Method for treating iron-containing dust of iron and steel plant

A technology for iron and steel plants and dust, applied in the field of iron-containing dust treatment in iron and steel plants, can solve the problems of high cost, low efficiency and large investment, and achieve the effects of small investment, high efficiency and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

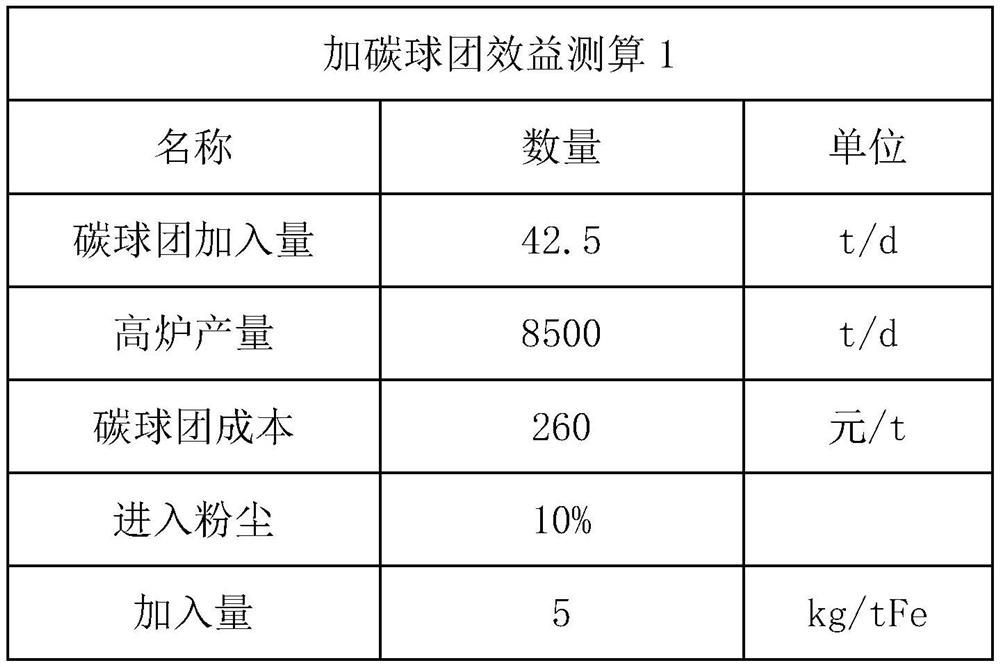

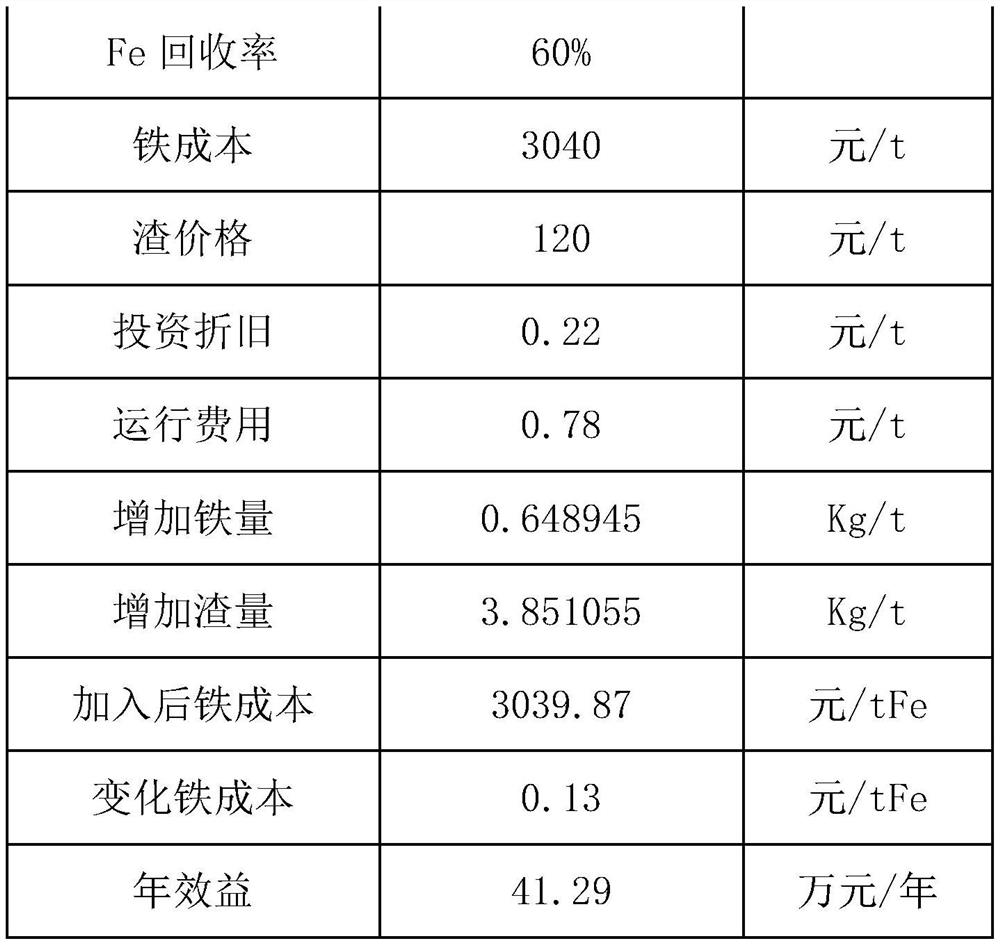

Examples

Embodiment Construction

[0028] The present invention aims at treating the dust with the rotary hearth furnace and the rotary kiln in the prior art, and the products obtained by processing the dust are metallized charge and dust enriched with harmful elements; the direct reduction process has large investment, low efficiency, high cost and the obtained sponge iron is also It is a method developed to deal with iron-containing dust in iron and steel plants due to the disadvantages of further melting treatment.

[0029] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

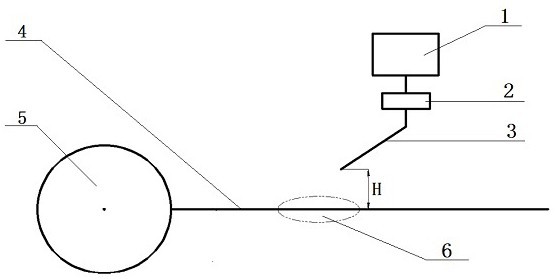

[0030] Such as figure 1 Shown, a kind of method for processing iron and steel plant iron-containing dust, comprises the following steps:

[0031] Step 1, mix the iron-containing dust and binder of the iron and steel plant with a mixer according to the ratio, and briquetting the mixture to prepare carbon pellets;

[0032] The iron-containing dust of the iron and steel pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com