Grain boundary diffusion preparation method of special neodymium-iron-boron permanent magnet for driving motor

A technology of grain boundary diffusion and driving motors, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, circuits, etc., can solve the problems of reducing the use of heavy rare earth elements, high requirements for environmental protection, and high cost of target material preparation. Good consistency, saving production costs, and optimizing the effect of microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a preparation method of grain boundary diffusion of NdFeB permanent magnets for drive motors, which comprises the following steps:

[0036] 1) Design two rare earth-rich auxiliary alloys with high dysprosium and high terbium content and a main phase alloy without dysprosium and terbium. The chemical formula of the main phase alloy is (PrNd) x Fe 100-x-z-n m z B n , where x, z, and n respectively represent the mass percentages of the corresponding elements in the formula, 29≤x≤32, 1≤z≤3, 0.92≤n≤1, M is one of Zr, Nb, Ga, Co, Al One or more elements; the chemical formula of high dysprosium auxiliary alloy is (PrNd) 20 Dy 20 Fe 60-z-n m z B n, where x, y, z, and n represent the mass percentages of the corresponding elements in the formula, 1≤z≤3, 0.92≤n≤1, M is one or more of Zr, Nb, Ga, Co, Al element; the chemical formula of high terbium auxiliary alloy is (PrNd) 30 Tb 10 Fe 60-z-n m z B n , where x, y, z, and n represent the mass perc...

Embodiment 2

[0059] Change the milling process in step 1) in Example 1, mix three kinds of alloy quick-setting sheets according to a certain ratio according to the design composition of the base material, and then put them into a hydrogen crushing furnace for hydrogen crushing to obtain a coarse powder of the base material; the follow-up process and Example 1 is the same, and its magnetic properties are shown in Table 2.

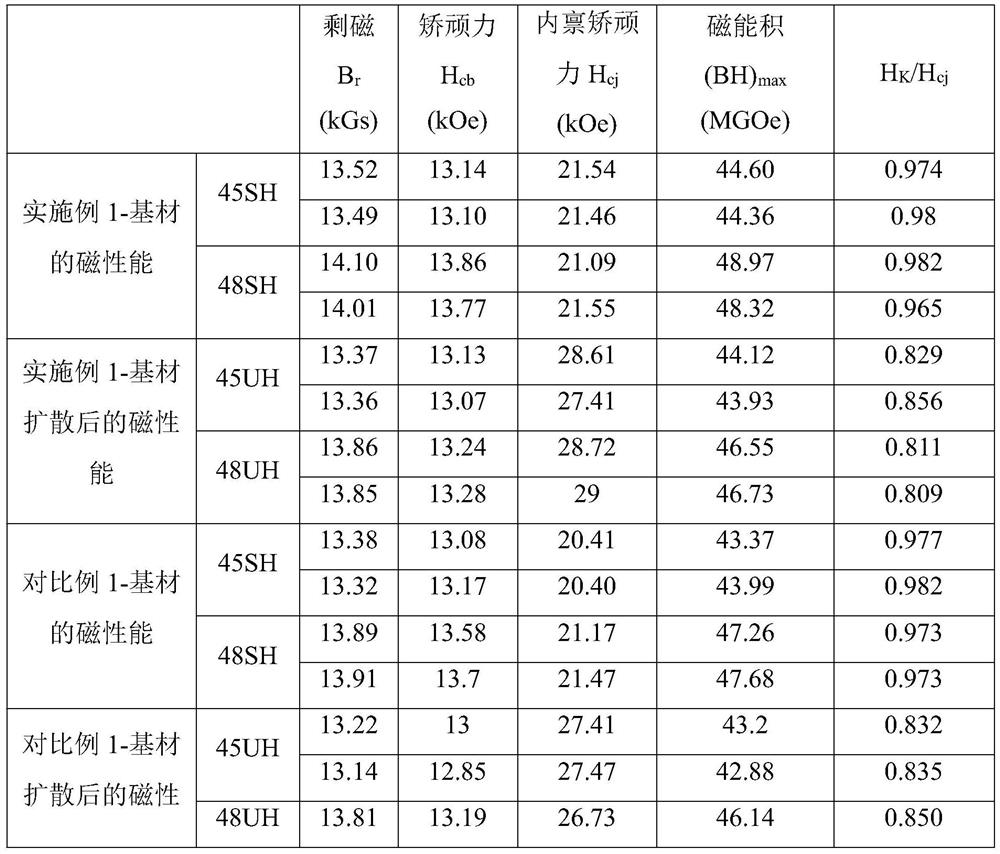

[0060] Table 2:

[0061]

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com