Method for improving performance of phosphate fire-resistant hydraulic oil

A phosphate ester and hydraulic oil technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of high cost, low volume resistivity and self-ignition point, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

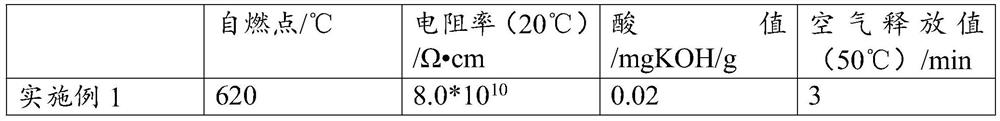

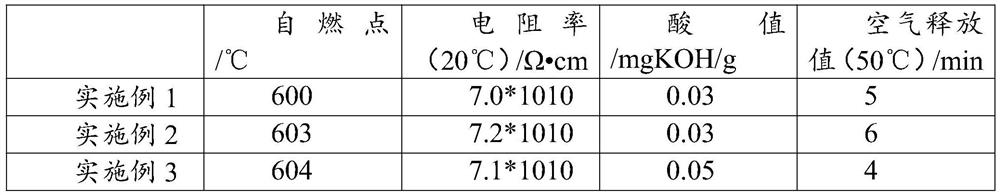

Embodiment 1

[0028] Method for increasing phosphate anti-combustion hydraulic resistance, including the following steps:

[0029] S1: Add magnesium aluminum hydrazine to the phosphate base oil, stirred at 200 ° C, stirring 10 h, then filtered, to obtain magnesium aluminum water talc and improved phosphate base oil; control magnesium aluminum water talc and phosphate The mass ratio of the base oil is 20: 100;

[0030] S2: In the improved phosphate base oil, the antioxidant, the acidic agent, the antifugger, and the dye are mixed, i.e., to obtain phosphate anti-ignifier pressure.

[0031] S3: Magnesium-aluminum water talc is washed, filtered, dried, baked, recovered.

[0032] Magnesium-aluminum talc is a variety of carbonate type, sulfate type, nitrate type or chloride type; the calcination regeneration of magnesium aluminum talc is 600 ° C.

[0033] Viscosity Index Improved is a polyacrylate derivative; such as polymethyl methacrylate, polymethyl methacrylate, styrene-butadiene copolymer, and p...

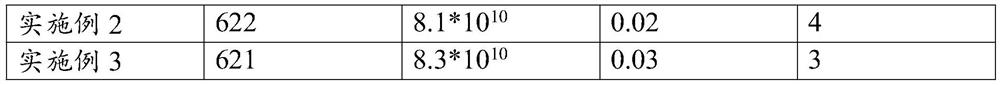

Embodiment 2

[0047] Method for increasing phosphate anti-combustion hydraulic resistance, including the following steps:

[0048] S1: Add magnesium aluminum water talc to the phosphate base oil, stirred at 150 ° C, stir-adsorption 5 h, then filtrate separation, to obtain magnesium aluminum talc and improve phosphate base oil; control magnesium aluminum talc and phosphate foundation The quality ratio of oil is 10: 100;

[0049] S2: Mixing the viscosity index modifier, antioxidant, acidic acid, antifuguant and dye is added to improve the phosphate base oil, i.e., obtaining phosphate type antibiotic pressure.

[0050] S3: Magnesium-aluminum talc is washed, filtered, dried, and calcined, recovered.

[0051] Magnesium-aluminum talc is a variety of carbonate type, sulfate type, nitrate type or chloride ion type; magnesium-aluminum talc, the firing regeneration temperature of 400 ° C.

[0052] The viscosity index modifier is a polyacrylate derivative; the polyacrylate derivative is polymethyl methacr...

Embodiment 3

[0063] Method for improving phosphate base oil performance, including the following steps:

[0064] S1: Add magnesium aluminum water talc to the phosphate base oil, stirred at 200 ° C, stir the adsorption of 10 h, then filtrate separation, to obtain magnesium aluminum water talc and improve phosphate base oil; control magnesium aluminum water talc and phosphate foundation The mass ratio of oil is 20: 100;

[0065] S2: Mixing the viscosity index improvement agent, antioxidant, acidic acid, antifuguant and dye is added to the improved phosphate base oil, i.e., to obtain phosphate anti-inefficiencies;

[0066] S3: Magnesium-aluminum talc is washed, filtered, dried, and calcined, recovered.

[0067] Magnesium-aluminum talc is a variety of carbonate type, sulfate type, nitrate type or chloride type; the calcination regeneration of magnesium aluminum talc is 600 ° C.

[0068] The viscosity index modifier is a polyacrylate derivative; the polyacrylate derivative is polymethyl methacrylat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com