Foaming cone for loudspeaker and preparation method and application thereof

A loudspeaker and paper cone technology, applied in the field of foam paper cones for loudspeakers and their preparation, can solve the problems of raw and auxiliary material ratio and preparation method of undisclosed foam paper cones.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

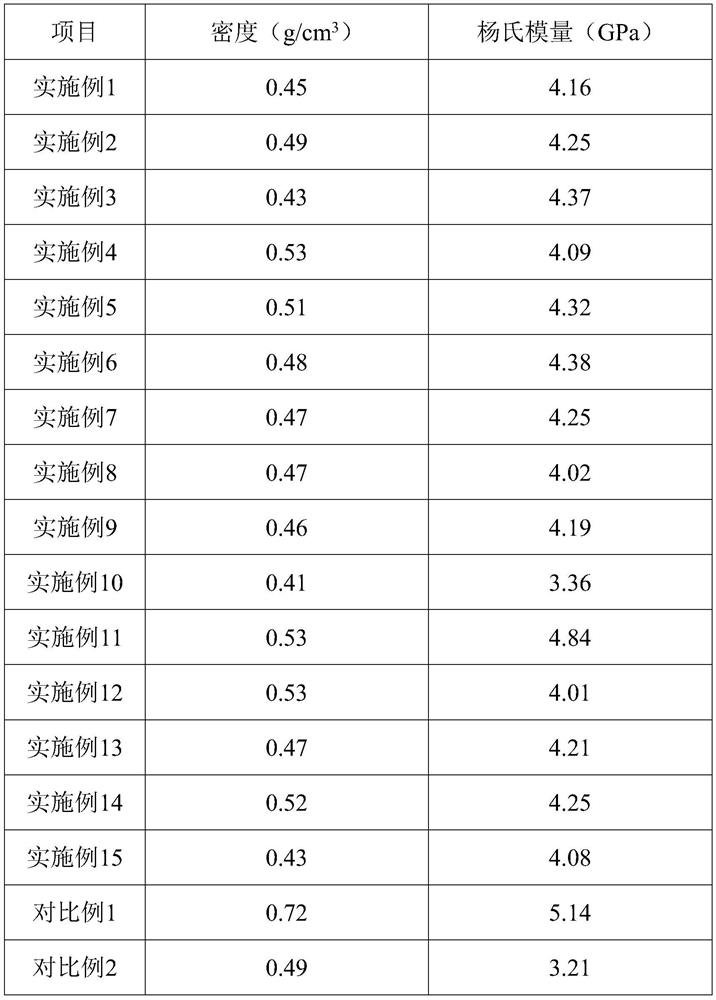

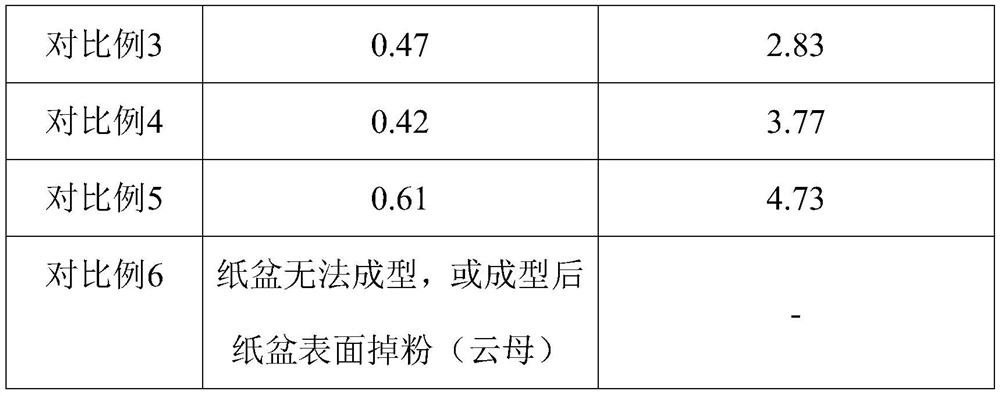

Examples

Embodiment 1

[0061] This embodiment provides a foamed paper cone for a speaker, and the foamed paper cone for a speaker is prepared by the following preparation method:

[0062] (1) Add 50 parts of bleached kraft wood pulp into the beater for beating. When the set beating degree of 30°SR is reached, add 8 parts of para-aramid fiber and continue beating for 30 minutes to make the pulp and para-aramid fiber Mix well, and get a 30°SR slurry after water filtration; mix 3 parts of quaternary ammonium cationic starch with 300 parts of water, heat and react at 90°C for 15 minutes, and obtain cured cationic starch;

[0063] (2) Dilute the slurry obtained in step (1) with water to obtain a fiber suspension, add 40 parts of mica and 16 parts of azodicarbonamide in turn while stirring, and after they are mixed evenly, add step (1) The cationic starch after the ripening that obtains is continued to stir 15min with the rotating speed of 120rpm, obtains the wet embryo of paper cone after filtering;

[...

Embodiment 2

[0067] This embodiment provides a foamed paper cone for a speaker, and the foamed paper cone for a speaker is prepared by the following preparation method:

[0068] (1) Add 60 parts of cotton pulp into the beater for beating. When the set beating degree of 40°SR is reached, add 10 parts of para-aramid fiber and continue beating for 30 minutes to fully mix the pulp and para-aramid fiber. Obtain the slurry of 41 ° SR after water filtration;

[0069] (2) Dilute the slurry obtained in step (1) with water to obtain a fiber suspension. While stirring, add 50 parts of mica and 14 parts of azodicarbonamide in turn. After mixing evenly, add 3 parts of cationic benzene Acrylic emulsion, continue to stir for 15min with the rotating speed of 100rpm, obtain paper cone wet embryo after filtering;

[0070] (3) Place the wet paper cone embryo obtained in step (2) in a high-temperature mold, press, and dry at 230° C. for 20 seconds to obtain a paper cone blank;

[0071] (4) Using a die-cutti...

Embodiment 3

[0073] This embodiment provides a foamed paper cone for a speaker, and the foamed paper cone for a speaker is prepared by the following preparation method:

[0074] (1) Add 50 parts of bamboo pulp into the beater for beating. When the set beating degree of 30°SR is reached, add 10 parts of para-aramid pulp and continue beating for 30 minutes to make the pulp and para-aramid pulp fully Mix and filter to obtain 32°SR slurry; mix 2 parts of quaternary ammonium cationic starch with 200 parts of water, heat and react at 90°C for 15 minutes, and obtain cured cationic starch;

[0075] (2) Dilute the slurry obtained in step (1) with water to obtain a fiber suspension, while stirring, add 50 parts of mica and 20 parts of azodicarbonamide in turn, and after they are mixed evenly, add step (1) The cationic starch after the ripening that obtains, continue to stir with the rotating speed of 80rpm 15min, after filtering, obtain paper pot wet embryo;

[0076] (3) Place the wet paper cone bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com