Efficient sun screen

A high-efficiency, solution-based technology, applied in the direction of medical preparations containing active ingredients, cosmetics, skin care preparations, etc., can solve problems such as blocked hair follicles, questionable safety, and low sunscreen performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

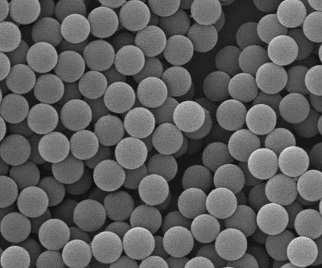

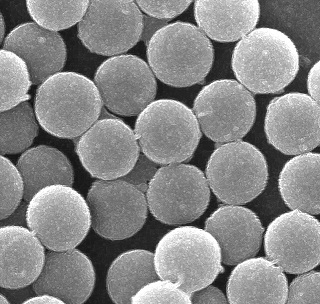

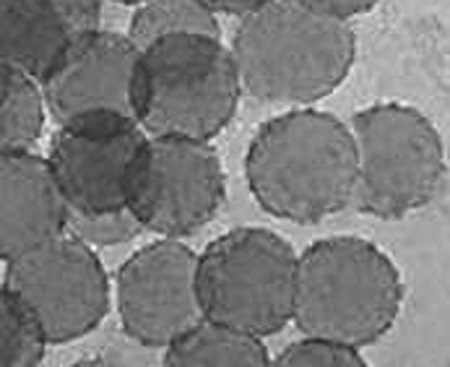

Image

Examples

Embodiment 1

[0045] A high-efficiency sunscreen liquid, characterized in that the sunscreen liquid includes

[0046] Trimethylcyclohexyl salicylate 80mg / g;

[0047] Octocrylene 60mg / g;

[0048] Octyl salicylate 50mg / g;

[0049] Butylmethoxydibenzoylmethane 30mg / g;

[0050] 4-Methylbenzylidene camphor 25mg / g;

[0051] PMMA@ZnO core-shell particles 50mg / g.

[0052] The preparation method of PMMA@ZnO is as follows:

[0053] 1) Add 72mg of initiator azobisisobutyronitrile, 2.5g of dispersant polyvinylpyrrolidone, and 0.79ml of crosslinking agent ethylene glycol dimethacrylate into a solvent of 95vol.% acetonitrile / 5vol.% toluene, fully Disperse to obtain a solution.

[0054] 2) Add 3g of methyl methacrylate and 1.5g of acrylamide to the solution obtained in step 1), slowly pass through N2 protection for 30min, and then rise to the reaction temperature of 85°C. After 4 hours of continuous reaction, the experiment is over, and the product is poured out. Vacuum filtration, tetrahydrofuran ...

Embodiment 2

[0060] A high-efficiency sunscreen liquid, characterized in that the sunscreen liquid includes

[0061] Trimethylcyclohexyl salicylate 80mg / g;

[0062] Octocrylene 60mg / g;

[0063] Octyl salicylate 50mg / g;

[0064] Butylmethoxydibenzoylmethane 30mg / g;

[0065] 4-Methylbenzylidene camphor 25mg / g;

[0066] PMMA@ZnO core-shell particles 55mg / g.

[0067] The preparation method of PMMA@ZnO is as follows:

[0068] 1) Add 72mg of initiator azobisisobutyronitrile, 2.5g of dispersant polyvinylpyrrolidone, and 0.79ml of crosslinking agent ethylene glycol dimethacrylate into a solvent of 95vol.% acetonitrile / 5vol.% toluene, fully Disperse to obtain a solution.

[0069] 2) Add 3g of methyl methacrylate and 1.5g of acrylamide to the solution obtained in step 1), slowly pass through N2 protection for 30min, and then rise to the reaction temperature of 85°C. After 4 hours of continuous reaction, the experiment is over, and the product is poured out. Vacuum filtration, tetrahydrofuran ...

Embodiment 3

[0075] A high-efficiency sunscreen liquid, characterized in that the sunscreen liquid includes

[0076] Trimethylcyclohexyl salicylate 80mg / g;

[0077] Octocrylene 60mg / g;

[0078] Octyl salicylate 50mg / g;

[0079] Butylmethoxydibenzoylmethane 30mg / g;

[0080] 4-Methylbenzylidene camphor 25mg / g;

[0081] PMMA@ZnO core-shell particles 60mg / g.

[0082] The preparation method of PMMA@ZnO is as follows:

[0083] 1) Add 72mg of initiator azobisisobutyronitrile, 2.5g of dispersant polyvinylpyrrolidone, and 0.79ml of crosslinking agent ethylene glycol dimethacrylate into a solvent of 95vol.% acetonitrile / 5vol.% toluene, fully Disperse to obtain a solution.

[0084] 2) Add 3g of methyl methacrylate and 1.5g of acrylamide to the solution obtained in step 1), slowly pass through N2 protection for 30min, and then rise to the reaction temperature of 85°C. After 4 hours of continuous reaction, the experiment is over, and the product is poured out. Vacuum filtration, tetrahydrofuran ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com