Comprehensive pipe gallery adopting jetted ultrahigh-toughness cement-based composite material and construction method of comprehensive pipe gallery

A composite material, ultra-high toughness technology, applied in water conservancy projects, infrastructure projects, artificial islands, etc., can solve problems such as increased structural cost, complex underground environment, increased structural failure, etc., to reduce construction costs and ensure synergistic stress , the effect of improving the force performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

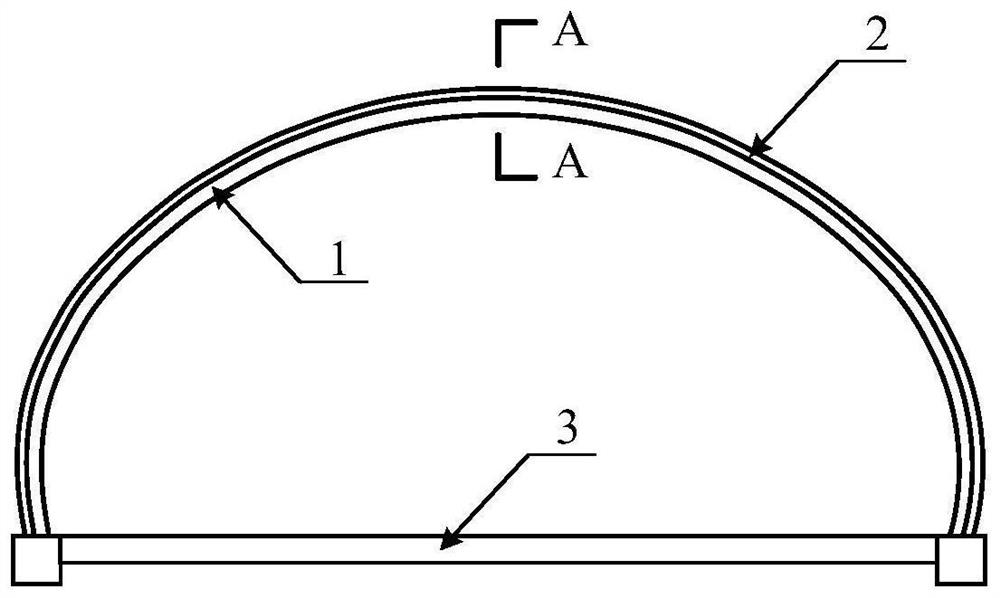

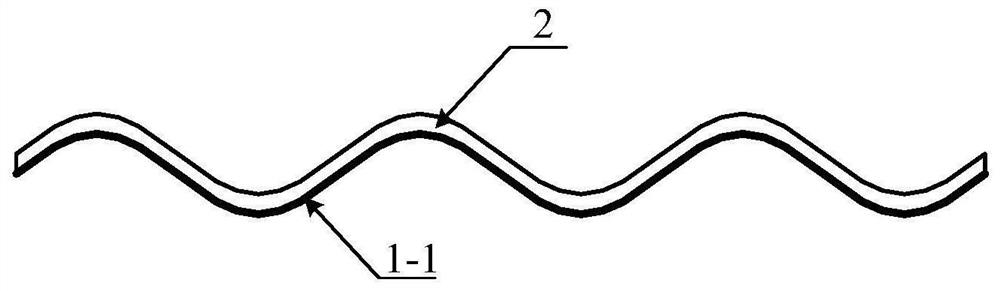

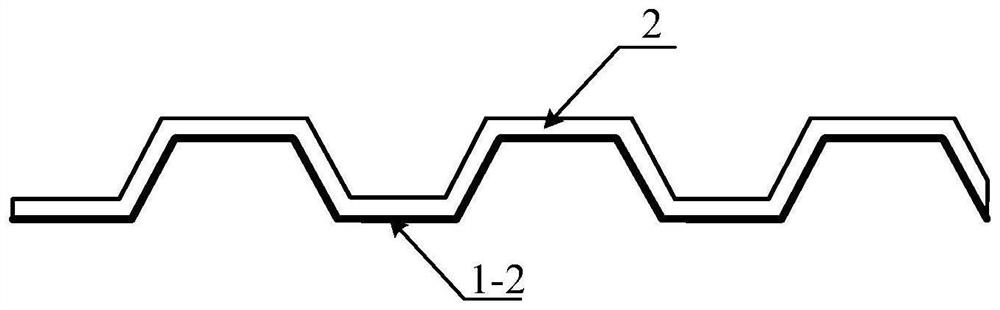

[0029] Such as figure 1 As shown, a comprehensive pipe gallery using sprayed ultra-high toughness cement-based composite materials includes the following components: corrugated steel plate 1, including two forms: sinusoidal corrugated steel plate 1-1, trapezoidal corrugated steel plate 1-2; fiber mesh reinforcement Ultra-high toughness cement-based composite material 2; concrete base 3.

[0030] Such as figure 1 As shown, the comprehensive pipe gallery structure includes corrugated steel plate 1, fiber mesh reinforced ultra-high toughness cement-based composite material 2, and concrete base 3; the corrugated steel plate 1 forms an arched section through cold bending, and the end is supported on the concrete base 3 Above, the fiber mesh reinforced ultra-high toughness cement-based composite material 2 is arranged outside the corrugated steel plate 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com