Abrasive flow finishing equipment for batch machining of gear parts

A technology for batch processing and parts, applied in the field of abrasive streamer finishing equipment, which can solve the problems of insufficient production capacity and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

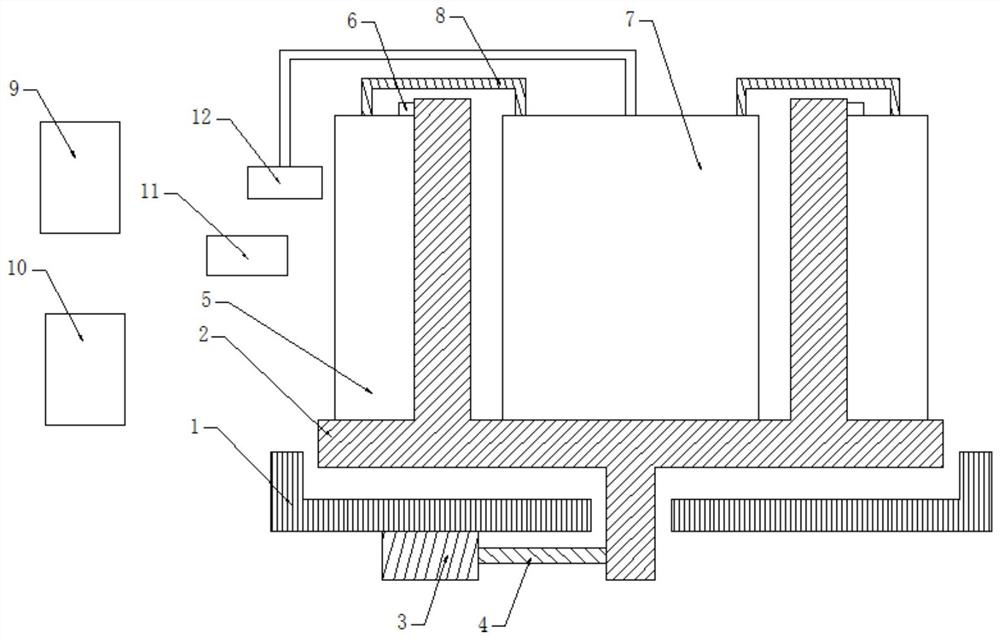

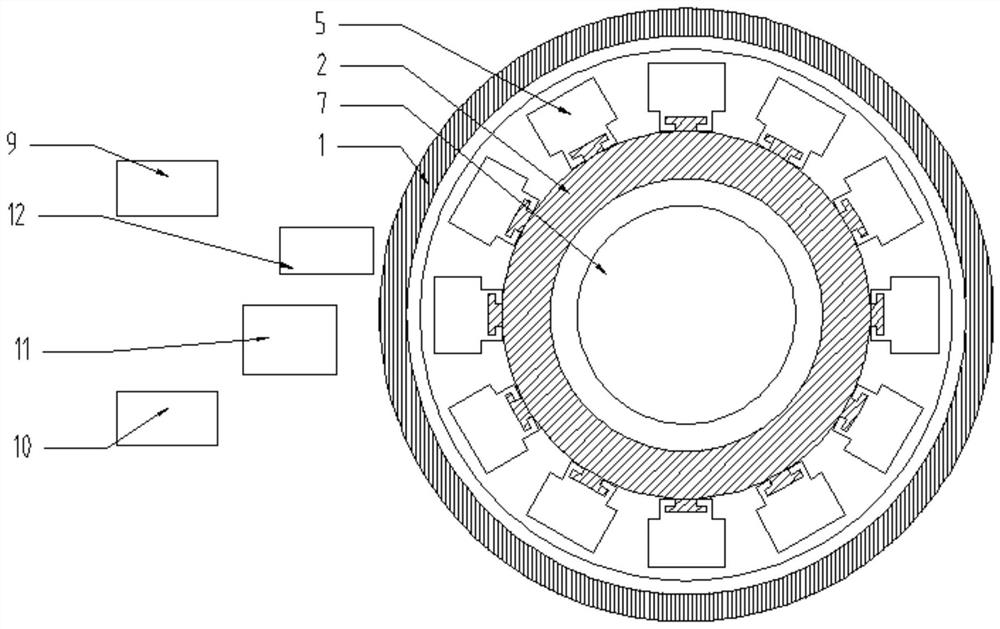

[0028] as attached figure 1 As shown, the present invention provides abrasive flow finishing equipment for batch processing of gear parts, including a frame 1, a rotary mechanism 2, an active power source 3, a main driving device 4, a finishing unit 5, a locking mechanism 6, and an abrasive material bin 7. Abrasive conveying mechanism 8, parts loading and unloading manipulator 9, pressure blowing chamber 10, roughness on-line detection device 11 and abrasive recycling device 12.

[0029] The main power source 3 is installed under the frame 1, and the slewing mechanism 2 is installed above the frame 1. The main power source 3 drives the rotary spindle at the lower end of the slewing mechanism 2 through the main drive device 4, so that the slewing mechanism 2 maintains a certain speed for circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com