Full-automatic intelligent vibration reduction control method and device for ball milling system of large smelting blast furnace coal mill

An intelligent vibration reduction and control method technology, applied in the direction of comprehensive factory control, grain processing, etc., can solve the problems of blocking the passage of finished coal powder to the screen, impaired production efficiency, large conveying volume and large tolerance of the feeder, etc. , to achieve the effect of eliminating short-term severe vibration, reducing the value of external noise and reducing the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

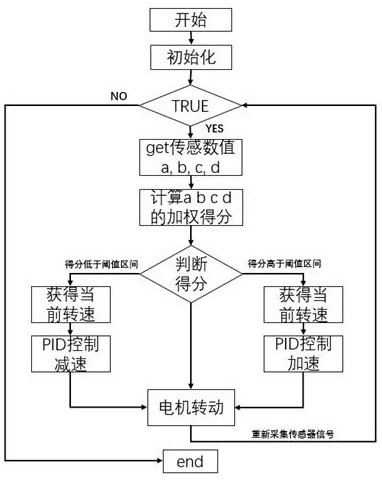

[0048] see Figure 1-4 , the embodiment of the present invention provides a large-scale smelting blast furnace coal mill ball mill system automatic intelligent vibration reduction control method, including the following steps:

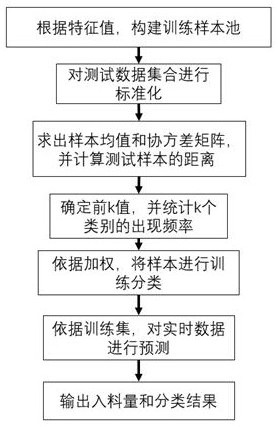

[0049] (1) Identify the types of raw coal entering the system, and the four types of raw coal are respectively configured with a base speed of v 1 , v 2 , v 3 , v 4 , respectively 15rad / min, 18rad / min, 21rad / min, 24rad / min. Set the optimal weight w for each raw coal maxi , i=1, 2, 3, 4, set the basic speed of the motor; refer to figure 2 , specifically, the identification method for the type of raw coal entering the system is:

[0050] Step 1. Establish a training set: Collect raw coal and coal gangue quality, pressure and other characteristic values through multi-dimensional sensors to generate a training sample set: a i (x i1 , x i2 ,...,x in ), where i is the number of samples, n is the number of features, and the labels "1", "2", "3", ...

Embodiment 2

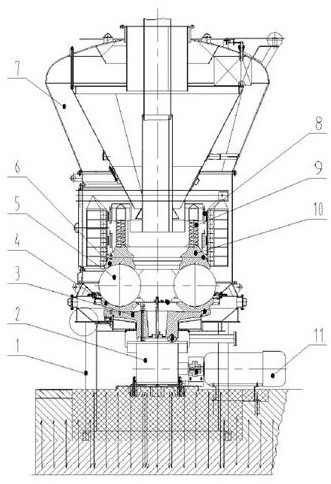

[0070] refer to figure 1 , the embodiment of the present invention provides a large-scale smelting blast furnace coal mill ball mill system automatic intelligent vibration reduction control device, including a main motor 11, a reduction box 2, a tray 3, a lower grinding ring 4, a grinding ball 5, an upper grinding ring 6, A parameter acquisition system, a PID controller and an execution module; the main motor 11 and the reduction box 2 are arranged on the base 1, the main motor 11 is sequentially driven and connected with the reduction box 2, the tray 3 and the lower grinding ring 4, and the upper grinding ring 6 and The grinding ball 5 is arranged above the lower grinding ring 4; the parameter acquisition system includes displacement sensors, pressure sensors, acceleration sensors and noise sensors; the displacement sensors, pressure sensors, and acceleration sensors are all arranged below the lower grinding ring 4, and the PID controller The signal is connected to respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com