Ultrasonic synthesis method and application of spiral ferronickel supramolecular network framework nano composite material

A nanocomposite material and network framework technology, applied in ultrasonic synthesis method and application field, can solve the problems of low reversibility of cathode oxygen reduction reaction, high cost of Pt-based catalytic materials, low exchange current density, etc., and achieve excellent methanol tolerance. , excellent stability, outstanding effect of onset potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

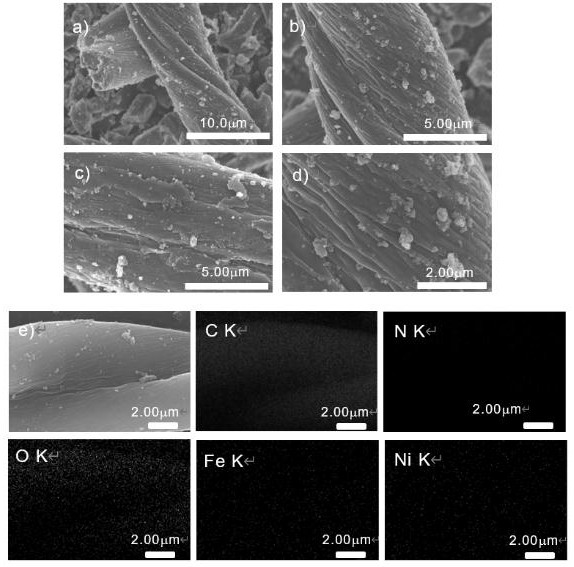

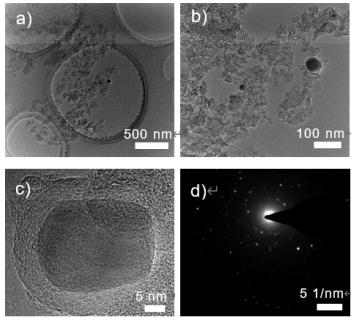

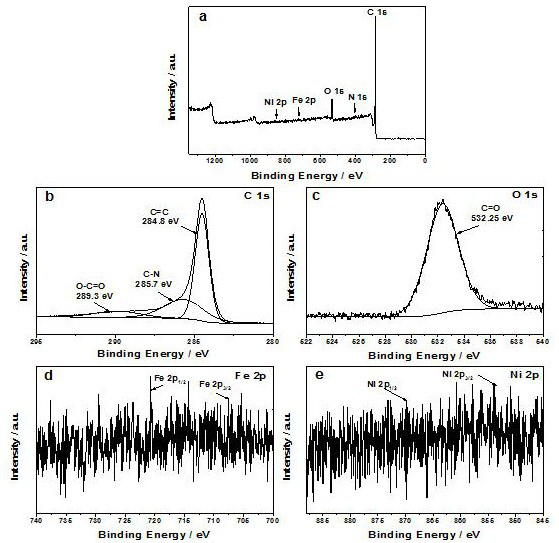

[0033] This example shows a C@NiFe with helical structure 2 o 4 synthetic method.

[0034] (1) Weigh a certain amount of directly bought cellulose and put it into a conical flask filled with deionized water. Next, adjust the pH value of the solution system to 1.0 to 2.0 with a buffered acid solution 2M HCl solution. The bottle is sealed with plastic wrap and placed in a water bath shaker to vibrate to achieve the purpose of opening the cellulose compacting system, and washed with water for later use;

[0035] (2) Fully dissolve ferric nitrate nonahydrate and nickel nitrate hexahydrate in deionized water respectively, pour into cellulose and stir for 10 minutes (the mass ratio of the three raw materials is 1:6:1.5 in turn), and then pour 10mg / Put 1 mL of plant polyphenol solution into the ultrasonic machine after fully mixing, control the ultrasonic output power at about 200W, and control the temperature at (40±1)°C, so that the solution is evenly dispersed in the pretreated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com