A kind of composite matrix of vinegar residue biochar

A bio-waste and material technology, applied to fertilizers made from bio-waste, fertilizer mixtures, agriculture, etc., can solve problems such as changing the nutrient form in the nutrient solution, affecting nutrient absorption, and destroying chemical balance, so as to promote growth, The effect of solving environmental pollution and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

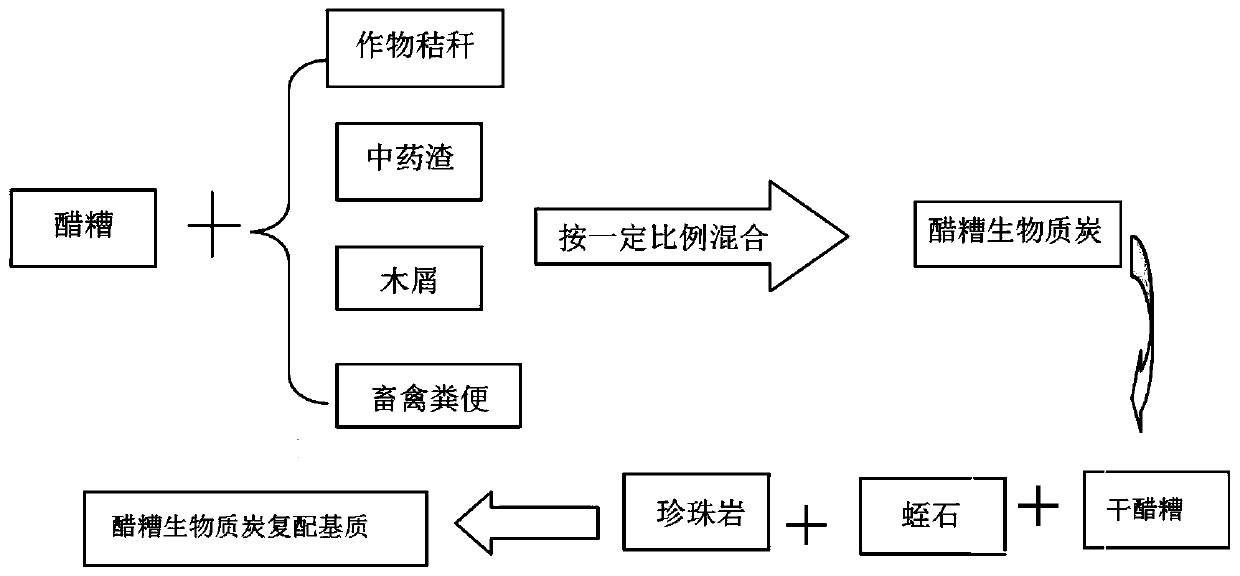

Method used

Image

Examples

Embodiment 1

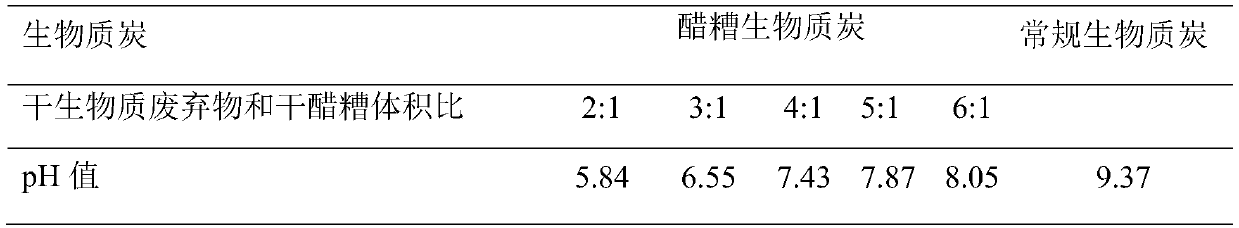

[0035] Collect wheat straw as biomass waste, keep the collected vinegar grains and biomass waste at room temperature for air-drying or air drying, so that the water content of vinegar grains and biomass waste is reduced to below 20%, and then press the following volume Mix the obtained dry vinegar grains with dry biomass waste, carbonize at 350-500°C for 2-4 hours under anaerobic conditions, cool, grind, and sieve to obtain vinegar grains biochar with a particle size of 1-5mm , the pH of the prepared vinegar residue biochar is shown in Table 1. It can be seen from the table that adding biomass and a certain proportion of vinegar grains for anaerobic pyrolysis can significantly reduce the pH of biochar, and with the increase of the proportion of vinegar grains, the pH of biochar gradually decreases.

[0036] Table 1 pH value of different biochars

[0037]

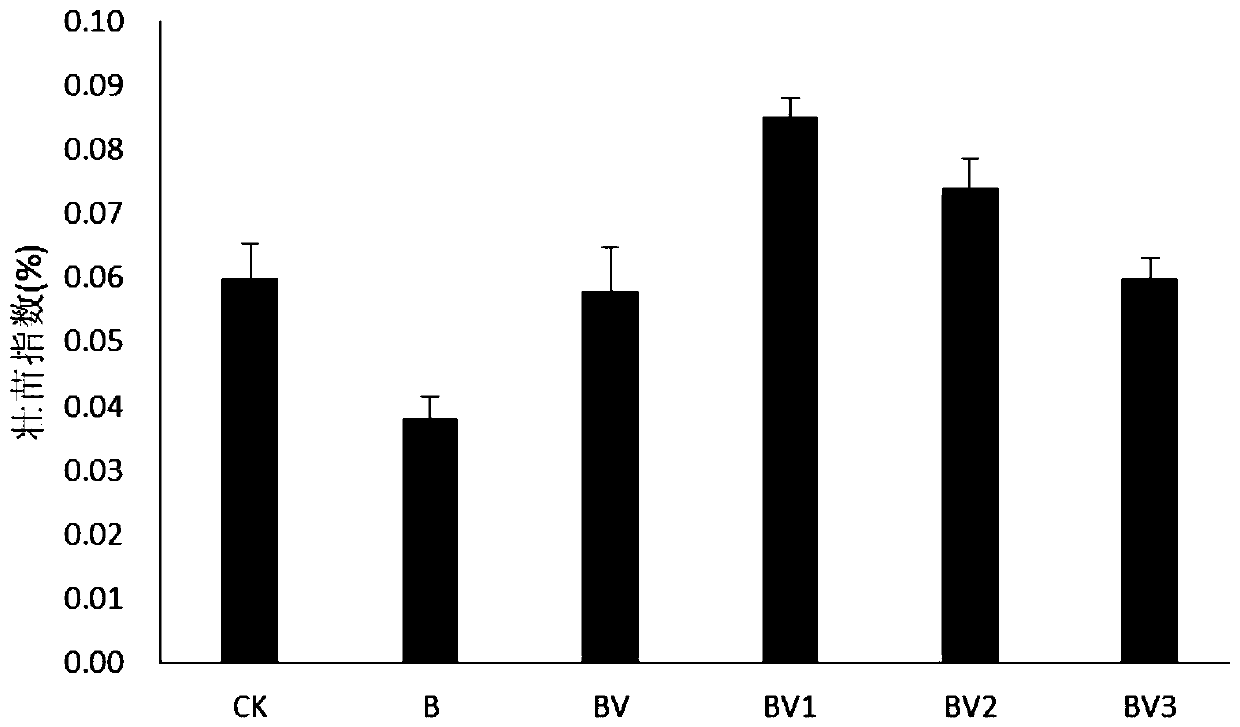

[0038] Effects of Substrate Components on Plant Growth

Embodiment 2

[0039]Embodiment 2 is contrasted with the matrix CK of adding peat and the matrix B of conventional biomass charcoal, with adding the dried vinegar grains of different proportions to coordinate the preparation series of vinegar grains biomass charcoal compound matrix (BV, BV1, BV2, BV3) as The experimental objects, the specific proportions are shown in Table 2.

[0040] Table 2 Volume ratio of matrix raw materials (%)

[0041]

[0042] After soaking the pepper seeds in 55°C warm water, germinate them in a dark condition in a 30°C constant temperature incubator. After whitening, choose the seeds with the same uniformity for sowing. In , each treatment and control were repeated 3 times and arranged in random blocks. Water was irrigated with water before 9:00 a.m. every day, and no nutrient solution was added during the period. After 50 days, samples were taken to measure the above-ground and underground growth indicators of the seedlings.

[0043] 1. Pore characteristics of...

Embodiment 3

[0057] Experimental method: Collect agricultural wastes such as wheat straw, traditional Chinese medicine dregs, wood chips, and pig manure as biomass waste, and air-dry or air-dry the vinegar waste and the above-mentioned biomass wastes at room temperature, respectively, so that the vinegar waste and biomass When the moisture content of the waste is reduced to less than 20%, the wheat straw, traditional Chinese medicine slag, sawdust, pig manure and other substances are respectively prepared into vinegar waste biomass charcoal by anaerobic thermal cracking at 450°C in a carbonization furnace. At the same time, dry vinegar grains were mixed with dry biomass (20% water content) such as wheat straw, traditional Chinese medicine dregs, sawdust, pig manure at a volume ratio of 1:4, respectively, and the mixed biomass was passed through a carbonization furnace for 450 minutes. ℃ anaerobic thermal cracking to prepare vinegar residue biomass charcoal. Taking the matrix CK added with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com