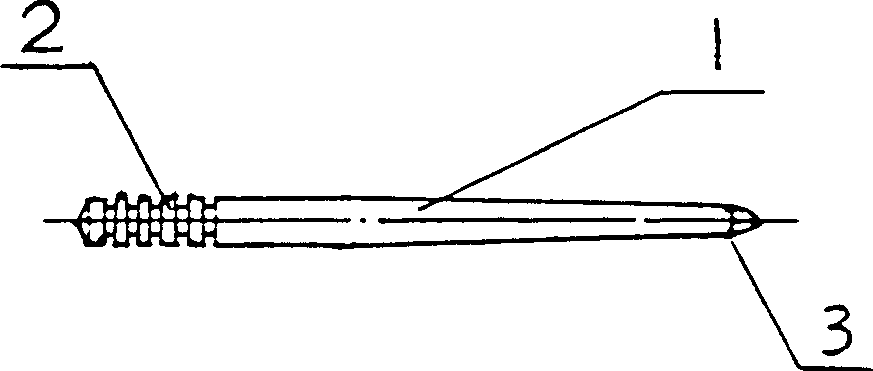

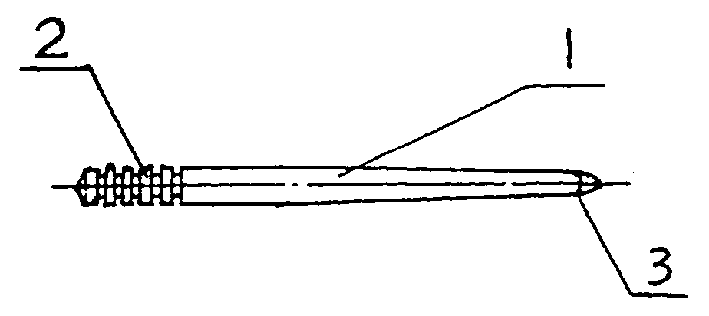

Aluminium oil needle for carburettor plunger of motorcycle and its manufacture

A manufacturing method and technology of carburetors, applied in carburetors, anodizing, machines/engines, etc., can solve problems such as increased fuel consumption, excessive exhaust emissions, size changes, and unstable idle speed of motorcycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In the specific design and manufacture of the present invention, metal raw materials such as iron, lithium, manganese and silicon can also be added to the formula of the oil needle base material, and the ratio of the weight parts of each raw material added to the weight part of aluminum in the specific formula It is: aluminum: iron: lithium: manganese: silicon = 97-99.5: 0.10-0.40: 0.02-0.10: 0.02-0.10: 0.20-0.60.

[0010] When the present invention adopts the process steps of the aforementioned method for manufacturing, the chemical degreasing process step refers to immersing the refined oil needles in a mixture of phosphoric acid and strong acid at a certain concentration, wherein the phosphoric acid and strong acid (As sulfuric acid, hydrochloric acid, nitric acid etc.) the ratio of parts by weight is; Phosphoric acid: strong acid=40~60:10~20. The strong acid can be commercially available industrial sulfuric acid, hydrochloric acid or nitric acid, etc., and the tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com