Preparation method of epoxy silane coupling agent oligomer

An epoxy silane coupling agent and oligomer technology, applied in the polymer field, can solve the problems of lower-than-expected modification effect, large equivalent amount of small-molecule coupling agent, and coupling agent that cannot meet low surface energy materials. , to achieve the effect of increasing water and oil repellency, toughening, and promoting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

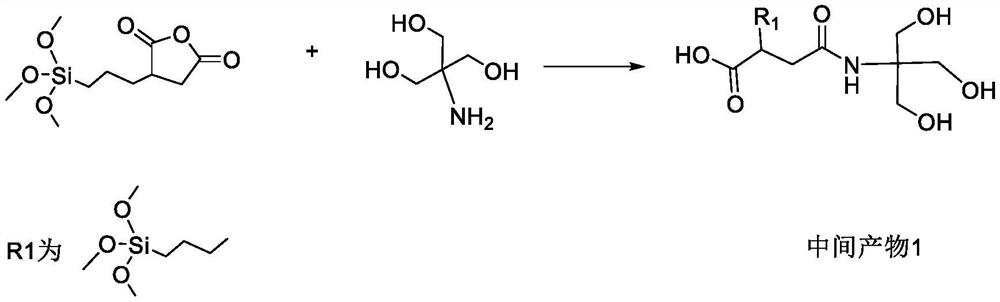

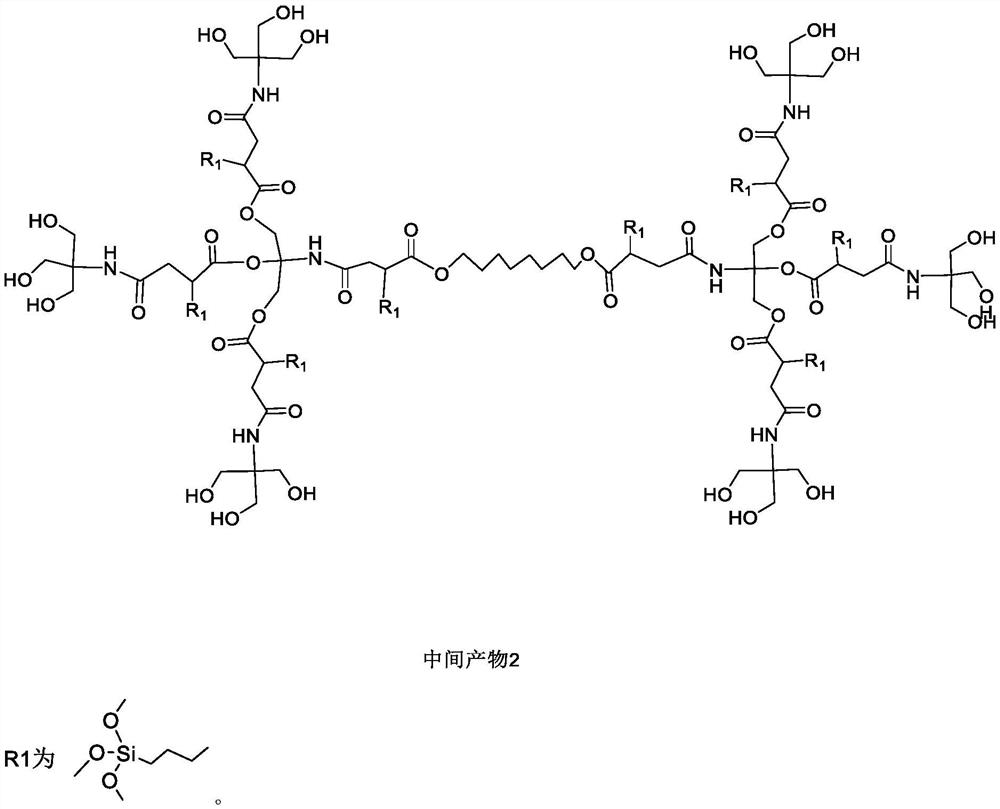

[0032] Described dendritic silicone is made through the following steps:

[0033] Step A: [3-(trimethoxysilyl) propyl] succinic anhydride and trihydroxymethylaminomethane are added to a four-necked flask, then ethanol is added to dissolve it completely, and then the four-necked flask is placed in an oil bath Heated to 70°C in a medium temperature, and refluxed for 10h, then lowered to room temperature, transferred the solution to a container, placed in an oven and dried under vacuum at 35°C to obtain intermediate product 1, in which [3-(trimethoxysilyl) The consumption of propyl] succinic anhydride, tris, ethanol is 0.1mol:0.1mol:150mL;

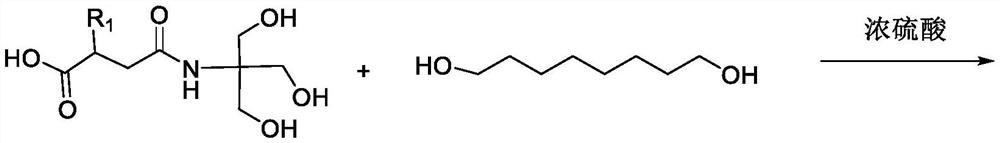

[0034] Step B: Add the intermediate product 1 and 1,2-octanediol obtained in step A into a four-necked flask, mix well, slowly add concentrated sulfuric acid, and heat the temperature of the reaction system to 80 ° C, under nitrogen protection After stirring and reacting for 3 hours, intermediate product 2 was finally obtained, wherein the m...

Embodiment 2

[0037] Dendritic silicones are made through the following steps:

[0038] Step A: [3-(trimethoxysilyl) propyl] succinic anhydride and trihydroxymethylaminomethane are added to a four-necked flask, then ethanol is added to dissolve it completely, and then the four-necked flask is placed in an oil bath Heated to 70°C in a medium temperature, and refluxed for 10h, then lowered to room temperature, transferred the solution to a container, placed in an oven and dried under vacuum at 35°C to obtain intermediate product 1, in which [3-(trimethoxysilyl) The consumption of propyl] succinic anhydride, tris, ethanol is 0.12mol:0.1mol:200mL;

[0039]Step B: Add the intermediate product 1 and 1,2-octanediol obtained in step A into a four-necked flask, mix well, slowly add concentrated sulfuric acid, and heat the temperature of the reaction system to 80 ° C, under nitrogen protection After reacting under stirring for 3 hours, the intermediate product 2 was finally obtained, wherein the mas...

Embodiment 3

[0042] Dendritic silicones are made through the following steps:

[0043] Step A: [3-(trimethoxysilyl) propyl] succinic anhydride and trihydroxymethylaminomethane are added to a four-necked flask, then ethanol is added to dissolve it completely, and then the four-necked flask is placed in an oil bath Heated to 70°C in a medium temperature, and refluxed for 10h, then lowered to room temperature, transferred the solution to a container, placed in an oven and dried under vacuum at 35°C to obtain intermediate product 1, in which [3-(trimethoxysilyl) The consumption of propyl] succinic anhydride, tris, ethanol is 0.14mol:0.1mol:250mL;

[0044] Step B: Add the intermediate product 1 and 1,2-octanediol obtained in step A into a four-necked flask, mix well, slowly add concentrated sulfuric acid, and heat the temperature of the reaction system to 80 ° C, under nitrogen protection After reacting under stirring for 3 hours, the intermediate product 2 was finally obtained, wherein the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com