Online monitoring device and method for mechanical acceleration clarification tank

A technology for accelerating clarification and monitoring devices, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the lagging operation control of clarification tanks and the inability to control the amount of dosing in time and the amount of sludge discharged, the water quality of the effluent from the clarification tank is not up to standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

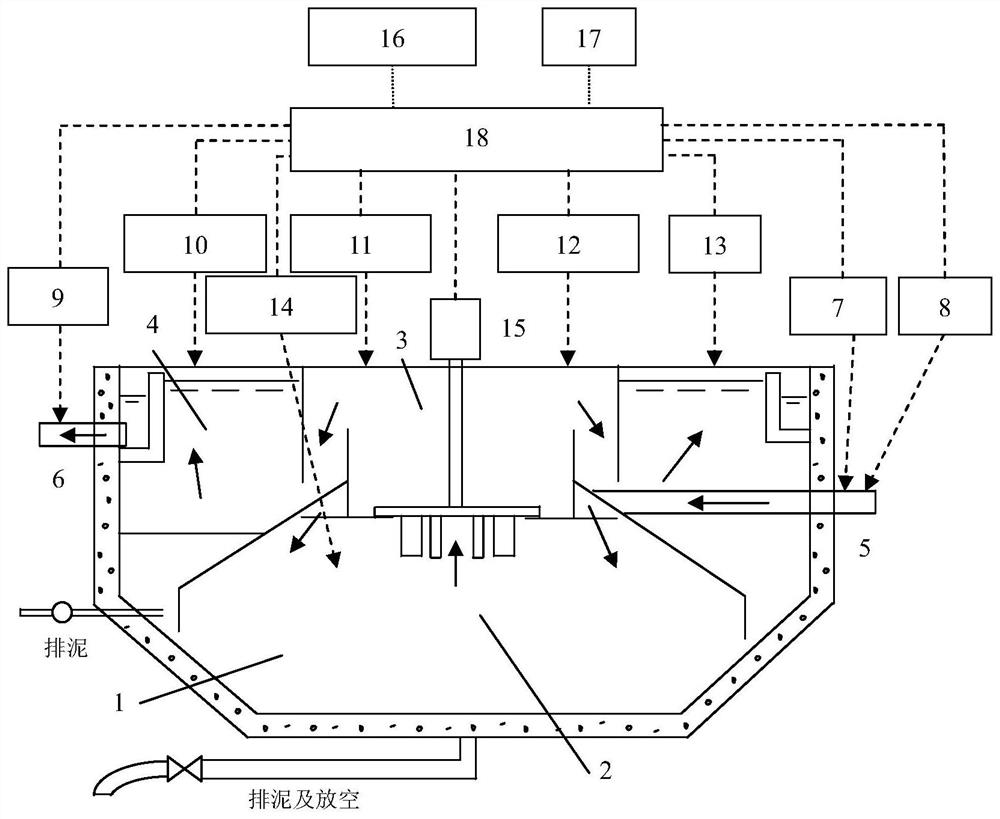

[0036] Such as figure 1 As shown, the present invention is an on-line monitoring device for a mechanically accelerated clarifier. Various detection equipment of the device are arranged in key parts of each reaction area and clear water area of the clarifier to realize online detection and monitoring of the operating parameters of the clarifier; Real-time operation parameters are compared with empirical data to guide operation adjustment and control, and improve the effluent water quality of the coagulation and clarification system; the device includes a mechanical acceleration clarification tank 1, and its internal primary mixing and reaction zone 2, secondary mixing and reaction zone 3. Clean water area 4, inlet pipeline 5, outlet pipeline 6 and mixer 15; the mechanical acceleration clarifier 1 is circular, and its interior is divided into primary mixing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com