Continuous preparation method of 4-nitrosoantipyrine

A technology of nitrosoantipyrine and antipyrine, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problem of increased reaction time by-products, many impurities in the product, and cumbersome purification process, etc. problems, to achieve the effect of easy processing, simple purification process and reduced purification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The invention provides a continuous preparation method of 4-nitrosoantipyrine, the preparation method comprising the following steps:

[0046] Step S1, preparing an antipyrine sulfate solution.

[0047] Antipyrine and dilute sulfuric acid are added into a reaction kettle to prepare an antipyrine sulfate solution.

[0048] In a specific embodiment of the present invention, the mass concentration of the antipyrine sulfate solution prepared in step S1 is 30-40% (such as 31%, 32%, 33%, 34%, 35%, 36%, 37% , 38%, 39%).

[0049] Preferably, the mass concentration of the antipyrine sulfate solution prepared in step S1 is 32-36% (such as 33%, 34%, 35%).

[0050] Step S2, preparing an aqueous solution of sodium nitrite.

[0051] In a specific embodiment of the present invention, the mass concentration of the sodium nitrite aqueous solution prepared in step S2 is 15-20% (such as 16%, 17%, 18%, 19%).

[0052] Preferably, the mass concentration of the sodium nitrite aqueous soluti...

Embodiment 1

[0081] This embodiment provides a continuous preparation method of 4-nitrosoantipyrine, the preparation method comprising the following steps:

[0082] Step S1, preparation mass concentration is the antipyrine sulfate solution of 34%;

[0083] Step S2, preparing an aqueous sodium nitrite solution with a mass concentration of 18%;

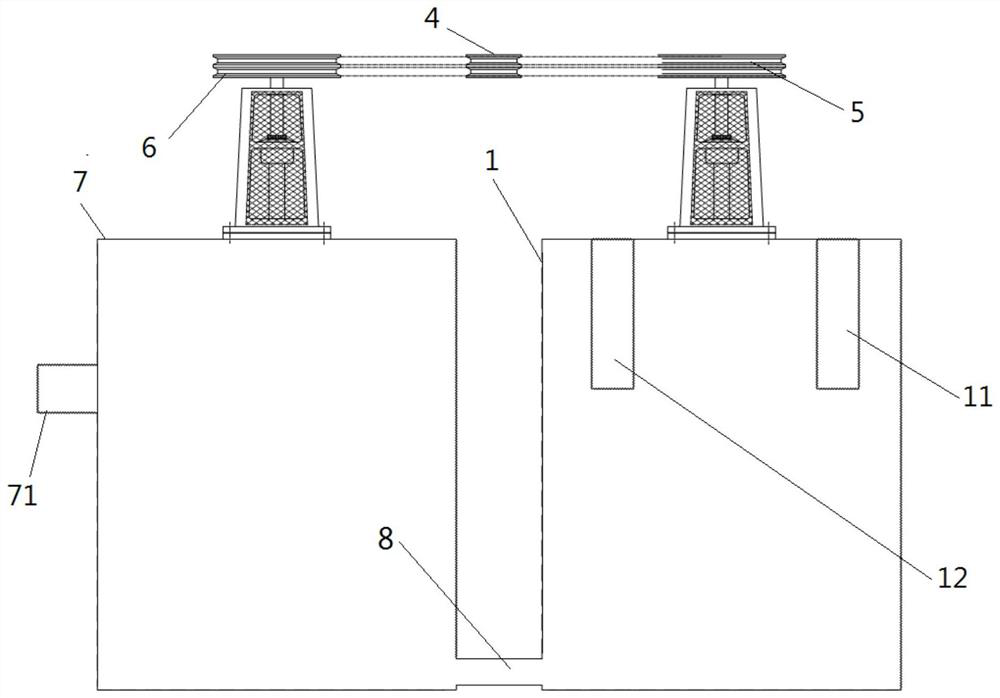

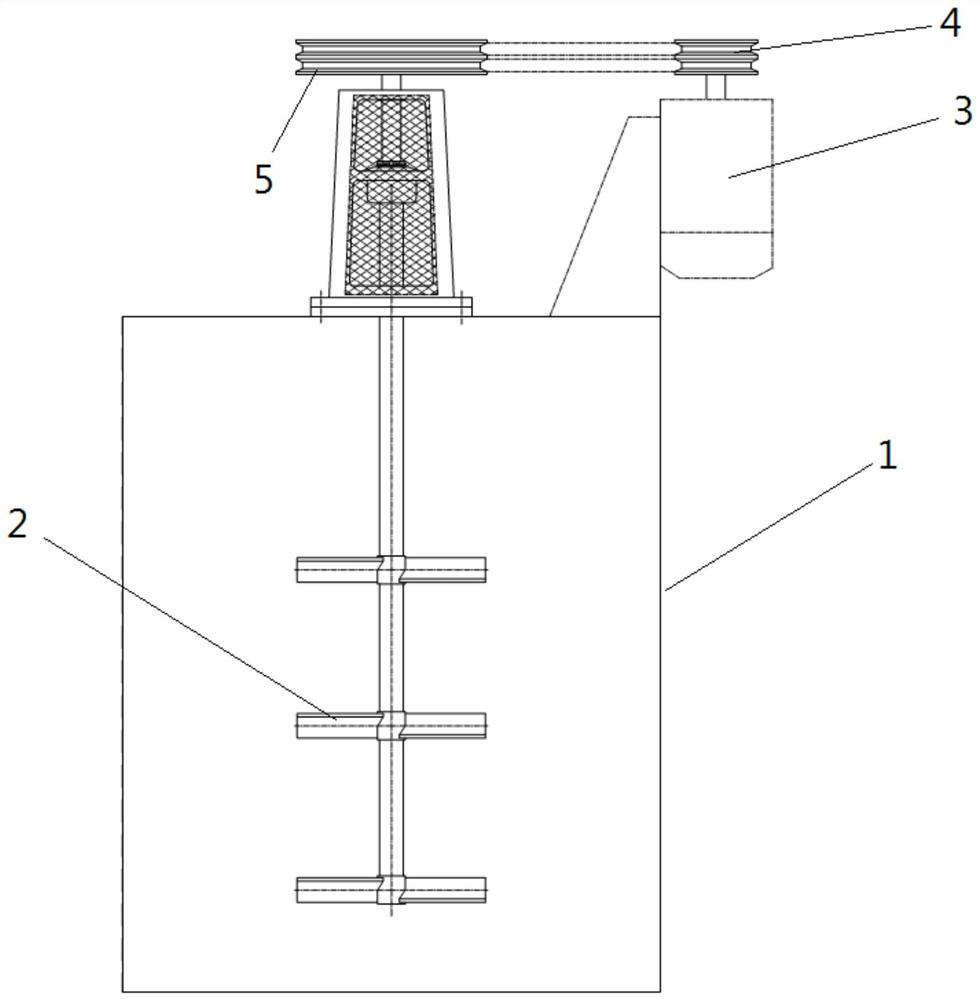

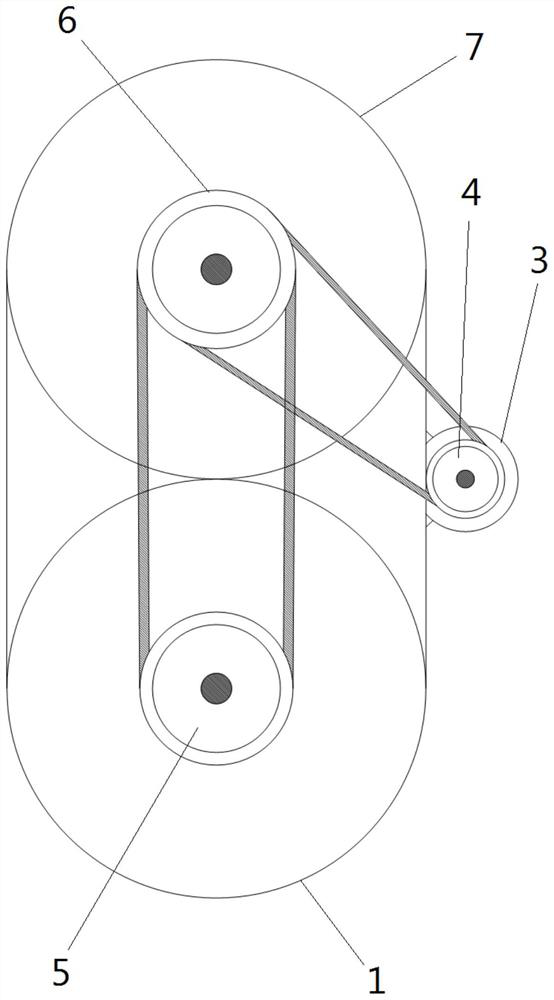

[0084] Step S3, adding the antipyrine sulfate solution and sodium nitrite aqueous solution prepared in steps S1 and S2 respectively in the feed tank through the antipyrine sulfate feed inlet 11 and the sodium nitrite feed inlet, respectively Control the feeding rate of antipyrine sulfate solution to be 1.35m 3 / h, the feed rate of sodium nitrite aqueous solution is 1.4m 3 / h, the temperature of reaction in the control feed tank is 50 DEG C, and the stirring speed of the first stirring device 2 is 218rpm, obtains semi-finished product 4-nitrosoantipyrine;

[0085] The semi-finished product 4-nitrosoantipyrine obtained in step S4 and step S3 enters...

Embodiment 2

[0088] This embodiment provides a continuous preparation method of 4-nitrosoantipyrine, the preparation method comprising the following steps:

[0089] Step S1, preparation mass concentration is the antipyrine sulfate solution of 32%;

[0090] Step S2, preparing an aqueous sodium nitrite solution with a mass concentration of 18%;

[0091] Step S3, adding the antipyrine sulfate solution and sodium nitrite aqueous solution prepared in steps S1 and S2 respectively in the feed tank through the antipyrine sulfate feed inlet 11 and the sodium nitrite feed inlet, respectively Control the feeding rate of antipyrine sulfate solution to be 1.2m 3 / h, the feed rate of sodium nitrite aqueous solution is 1.2m 3 / h, the temperature of reaction in the control feed tank is 50 DEG C, and the stirring speed of the first stirring device 2 is 220rpm, obtains semi-finished product 4-nitrosoantipyrine;

[0092] The semi-finished product 4-nitrosoantipyrine obtained in step S4 and step S3 enters ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com