Antibacterial melt-blown polypropylene material and preparation method thereof

A technology of polypropylene material and polypropylene powder, which is applied in the field of antibacterial melt-blown polypropylene material and its preparation, and can solve the rare and ineffective sterilization problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

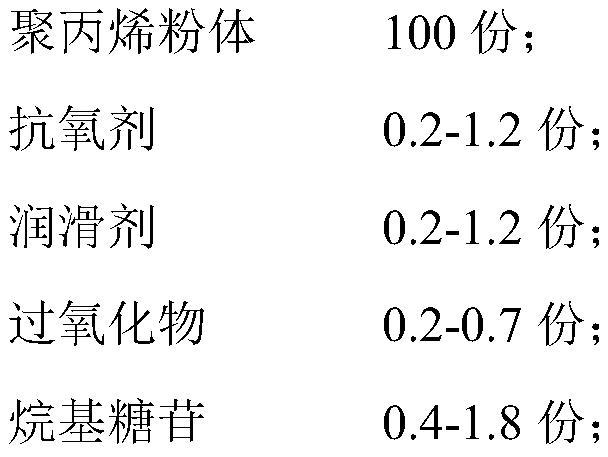

[0069] An antibacterial melt-blown grade polypropylene material is prepared from the following components by weight:

[0070]

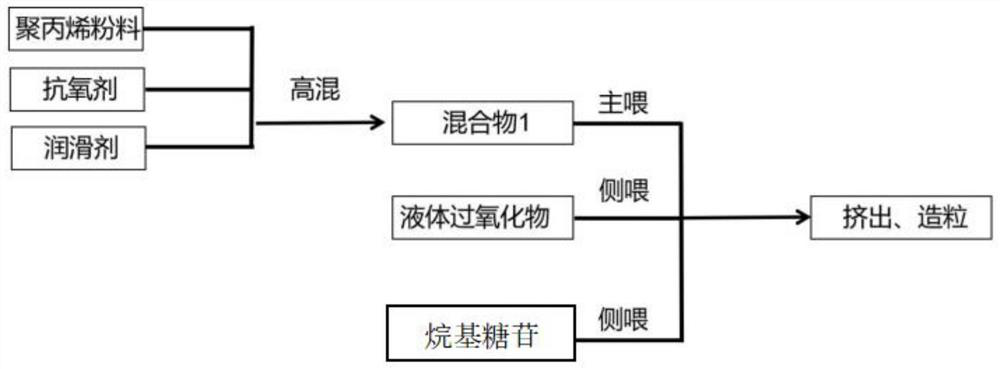

[0071] The preparation method of the antibacterial melt-blown grade polypropylene material of the present embodiment comprises the following steps:

[0072] 1) The polypropylene powder, antioxidant, and lubricant are weighed according to the parts by weight of each raw material component, and mixed evenly with a high-speed mixer, and the speed of the high-speed mixer is 700 rpm.

[0073] 2) Add the mixed material mixed in step 1) with a high-speed mixer into the parallel twin-screw extruder through the main feeder, and in the third zone sideways and the seventh zone of the parallel twin-screw extruder (thirteen zones in total) Liquid peroxide and alkyl glucoside are added sideways by liquid pump for reactive melt extrusion and granulation to obtain granular antibacterial melt-blown polypropylene material. The process parameters are as follows: the...

Embodiment 2

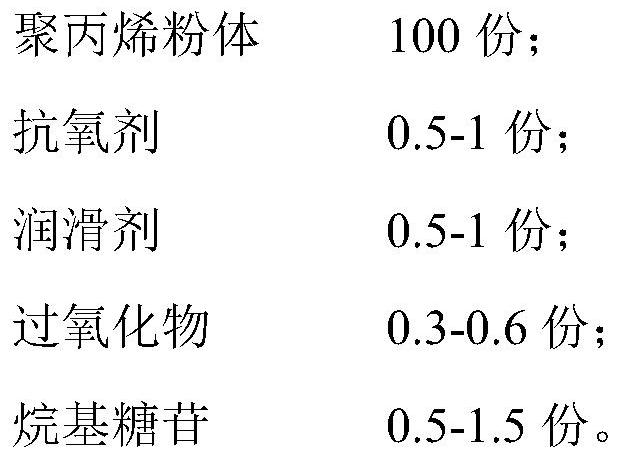

[0075] An antibacterial melt-blown grade polypropylene material is prepared from the following components by weight:

[0076]

[0077]

[0078] The preparation method of the antibacterial melt-blown grade polypropylene material of the present embodiment comprises the following steps:

[0079] 1) The polypropylene powder, antioxidant, and lubricant are weighed according to the parts by weight of each raw material component, and mixed evenly with a high-speed mixer, and the speed of the high-speed mixer is 700 rpm.

[0080] 2) Add the mixed material mixed in step 1) with a high-speed mixer into the parallel twin-screw extruder through the main feeder, and in the third zone sideways and the seventh zone of the parallel twin-screw extruder (thirteen zones in total) Liquid peroxide and alkyl glucoside are added sideways by liquid pump for reactive melt extrusion and granulation to obtain granular antibacterial melt-blown polypropylene material. The process parameters are as ...

Embodiment 3

[0082] An antibacterial melt-blown grade polypropylene material is prepared from the following components by weight:

[0083]

[0084] The preparation method of the antibacterial melt-blown grade polypropylene material of the present embodiment comprises the following steps:

[0085] 1) The polypropylene powder, antioxidant, and lubricant are weighed according to the parts by weight of each raw material component, and mixed evenly with a high-speed mixer, and the speed of the high-speed mixer is 700 rpm.

[0086] 2) Add the mixed material mixed in step 1) with a high-speed mixer into the parallel twin-screw extruder through the main feeder, and in the third zone sideways and the seventh zone of the parallel twin-screw extruder (thirteen zones in total) Liquid peroxide and alkyl glucoside are added sideways by liquid pump for reactive melt extrusion and granulation to obtain granular antibacterial melt-blown polypropylene material. The process parameters are as follows: the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com