High-glossiness coated paper and production process thereof

A technology with high gloss and production process, applied in the field of papermaking, can solve the problems of low gloss of coated paper, low surface water resistance, weak resistance to printing ink, etc., and achieve good covering ability, gloss improvement, whiteness and water resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

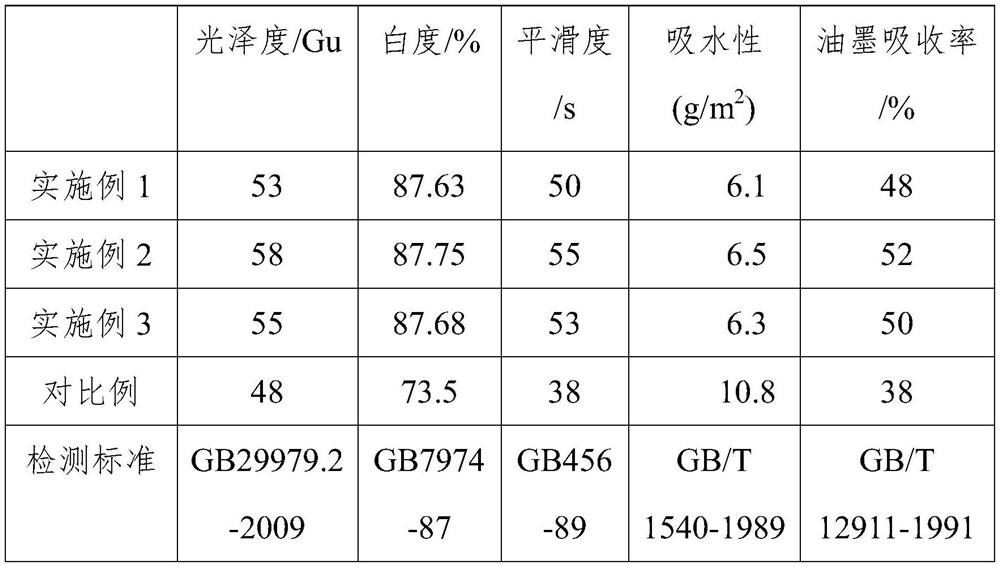

Examples

Embodiment 1

[0032] A high-gloss coated paper and its production process, comprising the following steps:

[0033] Ⅰ. Weigh an appropriate amount of long-fiber pulp and short-fiber pulp according to the mass ratio of 1.2:1.0, and mix and prepare the two, then pour the mixed pulp into a heating container and boil to separate the fibers in the mixed pulp, and Purify the mixed pulp through the pressure screen, head box and wire part, and then pass through the pressing part for pressing, drying part for drying, coiling, slitting and other processes to obtain the base paper;

[0034] Among them, the moisture content of the base paper after being dried by the drying section is controlled at 3.0%;

[0035] Ⅱ. In parts by weight, weigh 40 parts of calcium hydroxide, 30 parts of barium sulfate, 15 parts of china clay, 5 parts of high-gloss paraffin, 15 parts of organic silicon and 5 parts of organic additives; then put the weighed materials into After mixing and stirring in the paint preparation b...

Embodiment 2

[0051] A high-gloss coated paper and its production process, comprising the following steps:

[0052] Ⅰ. Weigh appropriate amount of long-fiber pulp and short-fiber pulp according to the mass ratio of 1.3:1.0, and mix and prepare the two, then pour the mixed pulp into a heating container and boil to separate the fibers in the mixed pulp, and Purify the mixed pulp through the pressure screen, head box and wire part, and then pass through the pressing part for pressing, drying part for drying, coiling, slitting and other processes to obtain the base paper;

[0053] Among them, the moisture content of the base paper after being dried by the drying section is controlled at 3.5%;

[0054] Ⅱ. In parts by weight, weigh 42 parts of calcium hydroxide, 35 parts of barium sulfate, 20 parts of china clay, 10 parts of high-gloss paraffin, 10 parts of organic silicon and 6 parts of organic additives; then put the weighed materials into After mixing and stirring in the paint preparation bar...

Embodiment 3

[0070] A high-gloss coated paper and its production process, comprising the following steps:

[0071] Ⅰ. Weigh appropriate amount of long-fiber pulp and short-fiber pulp according to the mass ratio of 1.5:1.0, and mix and prepare the two, then pour the mixed pulp into a heating container and boil to separate the fibers in the mixed pulp, and Purify the mixed pulp through the pressure screen, head box and wire part, and then pass through the pressing part for pressing, drying part for drying, coiling, slitting and other processes to obtain the base paper;

[0072] Among them, the moisture content of the base paper after being dried by the drying section is controlled at 4.0%;

[0073] Ⅱ. In parts by weight, weigh 45 parts of calcium hydroxide, 43 parts of barium sulfate, 25 parts of china clay, 15 parts of high-gloss paraffin, 25 parts of organic silicon and 8 parts of organic additives; then put the weighed above-mentioned materials into After mixing and stirring in the pigme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com