Surface modification vertical device and method based on ultrasonic rolling technology

A surface modification and ultrasonic rolling technology, applied in the field of surface modification vertical devices, can solve the problems of difficult to achieve surface modification treatment of flat parts, machine rigidity and precision damage, and small depth of plastic deformation layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

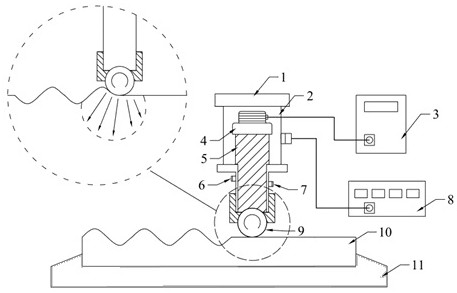

[0030] Embodiment 1: as Figure 1~2 As shown, in this embodiment, a surface modification vertical device based on ultrasonic rolling technology is provided, including a vertical machining center machine tool, an ultrasonic actuator 2, an ultrasonic generator 3 and an air compressor 8, and the ultrasonic The generator is connected to the ultrasonic actuator through the cable to provide energy for the processing system, and the air compressor is connected to the ultrasonic actuator through the pipeline to provide the initial static pressure and can be adjusted through the pressure gauge;

[0031] The ultrasonic actuator includes an ultrasonic transducer 4, a horn 5 and a tool head 9 installed on the main shaft 1 of the vertical machining center from top to bottom.

[0032] The above-mentioned ultrasonic transducer is used to convert the high-frequency AC signal into mechanical vibration of the same frequency; the above-mentioned horn is used to amplify the mechanical vibration o...

Embodiment 2

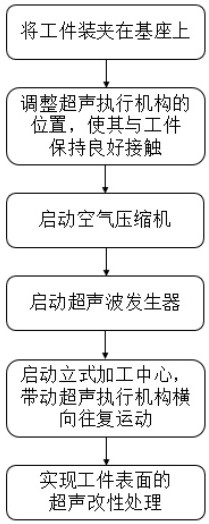

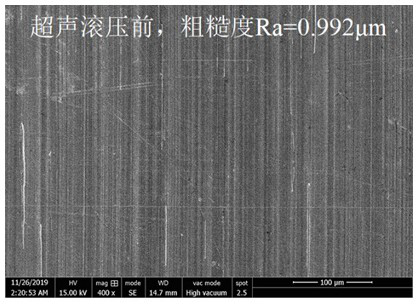

[0048] Embodiment 2: Cut a section of metal sample with the method of wire cutting, observe its surface topography under electron microscope and measure surface roughness Ra, its surface microscopic topography is as follows image 3 As shown, before ultrasonic rolling treatment, the workpiece surface has dense processing marks, many defects, extremely uneven, and high surface roughness; after ultrasonic rolling treatment, such as Figure 4 As shown, the surface of the workpiece becomes continuous, flat and uniform, and the surface roughness is greatly reduced. At the same time, if Figure 5 As shown, the metallographic structure of its surface is observed under an optical microscope, and its microstructure; as Image 6 As shown, the surface structure of the metal sample after the ultrasonic rolling treatment is significantly refined, the original coarse grains are transformed into tiny particles, the originally clearly visible grain boundaries are destroyed or even hidden, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com