LED light source, preparation method thereof and backlight module

A technology of LED light source and light source substrate, which is applied in the direction of light source, light source fixing, lighting and heating equipment, etc., can solve the problems of insufficient stability of green quantum film, high cost of the whole Mini LED display, serious light decay, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

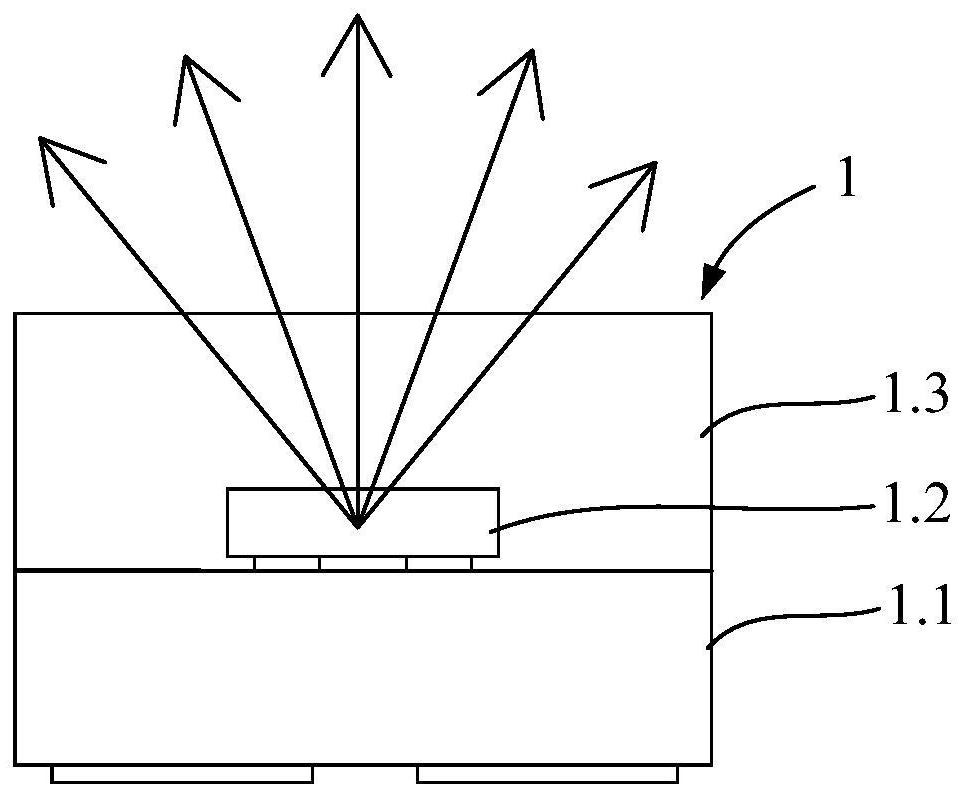

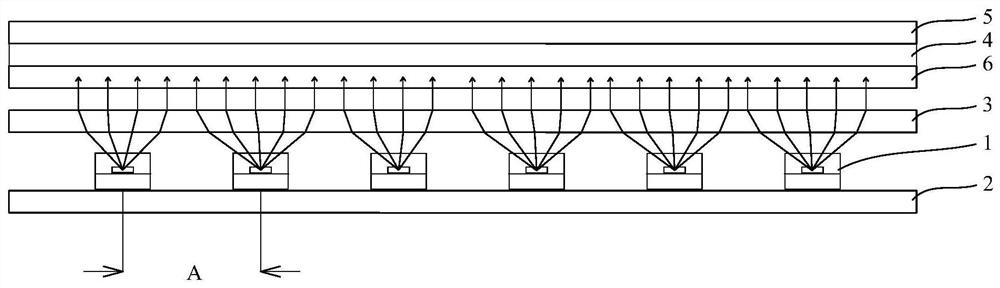

[0059] Such as Figure 4 to Figure 7 Shown is a schematic structural diagram of the first embodiment of the LED light source of the present invention. An LED light source in the present invention not only includes a light source substrate 1.1, a blue light chip 1.2, and a silica gel 1.3, but also includes a green light chip 1.4, and the green light chip 1.4 and the blue light chip 1.2 are fixed on the side of the light source substrate 1.1. The upper end, and the green chip 1.4 and the blue chip 1.2 are electrically connected to the light source substrate 1.1, the silica gel 1.3 is fixed on the upper end of the light source substrate 1.1 by molding, the green chip 1.4 and the blue chip 1.2 Packaged in the silica gel 1.3, the silica gel 1.3 protects the green chip 1.4 and the blue chip 1.2 and the parts where the green chip 1.4 and the blue chip 1.2 are electrically connected to the light source substrate 1.1. As mentioned above, the blue light chip 1.2 and the green light chi...

Embodiment 2

[0071] Such as Figure 9 Shown is a schematic structural diagram of the second embodiment of the LED light source of the present invention. An LED light source in the present invention, on the basis of Embodiment 1, a scattering layer 1.6 is fixedly provided on the upper end of the nano-filtering reflective coating 1.5. The scattering layer 1.6 is made of silica gel mixed with diffusion powder, wherein the diffusion powder and silica gel are physically mixed without chemical reaction.

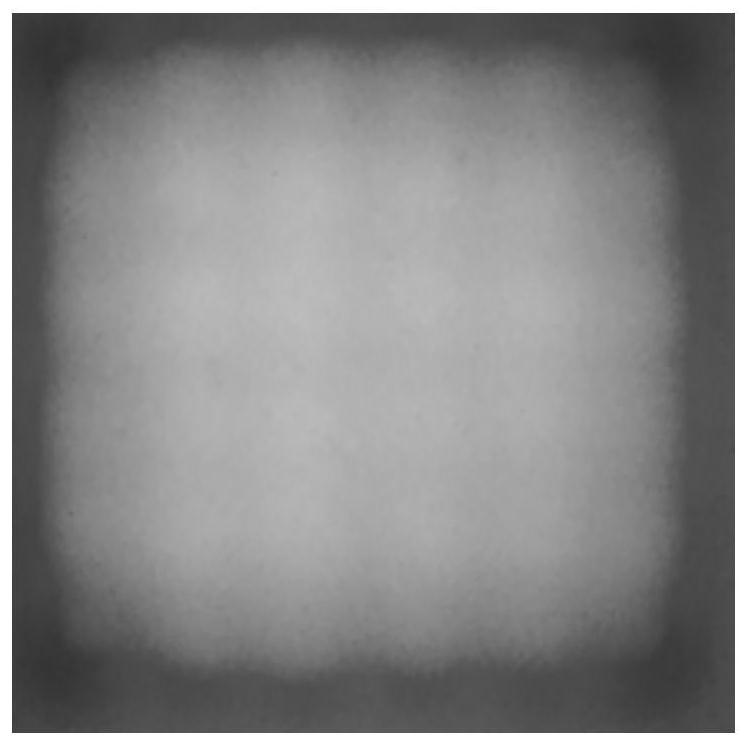

[0072] Most of the light scattered through the silica gel 1.3 for the first time will enter the scattering layer 1.6 through the nano-filter reflective coating 1.5, and undergo secondary scattering in the scattering layer 1.6, thus making the light emitted by the LED light source 1 more uniform; At the same time, the light reflected by the nano-filter reflective coating 1.5 and the module substrate 2 will fill the gap between adjacent LED light sources 1 . Thus, by using the silica gel 1.3 mi...

Embodiment 3

[0074] Such as Figure 12 As shown, the present invention also provides a method for preparing an LED light source, which specifically includes the following steps:

[0075] S1. Brushing solder paste: Print solder paste on the entire substrate, so that the solder paste adheres to the pad position to be solidified on the entire substrate. Wherein, the entire substrate can be cut into light source substrates 1.1 with a size of 1.0mm*1.0mm, and the light source substrates 1.1 are arranged in an array.

[0076] S2. Die-bonding: Flip multiple sets of blue light chips 1.2 and green light chips 1.4 respectively on the corresponding die-bonding positions on the entire substrate, and make the blue light chips 1.2 and green light chips 1.4 corresponding to the entire substrate after reflow soldering The welding pads of the blue light chip 1.2 and the green light chip 1.4 are welded together by solder paste, so as to realize the electrical connection between the blue light chip 1.2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| beam angle | aaaaa | aaaaa |

| beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com