Steel-ultrahigh-toughness concrete combined bridge deck slab based on steel bar truss connection

A steel truss, ultra-high toughness technology, used in bridges, bridge parts, bridge construction and other directions, can solve the problem of affecting the corrosion resistance and durability of bridge decks, increasing bridge structure repair and maintenance costs, difficult to guarantee construction quality and accuracy, etc. problems, to achieve the effect of improving the interface connection performance, the comprehensive cost advantage is obvious, and the construction accuracy is not guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

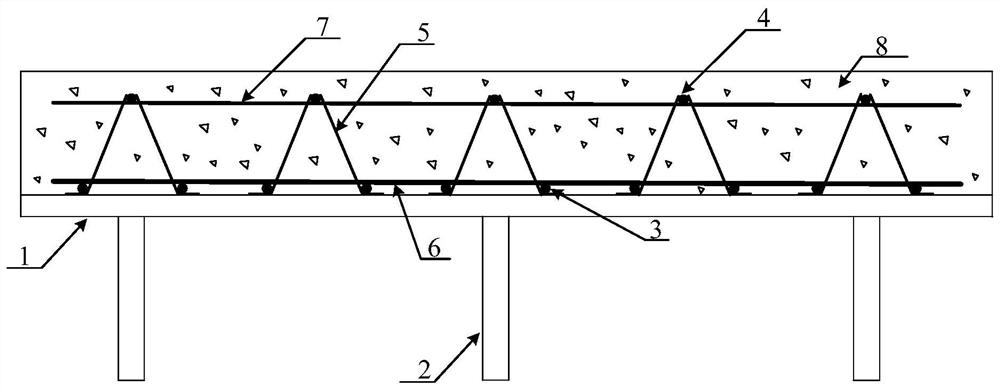

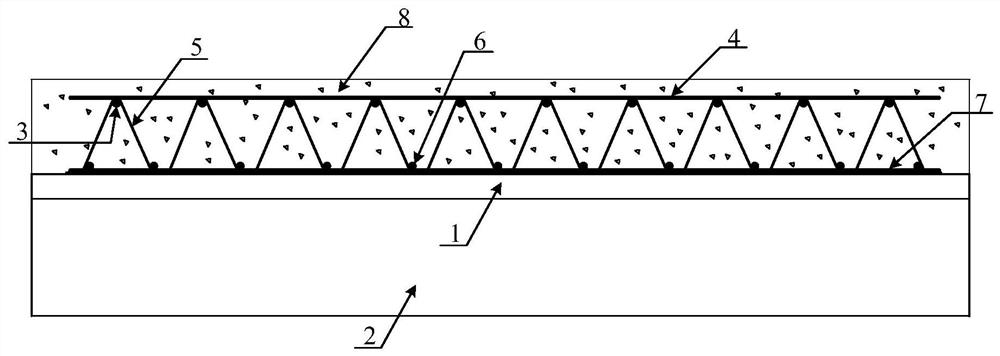

[0041] Such as Figure 1 to Figure 5 As shown, a steel-ultra-high toughness concrete composite bridge deck based on steel truss connections includes the following components: steel deck roof 1, longitudinal stiffeners 2, lower chord reinforcement 3, upper chord reinforcement 4, web reinforcement 5, lower 6 connecting steel bars, 7 upper connecting steel bars, and 8 ultra-high toughness concrete.

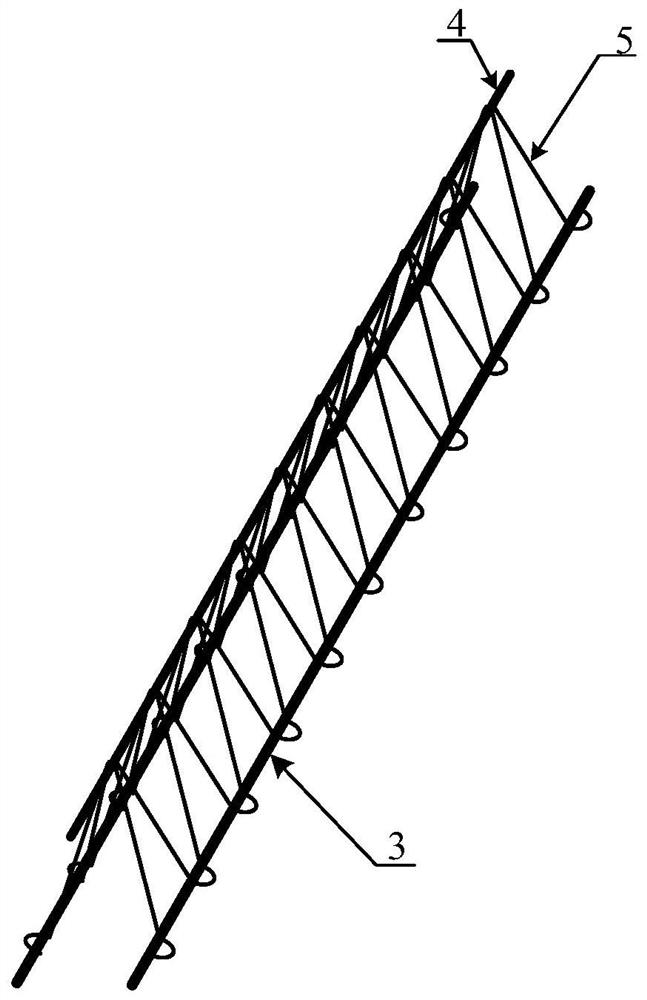

[0042] Such as figure 1As shown, a single web bar steel bar 5 can be divided into a main wave part and a bottom arc part after being pressed and formed, and the two parts form 120° with each other in the transverse direction. Two lower chord steel bars 3 are respectively welded at the bottom of the wavy part of the main body of the two web steel bars 5 slightly higher than the arc part, and the upper chord steel bar 4 is welded between the vertices of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com