hydrogen peroxide solution at 25 Stir at 800 rpm for 60 min at °C, and after standing to separate layers, detect the concentration of dibenzothiophene in the n-octane layer by gas chromatography. The desulfurization rate is shown in Table 1 below.

Embodiment 3

[0029] A preparation method of a desulfurization extractant, the preparation method is: tetrabutylammonium chloride and p-toluenesulfonic acid molar ratio is 1:2 to form 2g of deep eutectic solvent, and then the deep eutectic solvent Loaded onto 0.1 g of reduced graphene oxide to obtain a desulfurization extractant, the evaluation results of its transportation and storage are shown in Table 1 below.

[0030] Utilize the method for extracting dibenzothiophene with the above-mentioned desulfurization extractant, described method is: the dibenzothiophene n-octane solution that 0.5g concentration is 1600ppm, 0.15g desulfurization extractant and 0.05g 30% hydrogen peroxide solution are in 60 Stir at 800 rpm for 60 min at °C, and after standing to separate layers, detect the concentration of dibenzothiophene in the n-octane layer by gas chromatography. The desulfurization rate is shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com