Preparation and application of photonic crystal material with responsive invisible pattern

A photonic crystal and responsive technology, which is applied in the field of nanomaterials and functional polymer materials, can solve the problems of poor mechanical properties of patterns, swelling of responsiveness of pattern areas or poor tensile properties, and inability to develop colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

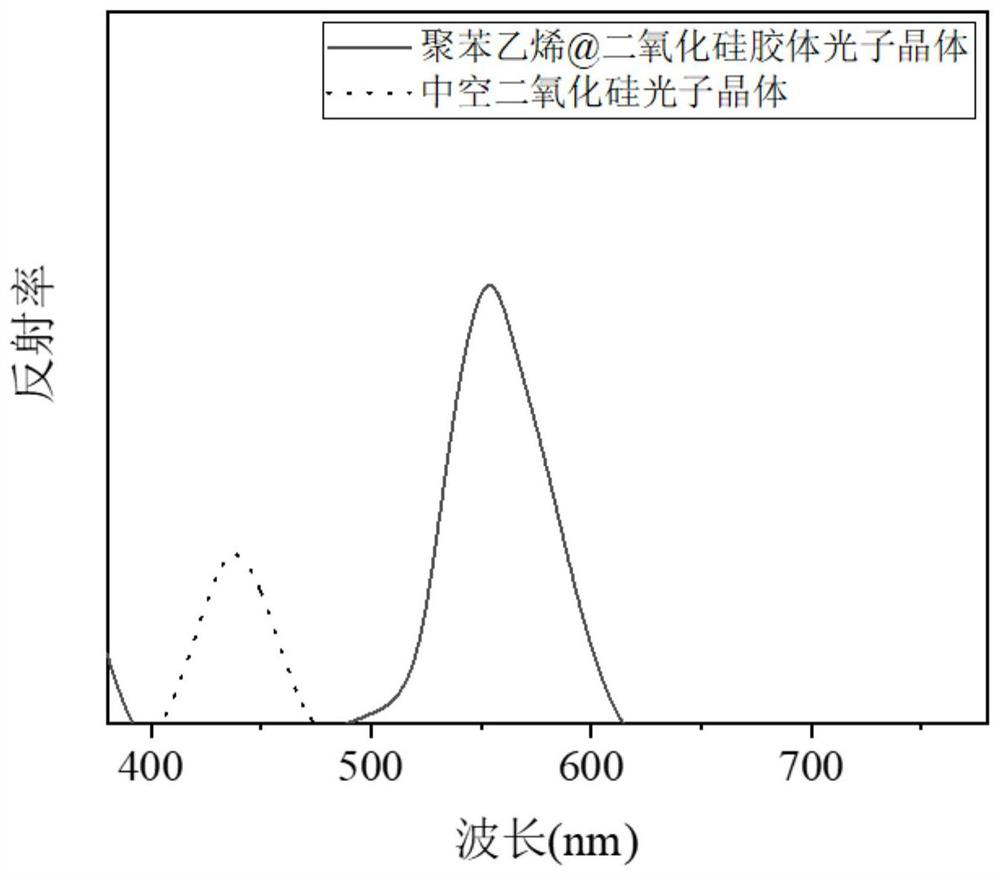

[0052] Embodiment 1 Preparation of hollow silica photonic crystal

[0053] (1) Preparation of polystyrene@silica colloid:

[0054] Add 0.6g styrene, 0.9g polyvinylpyrrolidone, 0.13g 2,2'-azobisisobutylamidine dihydrochloride and 300g water into a 500mL three-necked flask, and react at 70°C for 24h. Purified by centrifugal washing to finally obtain polystyrene microspheres with a diameter of 205 nm;

[0055] Next, polystyrene@silica microspheres were prepared: 0.6 g of polystyrene microspheres were dispersed in 120 mL of ethanol. Then 3.1 mL of tetraethylorthosilicate and 8 mL of aqueous ammonia were added to the diluted dispersion under magnetic stirring. Reaction at 50°C for 3h. Purified by centrifugal washing, the final polystyrene@silica colloid with a diameter of 245 nm was obtained.

[0056] Finally, by vertically depositing polystyrene@silica colloidal photonic crystals on the substrate: place the clean substrate vertically in a polystyrene@silica colloidal suspensio...

Embodiment 2

[0062] Example 2 Hollow silica photonic crystal material with responsive invisible pattern

[0063] (1) Preparation of olefin-modified hollow silica photonic crystals:

[0064] Immerse the hollow silica photonic crystal in 30 mL of absolute ethanol. Subsequently, 1.5 mL of γ-methacryloxypropyltrimethoxysilane and 3.0 mL of ammonia water were added to the above solution at a stirring speed of 1100 rpm. The reaction was carried out under continuous stirring at room temperature for 6 h. Then the resulting film was completely washed with ethanol to obtain olefin-modified hollow silica photonic crystals.

[0065] It should be noted that, under the same conditions, when the amount of γ-methacryloxypropyltrimethoxysilane was replaced by 3.0mL, 4.5mL and 6.0mL, the olefin-modified hollow bismuth Silica photonic crystals; under the same conditions, when the amount of ammonia added was replaced by 1.5mL, 4.5mL and 6.0mL, olefin-modified hollow silica photonic crystals could be succes...

Embodiment 3

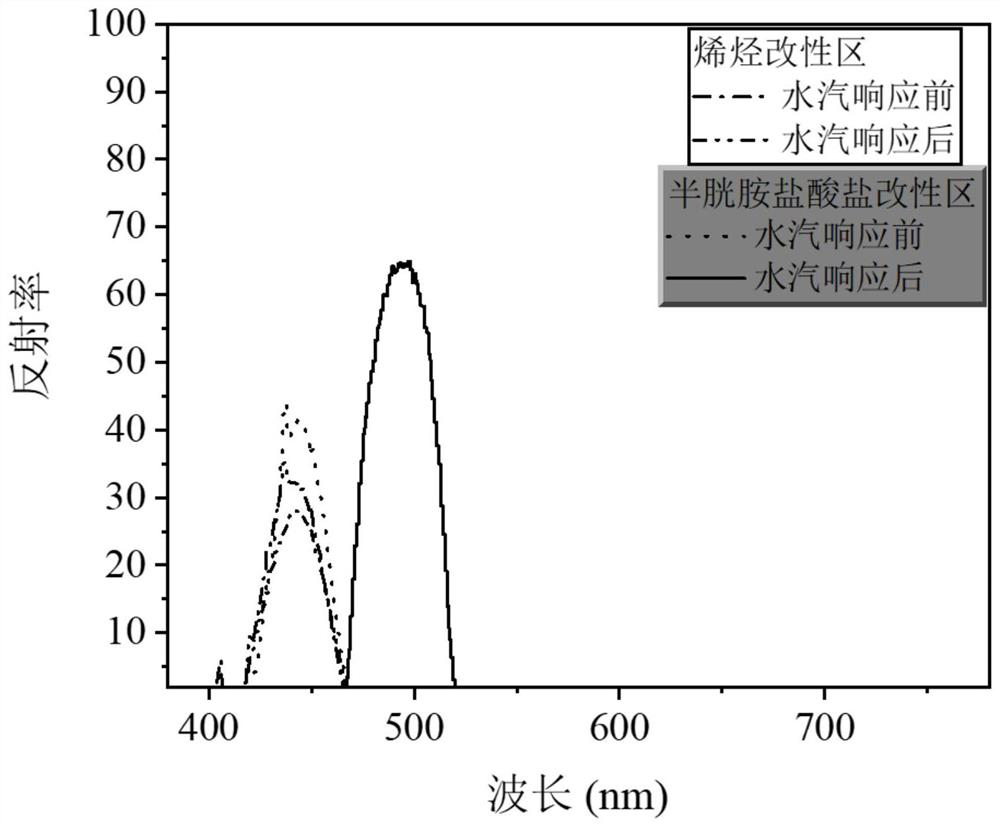

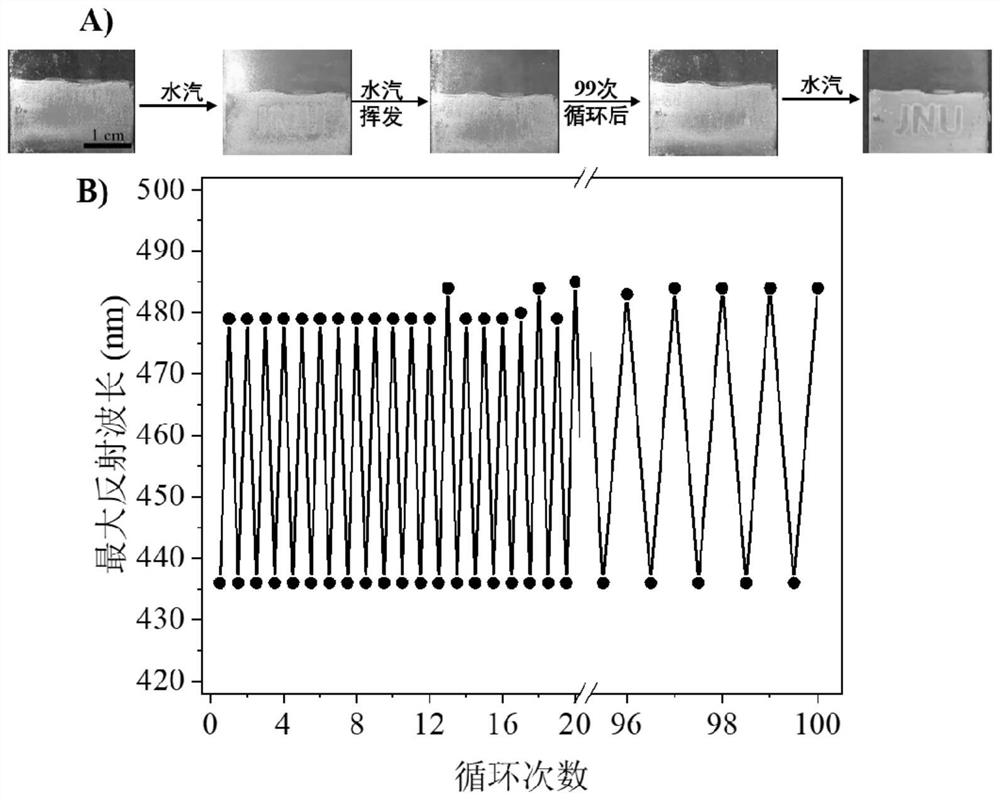

[0069] Embodiment 3 Water vapor appearance detection of responsive invisible pattern

[0070] In the obtained thiol-modified hollow silica photonic crystal, the olefin modification area (background area) and the cysteamine hydrochloride modification area (pattern area) that have not introduced mercapto groups in the obtained mercapto-modified hollow silica photonic crystal) are placed in a dynamic environment where the relative humidity is 80% RH. The reflectance spectrum was measured under humidity. After 1 second, there was no obvious change in the reflectance spectrum of the background area, but the maximum reflection wavelength of the pattern area was significantly red-shifted (51nm), such as figure 2 . It can be seen that the invisible pattern of the modified hollow silica photonic crystal has water vapor responsiveness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com