Preparation method of high-conductivity deformed Cu-Fe in-situ composite material

An in-situ composite material, high conductivity technology, applied in the field of non-ferrous metal material preparation, can solve problems such as difficulty in effectively promoting the precipitation of solid solution atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

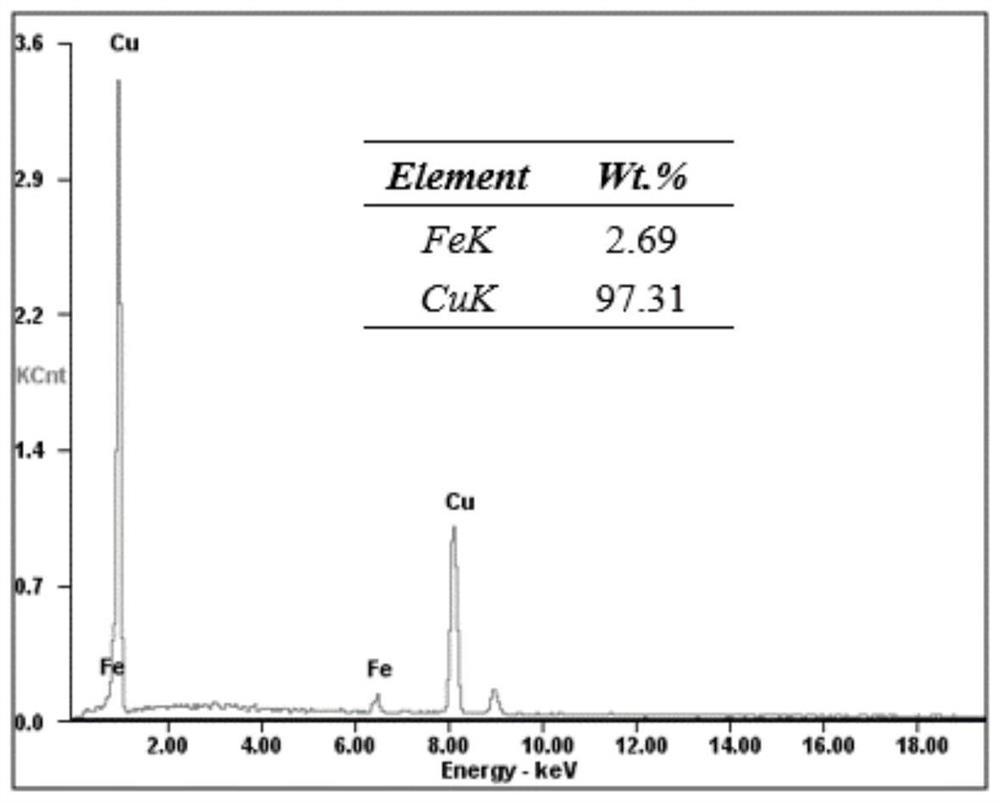

Embodiment 1

[0028] (1) take iron powder 8%, graphene 0.8% and copper powder 3% respectively by mass percentage, adopt ball material mass ratio to be 15, ball milling time is 2h (first iron powder and graphene are carried out ball milling 1.5h, after Add copper powder and then ball mill for 0.5h), the speed is 250r / min, and the mixed powder is subjected to liquid nitrogen low-temperature ball milling.

[0029] (2) Weigh the remaining copper block according to the mass percentage, carry out medium frequency induction melting, after the melt is formed and stand for 2-3 minutes, add 0.6% wetting agent magnesium and ball milling mixed powder to the copper melt, and cast it into graphite ene Cu-Fe alloy rods.

[0030] (3) Heat the graphene Cu-Fe alloy rod at 960°C for 4 hours, then water quench it, and then hot-roll it at 850°C. The temperature of the hot-rolling process is controlled above 780°C, and the hot-rolled rod is cold-drawn for multiple passes at room temperature to obtain Graphene-d...

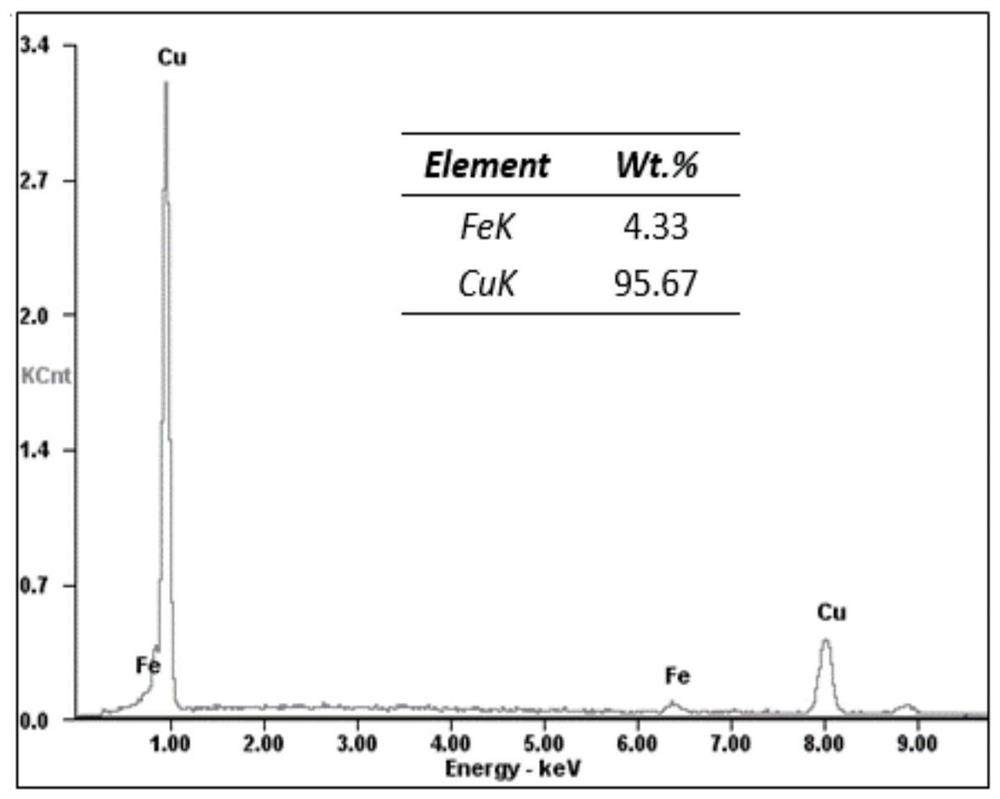

Embodiment 2

[0034] (1) Take iron powder 10%, graphene 1% and copper powder 3% by mass percentage respectively, adopt the mass ratio of ball material to be 20, and the ball milling time is 2h (first iron powder and graphene are carried out ball milling 1.5h, after Add copper powder and then ball mill for 0.5h), the speed is 300r / min, and the mixed powder is subjected to liquid nitrogen low-temperature ball milling.

[0035] (2) Weigh the remaining copper block according to the mass percentage, and carry out medium frequency induction melting. After the melt is formed and allowed to stand for 2-3 minutes, add 0.7% wetting agent magnesium and ball milling mixed powder to the copper melt, and cast it into graphite ene Cu-Fe alloy rods.

[0036] (3) Heat the graphene Cu-Fe alloy rod at 1000°C for 4 hours, then water quench it, and then hot-roll it at 850°C. The temperature of the hot-rolling process is controlled above 780°C. Graphene-deformed Cu-Fe in-situ composites with a cold deformation ...

Embodiment 3

[0040] (1) Take iron powder 12%, graphene 1.2% and copper powder 4% respectively by mass percentage, adopt ball material mass ratio to be 20, ball milling time is 3h (first iron powder and graphene are carried out ball milling 2h, then add The copper powder is then ball milled for 1h), and the mixed powder is subjected to liquid nitrogen low-temperature ball milling in a process with a rotating speed of 300r / min.

[0041] (2) Weigh the remaining copper block according to the mass percentage, carry out medium frequency induction melting, after the melt is formed and stand for 2-3 minutes, add 0.8% wetting agent magnesium and ball milling mixed powder to the copper melt, and cast it into graphite ene Cu-Fe alloy rods.

[0042] (3) Heat the graphene Cu-Fe alloy rod at 1040°C for 6h, then water quench it, and then hot-roll it at 850°C. The temperature of the hot-rolling process is controlled above 780°C, and the hot-rolled rod is cold-drawn multiple times at room temperature to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com