High-strength multi-layer kraft liner board and preparation method thereof

A kraft box, high-strength technology, applied in the field of papermaking, can solve the problem of reducing the amount of wood pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

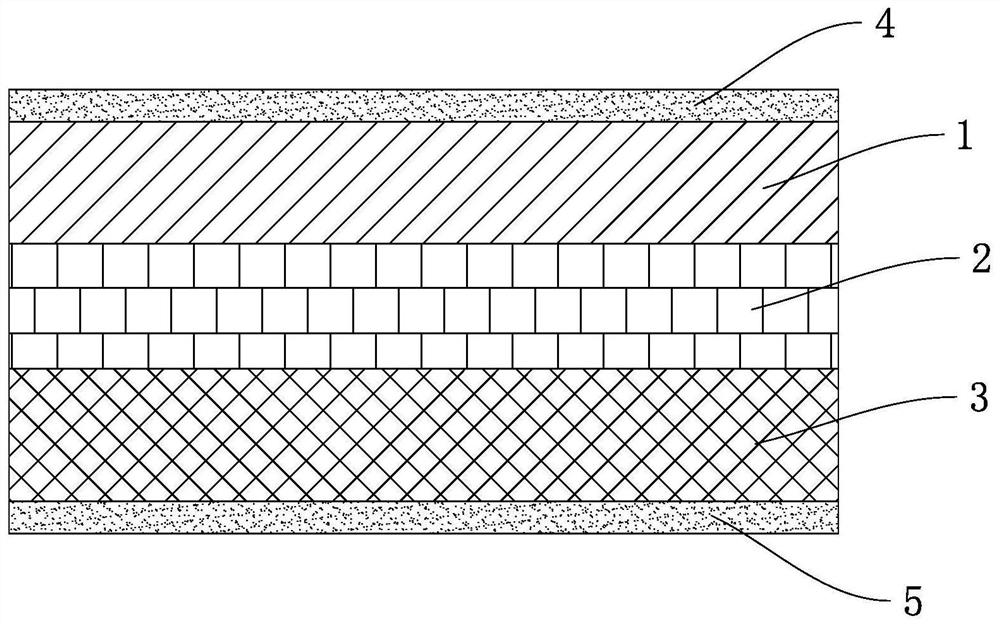

[0034] This embodiment provides a method for preparing high-strength multi-layer kraft liner board, such as figure 1 shown, including the following steps:

[0035] Step 1: Use waste paper as raw material, pulp it with a hydropulper, remove slag and coarse sieve, enter the fiber grading sieve, and sieve to obtain long-fiber pulp with a fiber length of 2.0-3.5mm, and the fiber length is 1.1-2.0mm medium fiber pulp and 0.8-1.1mm short fiber pulp;

[0036] Step 2: Mix the long-fiber pulp and the short-fiber pulp at a ratio of 80:20 by mass and number, add a reinforcing agent and a water-resistant agent in the pulp, and mix evenly to obtain the pulp for the surface layer. The short-fiber pulp and the medium After the fiber pulp is uniformly mixed in a ratio of 80:20 in parts by mass, the pulp for the core layer is obtained. After the medium fiber pulp and short fiber pulp are uniformly mixed in a ratio of 80:20 in parts by mass, the pulp for the bottom layer is obtained. , wherei...

Embodiment 2

[0042] This embodiment provides a method for preparing high-strength multi-layer kraft liner board, such as figure 1 shown, including the following steps:

[0043] Step 1: Use waste paper as raw material, pulp it with a hydropulper, remove slag and coarse sieve, enter the fiber grading sieve, and sieve to obtain long-fiber pulp with a fiber length of 2.0-3.5mm, and the fiber length is 1.1-2.0mm medium fiber pulp and 0.8-1.1mm short fiber pulp;

[0044] Step 2: Mix long-fiber pulp and short-fiber pulp at a ratio of 90:10 by mass and number, add a reinforcing agent and a water-resistant agent in the pulp, and mix evenly to obtain pulp for the surface layer. Mix short-fiber pulp and medium After the fiber pulp is uniformly mixed at a ratio of 85:15 in parts by mass, the pulp for the core layer is obtained. After the medium fiber pulp and short fiber pulp are uniformly mixed in a ratio of 85:15 in parts by mass, the pulp for the bottom layer is obtained. , wherein, the addition ...

Embodiment 3

[0050] This embodiment provides a method for preparing high-strength multi-layer kraft liner board, such as figure 1 shown, including the following steps:

[0051] Step 1: Use waste paper as raw material, pulp it with a hydropulper, remove slag and coarse sieve, enter the fiber grading sieve, and sieve to obtain long-fiber pulp with a fiber length of 2.0-3.5mm, and the fiber length is 1.1-2.0mm medium fiber pulp and 0.8-1.1mm short fiber pulp;

[0052] Step 2: Mix long-fiber pulp and short-fiber pulp at a ratio of 85:15 by mass and number, add a reinforcing agent and a water-resistant agent in the pulp, and mix evenly to obtain pulp for the surface layer. Mix short-fiber pulp and medium After the fiber pulp is uniformly mixed at a ratio of 83:17 in parts by mass, the pulp for the core layer is obtained. After the medium fiber pulp and short fiber pulp are uniformly mixed in a ratio of 82:18 in parts by mass, the pulp for the bottom layer is obtained. , wherein, the addition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com