High-density high-energy emulsion explosive and preparation method thereof

An emulsion explosive, high-energy technology, used in explosives, non-explosive/non-thermal components, offensive equipment, etc., can solve the problems of difficult fixing, difficult detonation, difficult installation, etc., to achieve good plasticity, improve mass density, and explosive performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

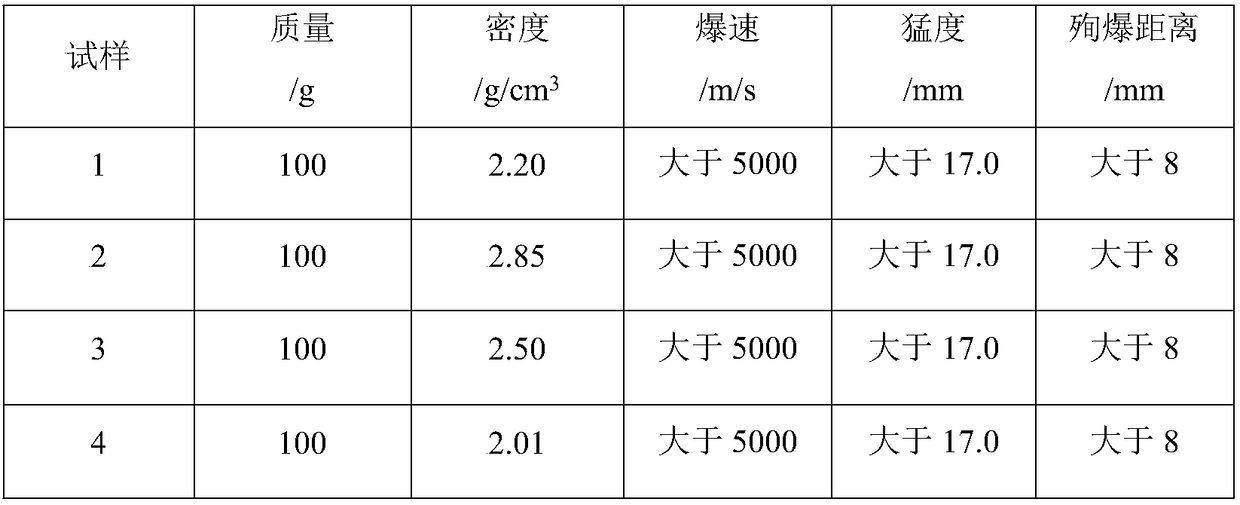

Embodiment 1

[0020] Example 1, take 1 kg of ammonium nitrate, 0.5 kg of ammonium perchlorate, 1 kg of cerium nitrate, 0.7 kg of thiourea, and 2-3 kg of water, and dissolve them completely at a controlled temperature of 100-120° C. to prepare an aqueous solution. Then take 0.3 kg of PCE, 0.2 kg of Span80, 0.4 kg of engine oil, and 0.3 kg of paraffin, and heat it to 110-120°C to make an oil phase solution. Then add the water phase solution and the oil phase solution into the emulsification tank, and at the same time add 0.15-0.25 kg of emulsifier and mix evenly, and finally emulsify to form a viscous emulsified explosive matrix, and finally add 0.2-0.5 kg to meet different engineering needs sensitizer to obtain high-density and high-energy emulsion explosives.

Embodiment 2

[0021] Embodiment 2, take 1 kilogram of ammonium nitrate, 0.8 kilogram of ammonium perchlorate, 1 kilogram of lead nitrate, 0.5 kilogram of urea, 3-4 kilogram of water, control temperature 110-130 ℃ to dissolve completely, make aqueous phase solution. Then take 0.3 kg of Span80, 0.4 kg of T155, 0.3 kg of engine oil, and 0.4 kg of composite wax, and heat it to 110-120°C to make a uniform oil phase solution. Finally, add the water phase solution and the oil phase solution into the emulsification tank, and at the same time add 0.15-0.25 kg of emulsifier and mix evenly, and finally emulsify to form a viscous emulsion explosive matrix. Finally, add 0.4-0.7 kg to meet different engineering needs Additives to obtain high-density and high-energy emulsion explosives.

Embodiment 3

[0022] Embodiment 3, take 1 kilogram of ammonium nitrate, 0.6 kilogram of ammonium perchlorate, 1 kilogram of barium nitrate, 3-4 kilograms of water, 0.8 kilogram of thiourea, control temperature 110-130 ℃ to dissolve completely, make aqueous phase solution. Then take 0.6 kg of PCE, 0.3 kg of T155, 0.4 kg of waste oil, and 0.4 kg of composite wax, and heat it to 110-120°C to make a uniform oil phase solution. Finally, add the water phase solution and the oil phase solution into the emulsification tank, and at the same time add 0.15-0.25 kg of emulsifier and mix evenly, and finally emulsify to form a viscous emulsion explosive matrix. Finally, add 0.4-0.7 kg to meet different engineering needs Additives to obtain high-density and high-energy emulsion explosives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com