Intelligent monitoring system for milling chatter of numerical control milling machine

A technology for intelligent monitoring and milling chatter, which is applied in the field of CNC milling machine chatter intelligent monitoring system, which can solve the problems of noise pollution, tool wear, inability to improve production efficiency, etc., and achieve the effect of reducing damage, avoiding losses and dangers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

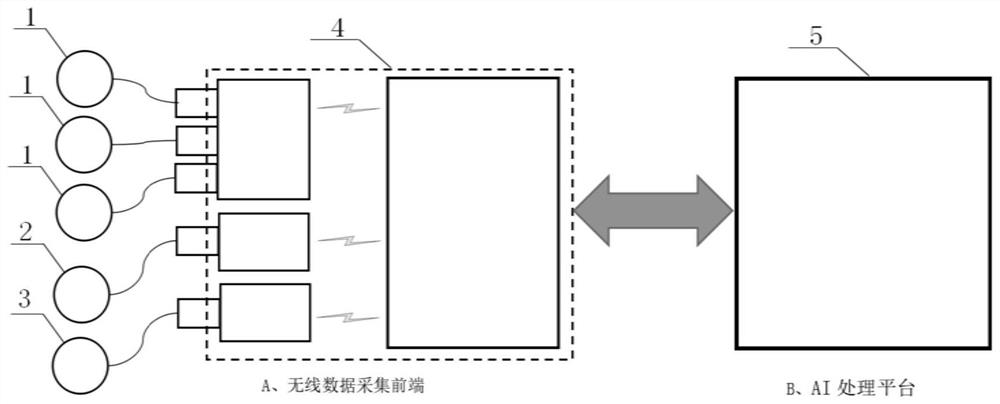

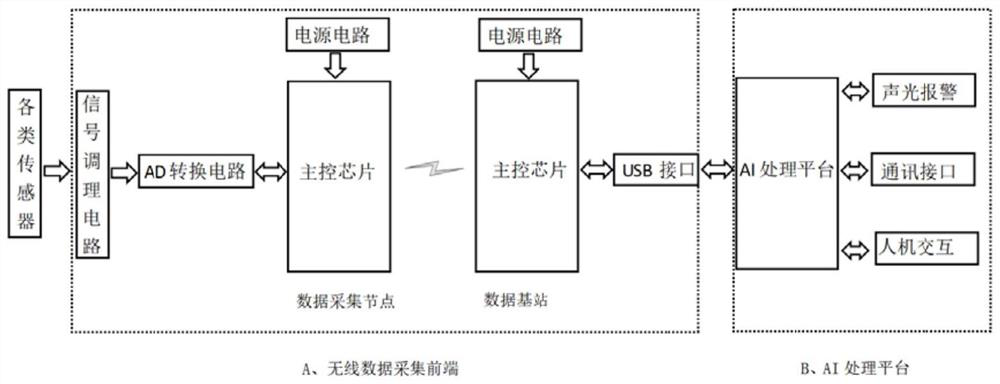

[0023] Such as figure 1 As shown, the present invention provides a kind of CNC milling machine milling chatter intelligent monitoring system:

[0024] Including acceleration sensor (1), sound sensor (2), current sensor (3), wireless data acquisition front end (4), AI processing platform (5); acceleration sensor, sound sensor, current sensor will transmit the collected data through the signal line For the wireless data acquisition front-end, the data base station of the wireless data acquisition front-end processes the data, and after processing, it is packaged and sent to the AI processing platform composed of RK3399Pro artificial intelligence processor through USB, and the online model training is performed on the data through TensorFlow to obtain the most The optimal deep learning model is deployed on the RK3399Pro platform.

[0025] The hardware of the system consists of an acceleration sensor (1), a sound sensor (2), a current sensor (3), a wireless data acquisition fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com