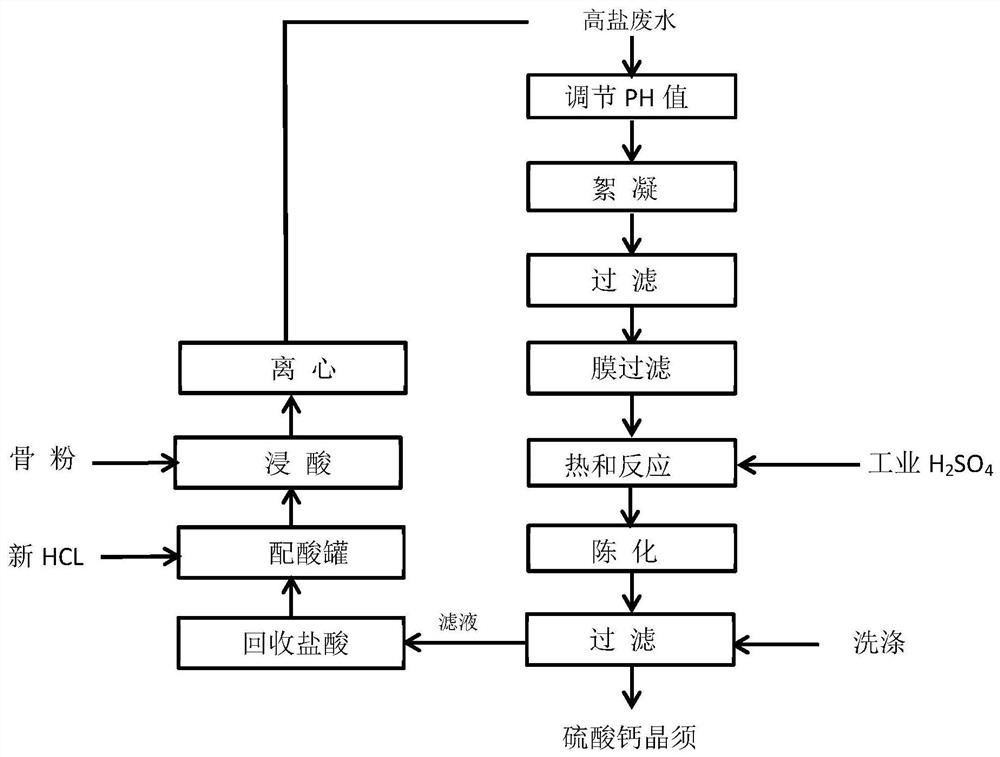

Method for producing calcium sulfate whiskers by using high-chlorine wastewater generated in bone gelatin production

A calcium sulfate whisker, high chloride technology, applied in chemical instruments and methods, single crystal growth, crystal growth and other directions, can solve the problems of microbial death, cell water loss, plasmolysis, etc., to achieve simple process and ease mining. Effects of pressure, short cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1. the method for the production of calcium sulfate whiskers from high-chloride waste water

[0041] 1) Take 37.5L of high-chloride waste water and pour it into a bucket, add 750ml of lime milk (specific gravity 1.18) to adjust the pH value to 7.0, and obtain the liquid to be treated;

[0042] 2) Add 180 ml of flocculant PAC (10%) to the liquid to be treated in step 1), stir for 5 s, add 18 ml of flocculant PAM (0.1%), and stir for 10 s to obtain flocculant;

[0043] 3) filter the flocculation liquid in step 2) with a 300-mesh filter bag, and collect the flocculation filtrate;

[0044] 4) Filter the flocculation filtrate collected in step 3) with a 2KD-3KD organic membrane device, collect 34L of filtrate, and detect COD2045ppm and calcium chloride content of 61.1g / L

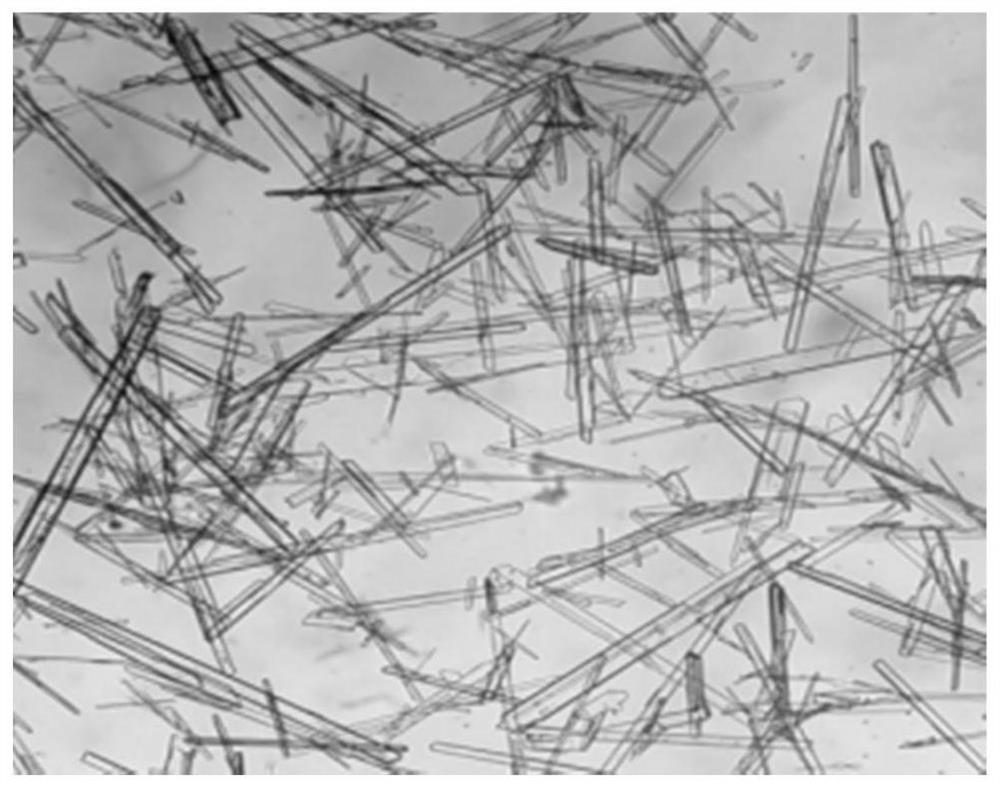

[0045] 5) Take 1000ml of the clear liquid collected in step 4) and put it in a 2000ml beaker and heat it to boil on an electric furnace. The measured temperature is 92°C. Cover the beaker with a ...

Embodiment 2

[0051] Embodiment 2. The method for producing calcium sulfate whiskers from high-chloride waste water.

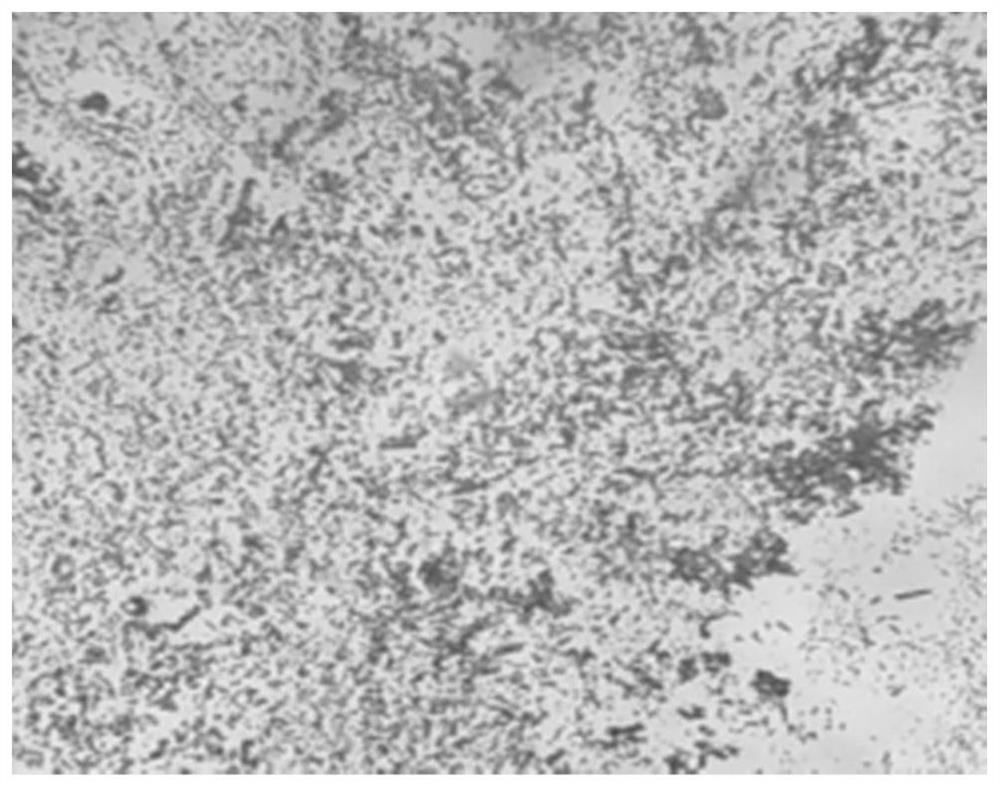

[0052] It is different from Example 1 in that it directly enters the next step without going through the aging process.

[0053] 1) Take 1000ml of the clear liquid collected in step 4) of Example 1 in a 2000ml beaker and heat it to boil on an electric furnace. The measured temperature is 92°C. Cover the beaker with a rubber plate and leave a feeding hole. Add 19ml of 96% sulfuric acid solution, heat and react to obtain a salt solution containing calcium sulfate;

[0054] 2) The calcium sulfate salt solution obtained in step 1) is directly filtered with a suction filter bottle, and about 1000ml of the clear liquid is collected, which can be recycled (soaked in bone meal), and the hydrochloric acid content is detected to be 3.72%; the obtained crystals are washed with 300ml of clear water at 50°C Two times, 150ml each time; after drying, dry the crystals in an oven at 105°C ...

Embodiment 3

[0056] Embodiment 3. the method for the production of calcium sulfate whiskers from high-chloride waste water

[0057] 1) Get 1000ml of high-chloride waste water and pour it into a 2000ml beaker, add 20ml of milk of lime (specific gravity 1.18) to adjust the pH value to 7.0, and obtain the liquid to be treated;

[0058] 2) Add 5 ml of flocculant PAC (10%) to the liquid to be treated in step 1), stir for 5 seconds, add 0.5 ml of flocculant PAM (0.1%), and stir for 10 seconds to obtain flocculant;

[0059] 3) filter the flocculation liquid in step 2) with a 300-mesh filter bag, and collect the flocculation filtrate;

[0060] Detect COD1989ppm, calcium chloride content is 61.9g / L

[0061] 4) The flocculated filtrate collected in step 3) was heated and boiled on an electric furnace, and the measured temperature was 91 ° C. The beaker was covered with a rubber plate and a feeding hole was left, and 19 ml of 96% sulfuric acid solution was slowly added to it under the condition of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com