Ostomy chassis cutting die capable of grinding edge

A stoma and chassis technology, applied in the direction of manufacturing tools, machine tools suitable for grinding the edge of workpieces, and parts of grinding machine tools, etc., can solve problems such as infection, different sizes of enterostomy, cumbersome operation, etc., and reduce damage , Ingenious structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific drawings and embodiments.

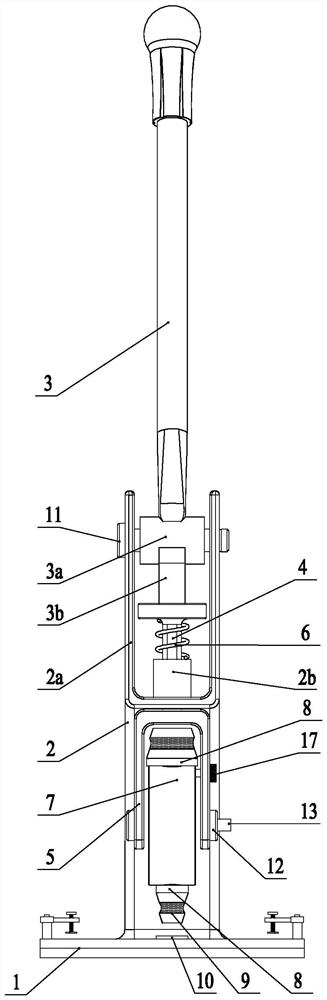

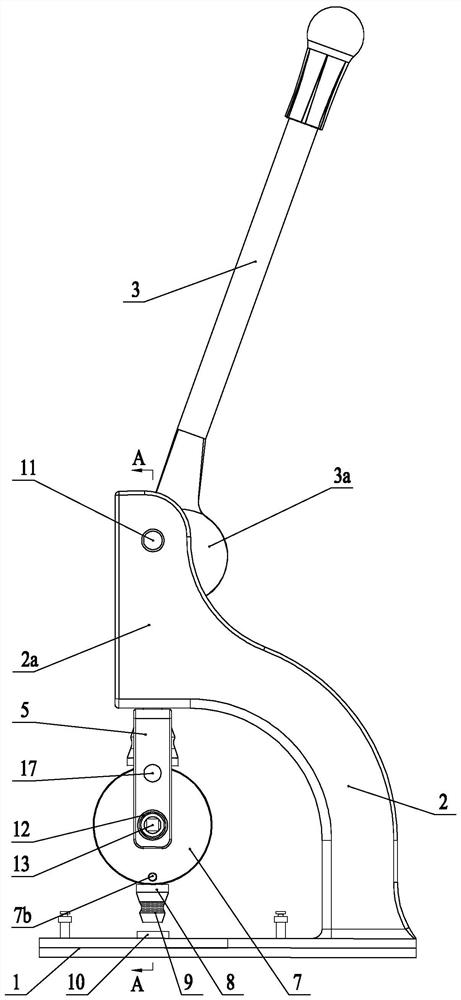

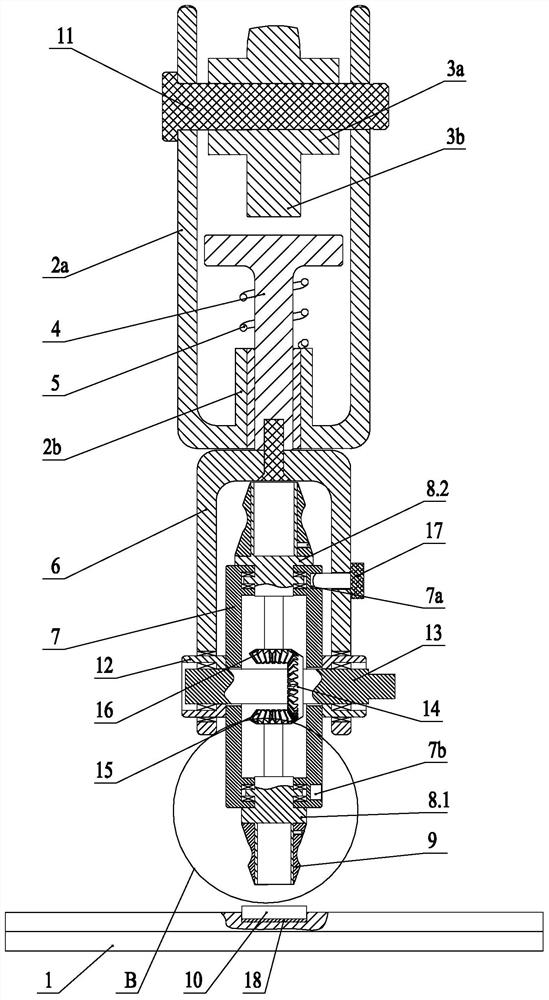

[0021] Such as Figure 1 to Figure 4 As shown, the embodiment discloses a cutting mold for stoma chassis that can be edged, including a base 1, a cantilevered support column 2, a handle 3, a lower pressure rod 4, a fork frame 5, a spring 6, and a disc seat 7 , mold head 8, grinding wheel 9 and mold seat 10, a pressing mechanism is installed on the base 1, the lower end of the cantilevered support column 2 is fixed on the rear part of the upper surface of the base 1, and the cantilevered support column 2 The front end cantilever protrudes forward; the front end of the cantilever support column 2 is provided with a mounting platform 2a, and the front end of the handle 3 is integrally provided with a cylinder 3a, and the cylinder 3a is hinged on the installation surface through the first pin shaft 11. The upper part of the platform 2a, the lower part of the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com