Single-layer MXene colloid as well as preparation method and application thereof

A colloidal, single-layer technology, applied in chemical instruments and methods, other chemical processes, nuclear engineering, etc., can solve problems that restrict MXene performance, reduce specific surface area utilization, limit applications, etc., achieve good selective adsorption performance and simple equipment , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

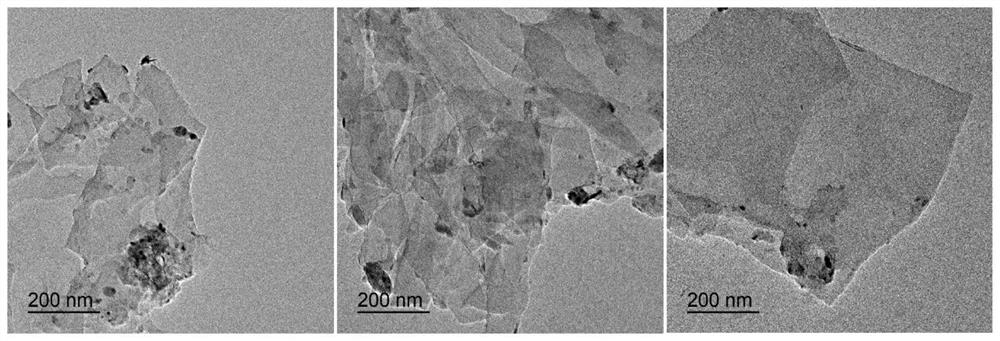

[0035] A monolayer Ti 3 C 2 T X The preparation method of colloid, comprises the following steps:

[0036] S1, respectively weigh Ti 3 AlC 2 2.000g (200mesh) of powder, 2.211g of anhydrous LiCl, 30mL of HF solution with a mass concentration of 40wt%;

[0037]First, add 30 mL of HF solution with a mass concentration of 40% into a polytetrafluoroethylene bottle, then add 2.211 g of anhydrous LiCl into the HF solution, and stir to dissolve to obtain solution A;

[0038] S2, slowly add Ti to solution A 3 AlC 2 Powder, the feeding time is 1min; after the feeding is completed, place the reaction mixture on a magnetic stirrer and stir for 30min, place the stirred mixed solution in an oven, set the oven temperature to 50-60°C and react for 24-48h;

[0039] S3. Take out the reacted mixed solution after cooling to room temperature in the oven, add 60 mL of HCl solution with a mass concentration of 18% into the plastic beaker, add the cooled mixed solution into the HCl solution, a...

Embodiment 2

[0061] A monolayer Ti 3 C 2 T X The preparation method of colloid is substantially the same as the method of embodiment 1, and its difference is,

[0062] In S1, weigh Ti respectively 3 AlC 2 Powder 2.000g (200mesh), anhydrous LiCl 2.000g, HF solution with a mass concentration of 40wt% 40mL;

[0063] In S7, add 60 mL of ethanol to the lower sediment of S6, and use a 750W ultrasonic machine to sonicate for 30 min in an ice bath;

[0064] In S9, collect the lower precipitate after centrifugation and add 40 mL of deionized water.

Embodiment 3

[0066] A monolayer Ti 3 C 2 T X The preparation method of colloid is substantially the same as the method of embodiment 1, and its difference is,

[0067] In S1, weigh Ti respectively 3 AlC 2 Powder 2.000g (200mesh), anhydrous LiCl 4.000g, HF solution with a mass concentration of 40wt% 40mL;

[0068] In S7, add 80 mL of ethanol to the lower precipitate of S6, and use a 750W ultrasonic machine to sonicate for 90 min in an ice bath;

[0069] In S9, collect the lower precipitate after centrifugation and add 60 mL of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com