Method for improving seed decomposition rate in aluminum oxide production

A technology of decomposition rate and alumina, which is applied in the direction of alumina/aluminum hydroxide, alumina/hydroxide preparation, alkali metal aluminate/alumina/aluminum hydroxide preparation, etc., which can solve cumbersome procedures and flow cumbersome, difficult operation and other problems, to achieve the effect of improving decomposition efficiency, improving cycle efficiency and improving decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

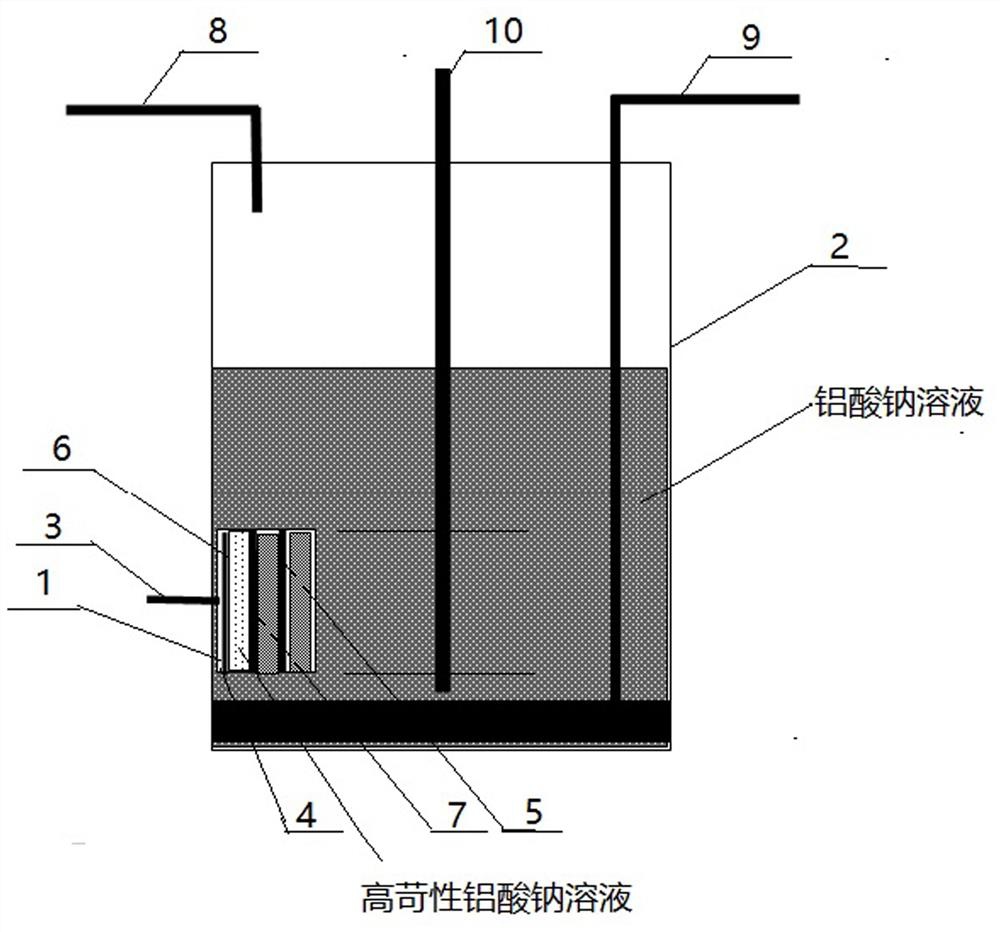

[0019] The electrodialysis device 1 is installed in the lower part of the decomposition tank 2 at a position slightly higher than the final deposition layer height of the aluminum hydroxide crystal, and the sodium aluminate solution (Na 2 O concentration is about 155g / L, Al 2 o 3 The concentration is about 159g / L, the caustic ratio is about 1.6) into the decomposition tank, turn on the agitator of the decomposition tank, keep warm at 45°C, add crystal seeds to the sodium aluminate solution at a seed ratio of 1.5 for intermittent decomposition, and start the electrodialysis device (current density 200A / m 2 ), high caustic ratio solution (Na 2 O concentration is about 155g / L, Al 2 o 3 The concentration is about 6g / L, the caustic ratio is 42.5) continuously discharged from the cathode area of the electrodialysis device to the alkali storage tank outside the decomposition tank, and the caustic ratio of the sodium aluminate solution is detected once every 20 minutes, and the ...

Embodiment 2

[0021] The electrodialysis device 1 is installed in the lower part of the decomposition tank 2 at a position slightly higher than the final deposition layer height of the aluminum hydroxide crystal, and the sodium aluminate solution (Na 2 O concentration is about 159g / L, Al 2 o 3 The concentration is about 154g / L, the caustic ratio is about 1.7) into the decomposition tank continuously, the agitator of the decomposition tank is turned on, and the temperature is kept at 45°C. The seed crystal is added to the sodium aluminate solution according to the seed ratio of 1.7 for continuous decomposition, and the electrodialysis is started. Device (current density 400A / m 2 ), high caustic ratio solution (Na 2 O concentration is about 160g / L, Al 2 o 3The concentration is about 7g / L, the caustic ratio is about 37.6) continuously discharged from the cathode area of the electrodialysis device into the alkali storage tank outside the decomposition tank, and the caustic ratio of the so...

Embodiment 3

[0023] The electrodialysis device 1 is installed in the lower part of the decomposition tank 2 at a position slightly higher than the final deposition layer height of the aluminum hydroxide crystal, and the sodium aluminate solution (Na 2 O concentration is about 158g / L, Al 2 o 3 The concentration is about 173g / L, the caustic ratio is about 1.5) into the decomposition tank continuously, turn on the agitator of the decomposition tank, keep warm at 45°C, add crystal seeds to the sodium aluminate solution at a seed ratio of 1.6 for continuous decomposition, and start electrodialysis Device (current density 600A / m 2 ), high caustic ratio solution (Na 2 O concentration is about 160g / L, Al 2 o 3 The concentration is about 9g / L, and the caustic ratio is about 29) Continuously discharged from the cathode area of the electrodialysis device to the alkali storage tank outside the decomposition tank, the caustic ratio of the sodium aluminate solution is detected once every 20 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com