A flexible organic light-emitting device and its preparation method and display device

An organic light-emitting device, flexible technology, applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as difficulty in light extraction, reduce device efficiency, etc., to increase light extraction rate, eliminate total reflection, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

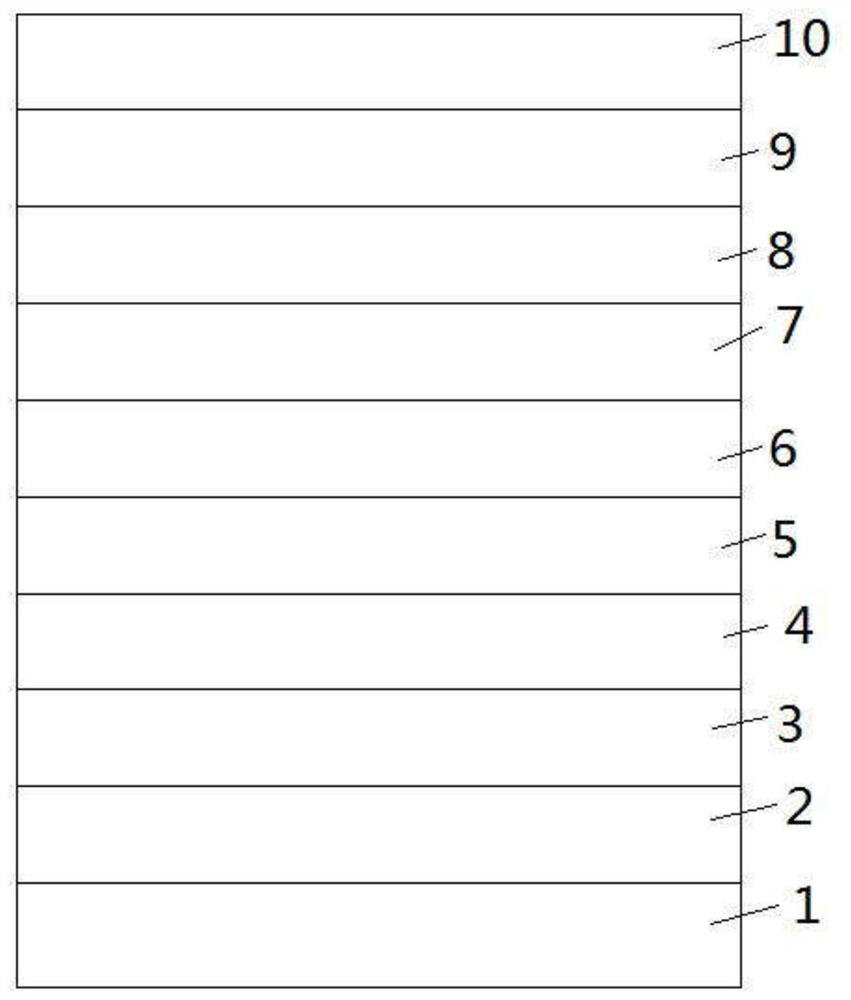

[0050] as attached figure 1 As shown, this embodiment provides a flexible organic light-emitting device, and its specific preparation method includes the following steps:

[0051] S1. Use transparent glass with ITO on the surface as the substrate, then ultrasonically clean with deionized water, acetone, and ethanol for 15 minutes each, and then treat in a plasma cleaner for 2 minutes to obtain the first electrode 1 .

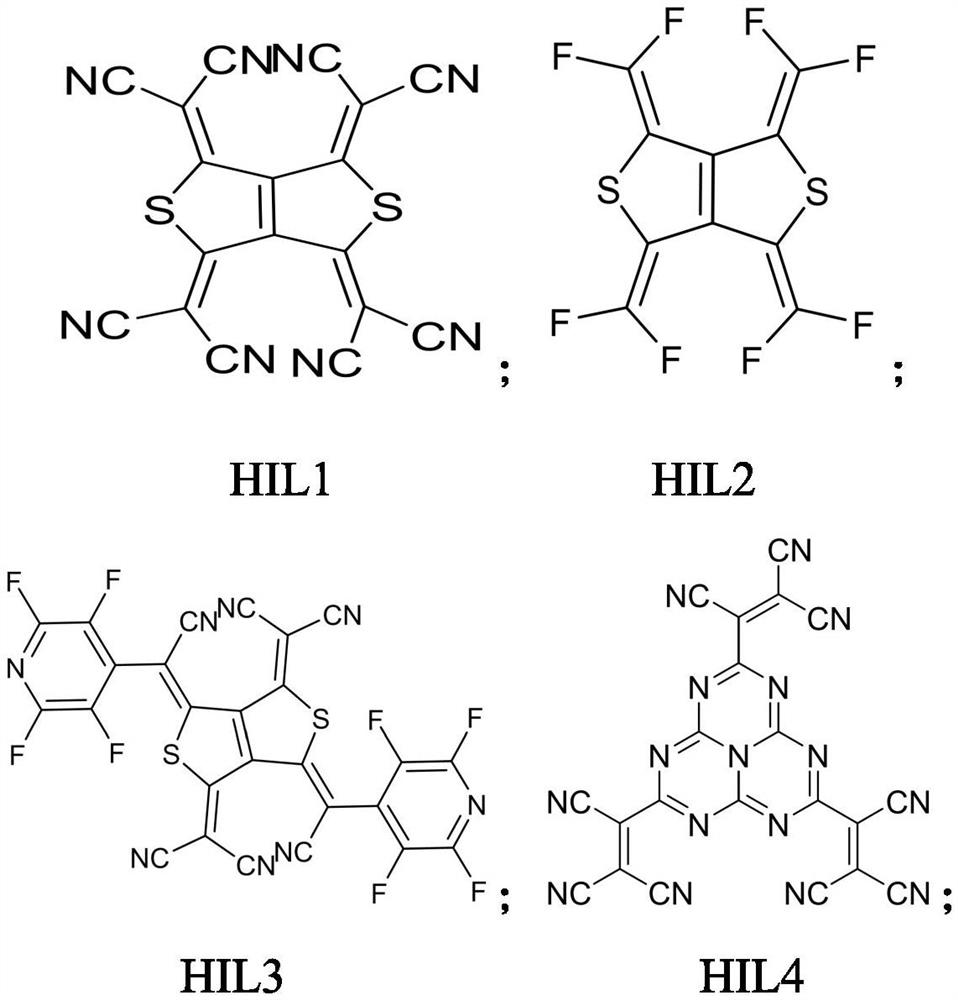

[0052] S2 , on the washed first electrode 1 , a hole injection material HIL1 is prepared by vacuum evaporation, with a thickness of 10 nm, as the hole injection layer 2 .

[0053] S3 . On the hole injection layer 2 , a hole transport material HTL1 is prepared by vacuum evaporation with a thickness of 125 nm as the hole transport layer 3 .

[0054] S4 , on the hole transport layer 3 , the electron blocking material EBL1 is prepared by vacuum evaporation with a thickness of 5 nm, which is used as the electron blocking layer 4 .

[0055] S5 , on the electron bloc...

Embodiment 2

[0061] as attached figure 1 As shown, this embodiment provides a flexible organic light-emitting device, and its specific preparation method includes the following steps:

[0062] S1. Use transparent glass with ITO on the surface as the substrate, then ultrasonically clean with deionized water, acetone, and ethanol for 15 minutes each, and then treat in a plasma cleaner for 2 minutes to obtain the first electrode 1 .

[0063] S2 , on the washed first electrode 1 , a hole injection material HIL1 is prepared by vacuum evaporation, with a thickness of 10 nm, as the hole injection layer 2 .

[0064] S3 . On the hole injection layer 2 , a hole transport material HTL1 is prepared by vacuum evaporation with a thickness of 125 nm as the hole transport layer 3 .

[0065] S4 , on the hole transport layer 3 , the electron blocking material EBL1 is prepared by vacuum evaporation with a thickness of 5 nm, which is used as the electron blocking layer 4 .

[0066] S5 , on the electron bloc...

Embodiment 3

[0072] as attached figure 1 As shown, this embodiment provides a flexible organic light-emitting device, and its specific preparation method includes the following steps:

[0073] S1. Use transparent glass with ITO on the surface as the substrate, then ultrasonically clean with deionized water, acetone, and ethanol for 15 minutes each, and then treat in a plasma cleaner for 2 minutes to obtain the first electrode 1 .

[0074] S2 , on the washed first electrode 1 , a hole injection material HIL1 is prepared by vacuum evaporation, with a thickness of 10 nm, as the hole injection layer 2 .

[0075] S3 . On the hole injection layer 2 , a hole transport material HTL1 is prepared by vacuum evaporation with a thickness of 125 nm as the hole transport layer 3 .

[0076] S4 , on the hole transport layer 3 , the electron blocking material EBL1 is prepared by vacuum evaporation with a thickness of 5 nm, which is used as the electron blocking layer 4 .

[0077] S5 , on the electron bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com