Sealant with high hardness and ceramic-like texture and preparation method thereof

A kind of beautifying agent and high hardness technology, applied in the field of caulking agent, it can solve the problems of poor resistance to dirt, low hardness of cured product, mildew, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

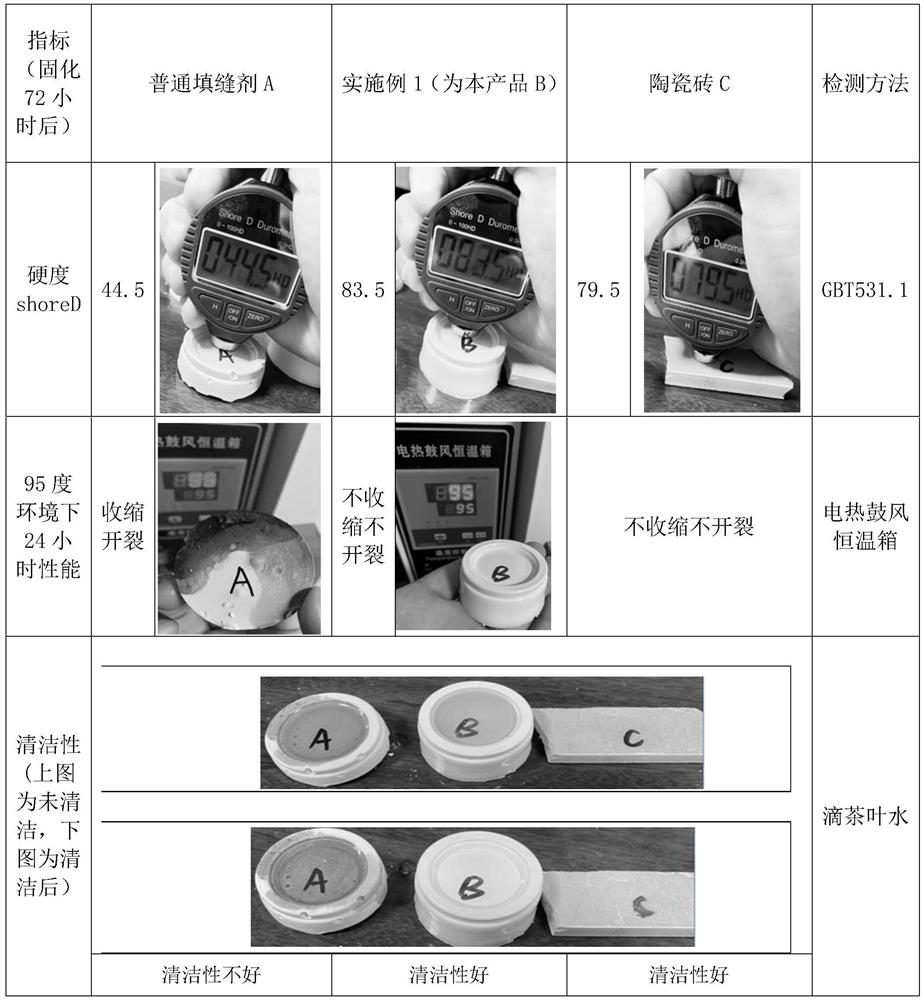

Examples

Embodiment 1

[0048] In order to solve the problems of the technologies described above, the present invention is realized in the following manner:

[0049] This embodiment relates to a high-polymerization, high-strength and high-hardness beauty joint agent, including A component and B component, wherein A component includes the following raw materials in parts by weight:

[0050] 75 parts by weight of E-51 epoxy resin, 5 parts by weight of propylene glycol methyl ether acetate, 1 part by weight of fumed silica;

[0051] Wherein component B comprises the raw material of following weight portion:

[0052] 20 parts by weight of 1.3BAC (1,3-cyclohexanedimethylamine), 20 parts by weight of propylene glycol methyl ether acetate, 10 parts by weight of E-51 epoxy resin, 1 part by weight of fumed silica, and 1 part by weight of pearl powder;

[0053] 1) Preparation of component A

[0054] Put E-51 epoxy resin, propylene glycol methyl ether acetate and fumed silica into the disperser in no particu...

Embodiment 2

[0064] In order to solve the problems of the technologies described above, the present invention is realized in the following manner,

[0065] This embodiment relates to a high-polymerization, high-strength and high-hardness beauty joint agent, including A component and B component, wherein A component includes the following raw materials in parts by weight:

[0066] 78 parts by weight of E-51 epoxy resin, 6 parts by weight of propylene glycol methyl ether acetate, 2 parts by weight of fumed silica;

[0067] Wherein component B comprises the raw material of following weight portion:

[0068] 23 parts by weight of 1.3BAC (1,3-cyclohexanedimethylamine), 22 parts by weight of propylene glycol methyl ether acetate, 12 parts by weight of E-51 epoxy resin, 5 parts by weight of fumed silica, 4 parts by weight of pearl powder;

[0069] 1) Preparation of component A

[0070] Put E-51 epoxy resin, propylene glycol methyl ether acetate and fumed silica into the disperser in no particul...

Embodiment 3

[0080] In order to solve the problems of the technologies described above, the present invention is realized in the following manner,

[0081] This embodiment relates to a high-polymerization, high-strength and high-hardness beauty joint agent, including A component and B component, wherein A component includes the following raw materials in parts by weight:

[0082] 81 parts by weight of E-51 epoxy resin, 8 parts by weight of propylene glycol methyl ether acetate, 4 parts by weight of fumed silica;

[0083] Wherein component B comprises the raw material of following weight portion:

[0084] 1.3BAC (1,3-cyclohexanedimethylamine) 25 parts by weight, 25 parts by weight of propylene glycol methyl ether acetate, 15 parts by weight of E-51 epoxy resin, 7 parts by weight of fumed silica, 6 parts by weight of pearl powder;

[0085] 1) Preparation of component A

[0086] Put E-51 epoxy resin, propylene glycol methyl ether acetate and fumed silica into the disperser in no particular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com