Homogenized optical fiber of multi-layer square structure

A homogenizing fiber, square technology, applied in the direction of multi-layer core/clad fiber, clad fiber, light guide, etc., can solve the problems of small effective mode area and large loss of flat-top beam, and achieve good coupling, The effect of large model area and large development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

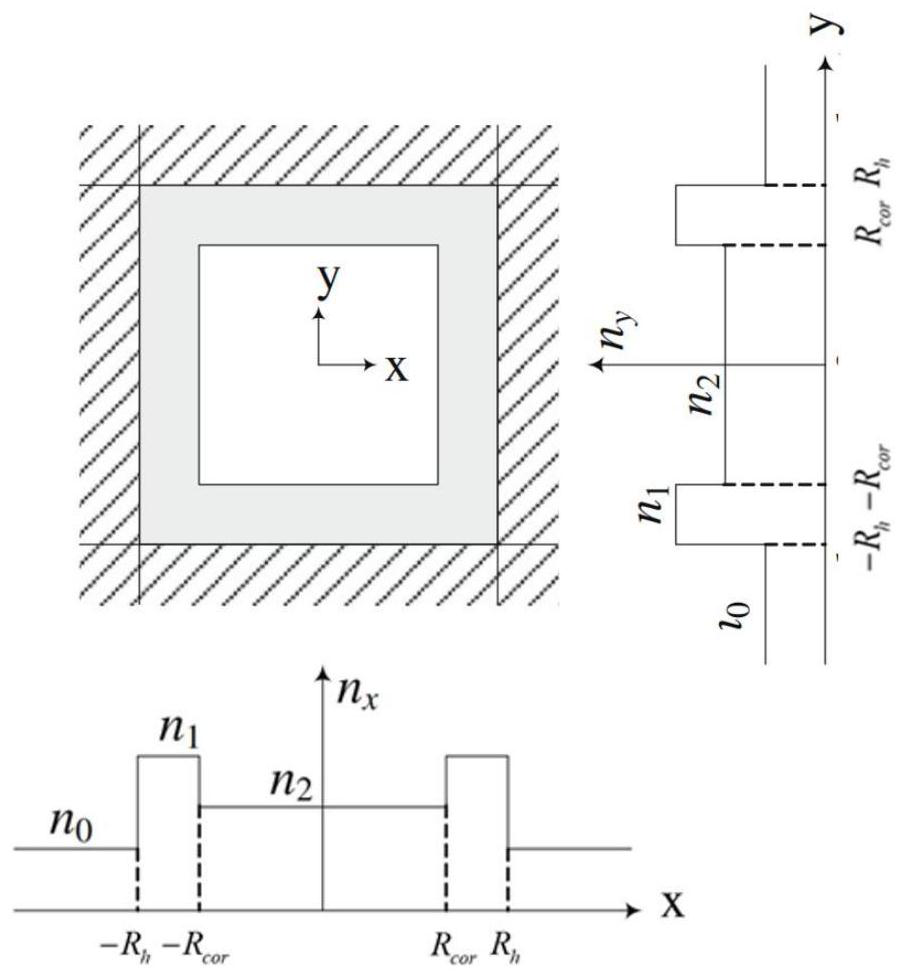

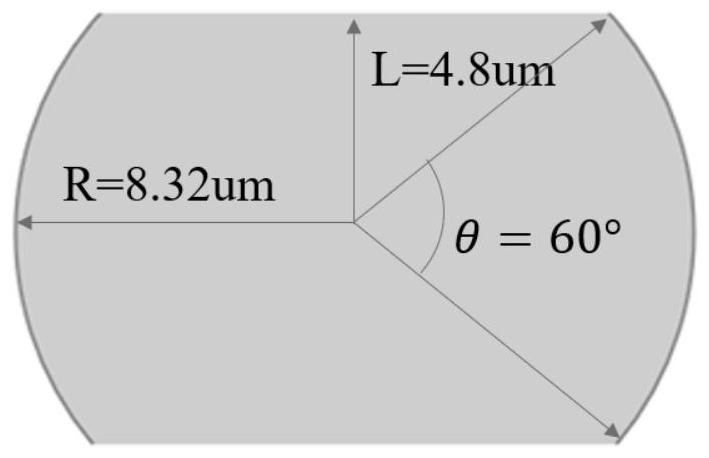

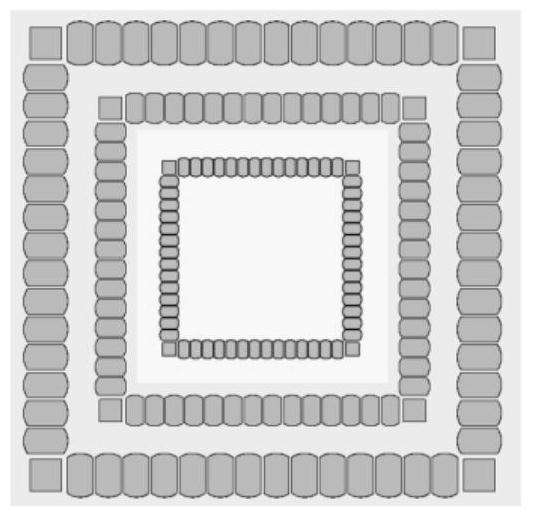

[0030] The invention discloses a homogenized optical fiber with a multilayer square structure, which includes a cladding and an inner fiber core. The cladding includes an air layer, and the air layer includes three layers, which are respectively a first air layer and a second air layer from outside to inside. layer and the third air layer, a doped layer is arranged outside the fiber core, the first air layer, the second air layer, the third air layer and the doped layer appear as a square whose size decreases successively, and the four vertices of the square are Square, other parts are sorted by multiple air holes or doping holes. The central doped layer is doped with different concentrations of GeO 2 , the innermost layer is ordinary quartz crystal. The initial value of the doping molar concentration in the doped region is set to 4.5%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com