Method for preparing natural polymer water-absorbing material by taking starch cellulose factory slag as raw material

A starch cellulose and natural polymer technology, applied in the field of preparing natural polymer water-absorbing materials, can solve the problems of complex production process, high production cost, poor use effect, etc., achieve low production cost, reduce sewage treatment, and simplify production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

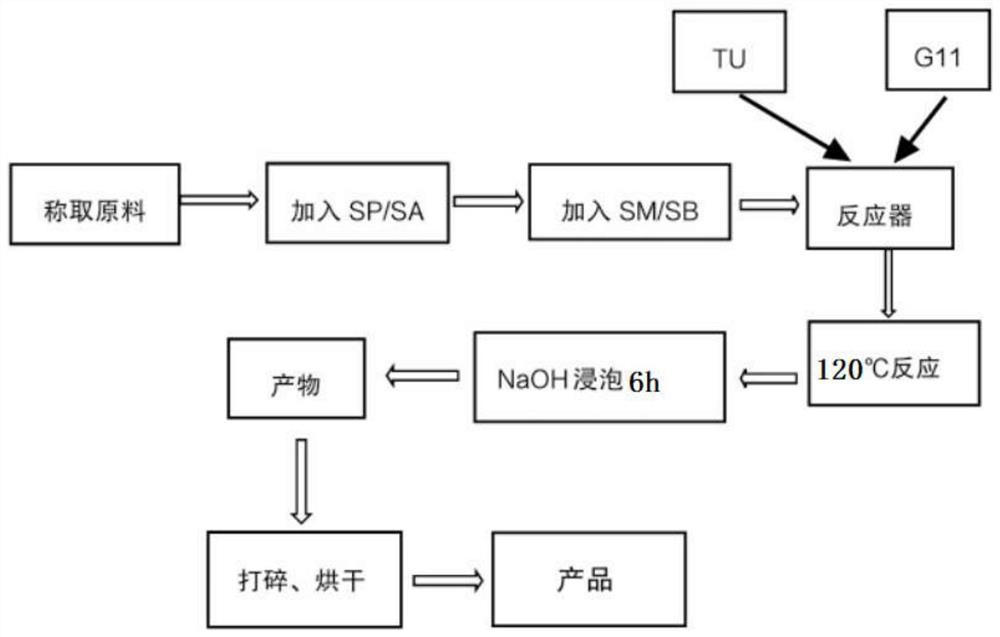

Image

Examples

preparation example Construction

[0036] A preparation method of a natural polymer water-absorbing material using starch cellulose residue as a raw material, comprising the following steps:

[0037] Step (1), according to the mass ratio of starch cellulose slag: SP: SA: SB: SM: bentonite: G11: sodium hydroxide = 200: 10: 300: 200: 2: 3: 20: 100, accurately weigh the ratio The amount of each component is ready for use;

[0038] Step (2), adding accurately weighed starch cellulose slag into distilled water of 5 times the mass and mixing, stirring evenly, and leaving it to stand for use;

[0039] Step (3), adding accurately weighed SP into 50 times the mass of distilled water for mixing, fully stirring and dissolving under water bath conditions, until no new precipitation is produced, and then adding it to the raw material mixture in step (2), Stir again evenly;

[0040] Step (4), adding accurately weighed SA to the mixed solution in step (3), fully stirring;

[0041]In step (5), the accurately weighed SB and ...

Embodiment

[0055] 1. Use an electronic balance to weigh 2.0g of starch cellulose slag, pour all of it into a 100ml glass beaker, use a 30ml graduated cylinder to measure 10ml of distilled water, add it to the beaker, stir evenly with a glass rod, and let it stand;

[0056] 2. Weigh 0.1g SP into another beaker, add 5ml of distilled water, place the bottom of the beaker in a water bath, stir with a glass rod until the drug dissolves and no new precipitates are formed, add the raw materials to the beaker with uniform stirring, and use it again Stir the glass rod evenly;

[0057] 3. Measure 3ml SA, add it to the raw material beaker, stir well;

[0058] 4. Weigh 2g of SB and 0.02g of SM into a beaker, add 10ml of distilled water, place the bottom of the beaker in a water bath, stir with a glass rod until the drug dissolves and no new precipitation occurs, add it to the raw material beaker, and use glass again Stir the stick evenly;

[0059] 5. Weigh 0.03g of bentonite and 0.2g of G11 into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap