MXene/polyimide nanofiber aerogel and preparation method and application thereof

A technology of polyimide fibers and nanofibers, applied in fiber processing, fiber chemical characteristics, electrical components, etc., can solve problems such as high process difficulty, poor shielding performance, unsatisfactory shape or mechanical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

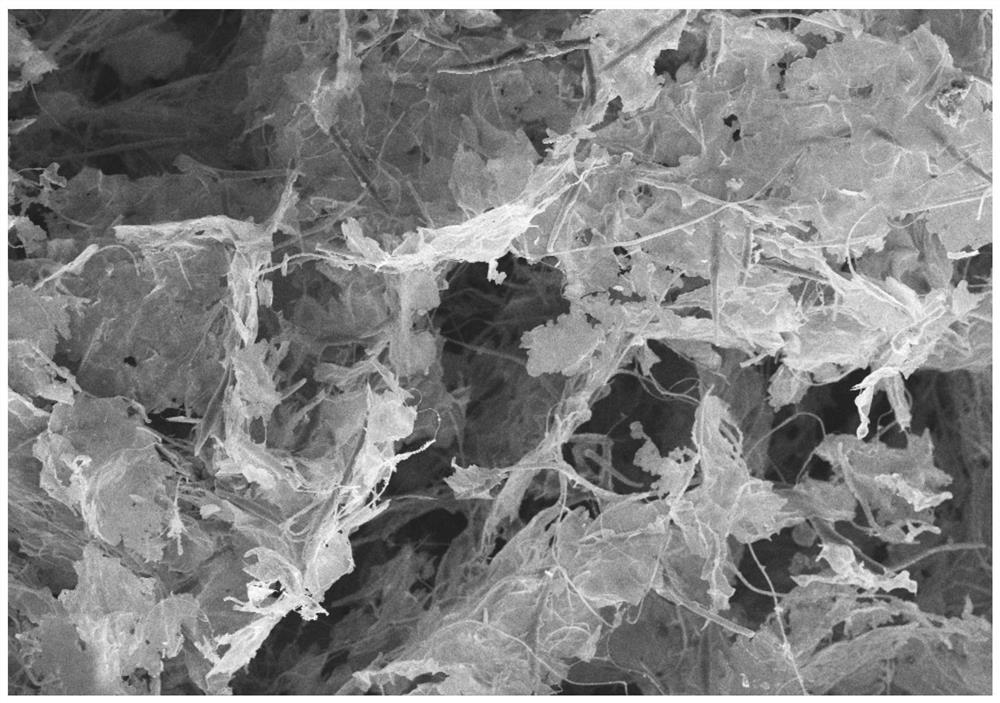

[0029] Such as figure 2 Shown, the present invention provides a kind of MXene / polyimide fiber airgel, and it contains MXene and polyimide fiber, and polyimide fiber is polyimide nanofiber, and described polyimide nanofiber The MXene is distributed in the polyimide nanofiber in the form of a sheet, and the airgel has a thickness of 2 mm to 8 mm.

Embodiment 2

[0031] The preparation method of the MXene / polyimide fiber airgel applied to the field of electromagnetic shielding provided by embodiment 2 comprises the following steps:

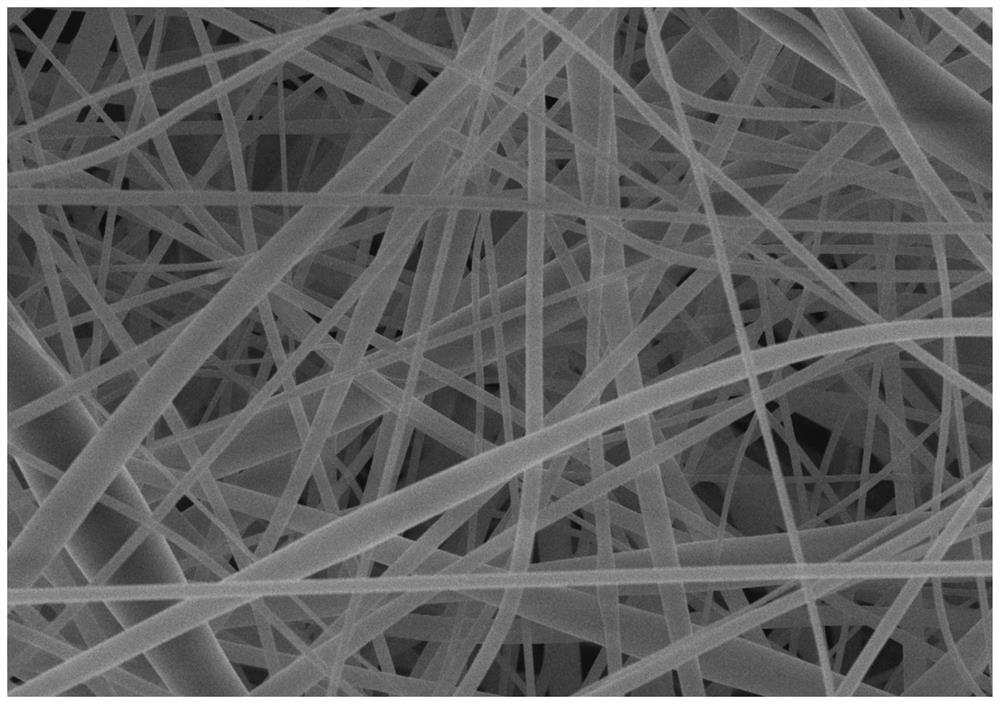

[0032] (1) The polyamic acid solution was diluted to 12wt% with DMF, and magnetically stirred for 12h. The polyamic acid nanofibers were prepared by electrospinning; the advancing speed was 1ml / h, the voltage was 15kV; the fibers were received by aluminum foil, and the receiving distance was 20cm. Put the fiber membrane in a ventilated place to evaporate the solvent.

[0033] (2) Cut the fibrous membrane prepared in step (1) into square pieces of 1 cm×1 cm, mix with water, and add 10 mg / ml of the fibrous membrane. Break the fiber film with a high-speed mixer to obtain a polyamic acid nanofiber / water mixture; the speed of the high-speed mixer is 6000r / min;

[0034] (3) Add polyethylene glycol to the polyamic acid nanofiber / water mixture prepared in step (2), and the amount of polyethylene glycol added is ...

Embodiment 3

[0040] The preparation method of the MXene / polyimide fiber airgel applied to the field of electromagnetic shielding provided by embodiment 3 comprises the following steps:

[0041] (1) Dilute the polyamic acid solution to 12 wt% with DMF, and stir it magnetically for 12 hours. The polyamic acid nanofibers were prepared by electrospinning; the advancing speed was 1ml / h, the voltage was 15kV; the fibers were received by aluminum foil, and the receiving distance was 20cm. Put the fiber membrane in a ventilated place to evaporate the solvent.

[0042](2) Cut the fibrous membrane prepared in step (1) into square pieces of 1 cm×1 cm, mix with water, and add 10 mg / ml of the fibrous membrane. Break the fiber film with a high-speed mixer to obtain a polyamic acid nanofiber / water mixture; the speed of the high-speed mixer is 6000r / min;

[0043] (3) Add polyethylene glycol to the polyamic acid nanofiber / water mixture prepared in step (2), and the amount of polyethylene glycol added is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com