Low-migration ultraviolet curing ink and preparation method thereof

A UV light, low-migration technology, applied in ink, household utensils, applications, etc., can solve migration and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

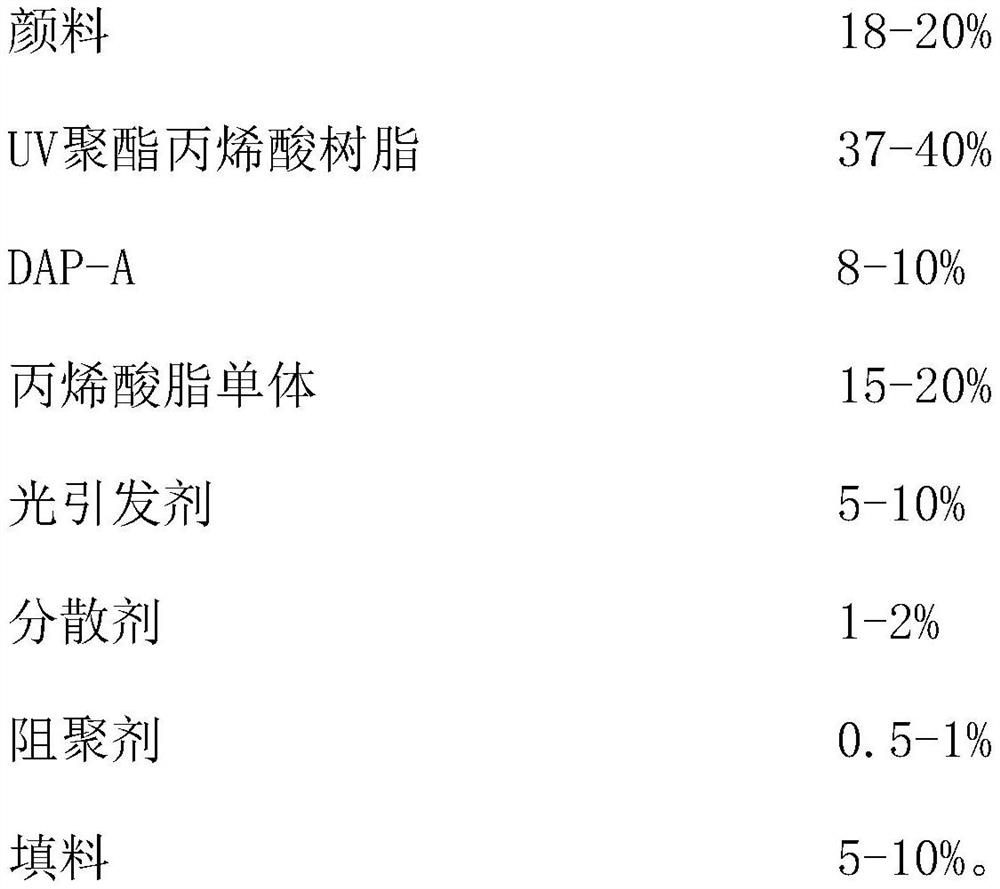

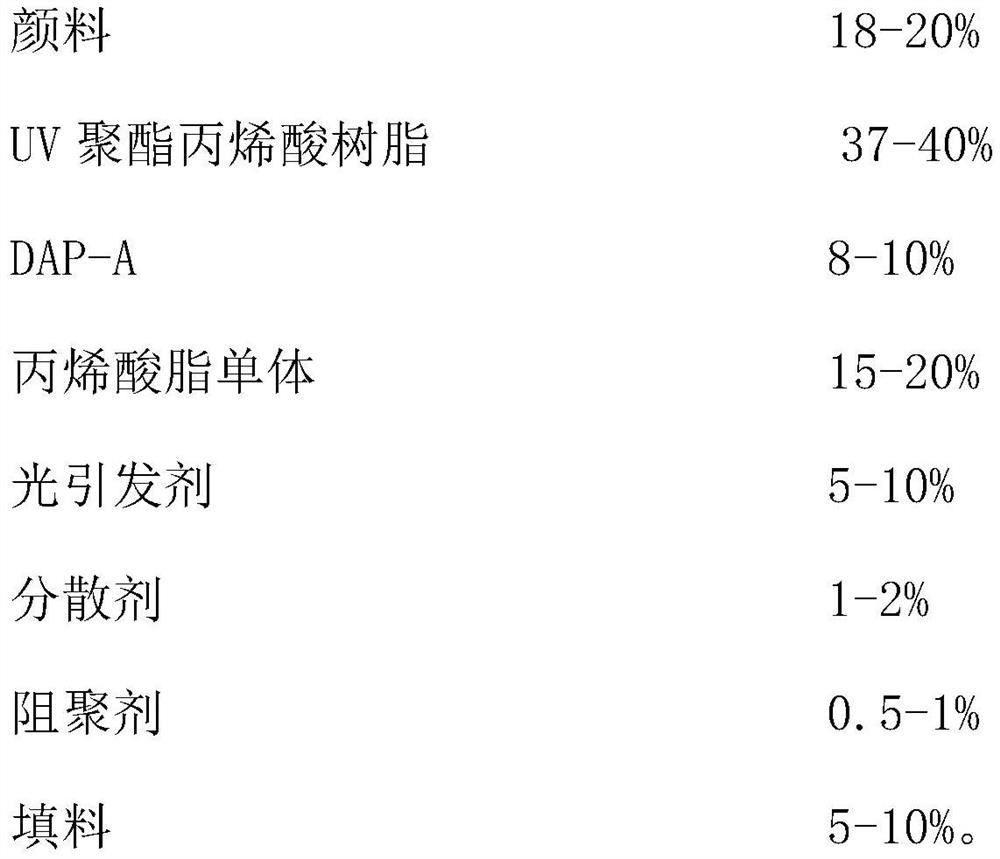

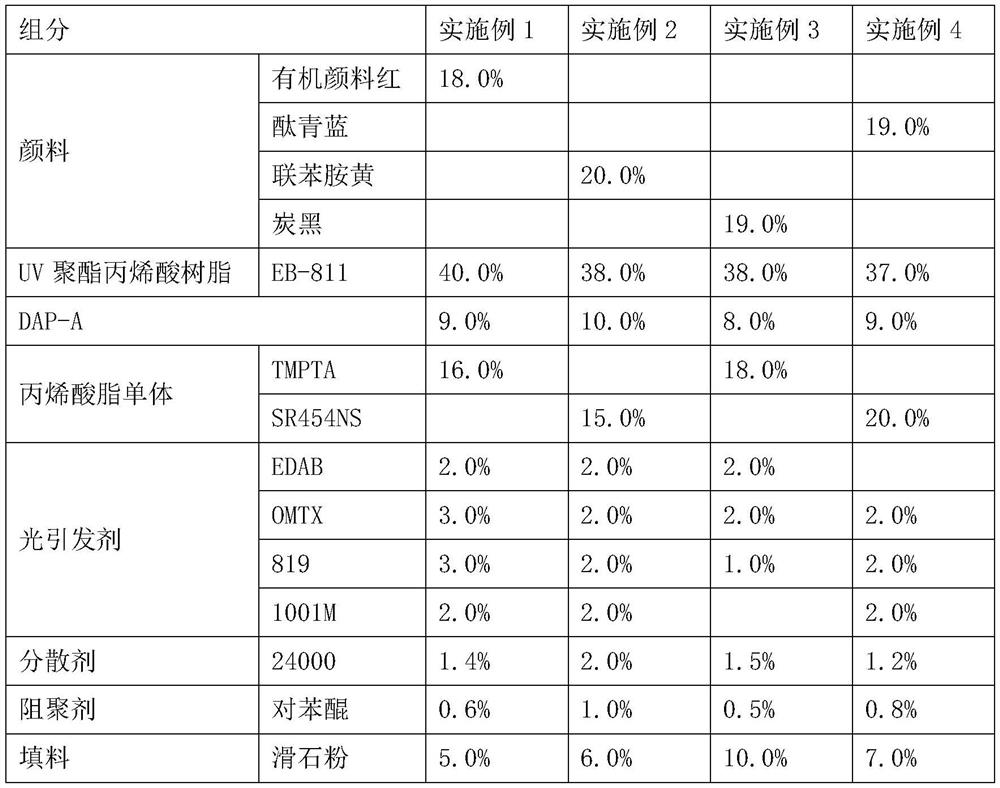

[0024] Below in conjunction with specific embodiment 1-4 illustrate the concrete technical scheme of the present invention:

[0025] The offset printing ink of embodiment 1-4 adopts following preparation method, comprises the following steps:

[0026] Prepare the raw materials according to the weight percentage in Table 1. First, mix the UV polyester acrylic resin, DAP-A, acrylate monomer, polymerization inhibitor, dispersant, and photoinitiator evenly, and disperse them with a high-speed mixer until they are completely dissolved, and then add the pigment , Filler, fully stirred until preliminary dispersion, and then fully ground on a three-roller machine until the ink has a fineness of less than 10 microns.

[0027] Table 1: The weight ratio of ink in Examples 1-4

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com