Heat carrier direct heat supply type multi-stage series turbulent bed pyrolysis stripping reactor

A technology of turbulent bed and reactor, which is applied in the field of heat carrier direct heating type multi-stage series turbulent bed pyrolysis and stripping reactor, which can solve the problem of low heat transfer efficiency, shorten the reaction time and reduce energy consumption , Improve the effect of heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

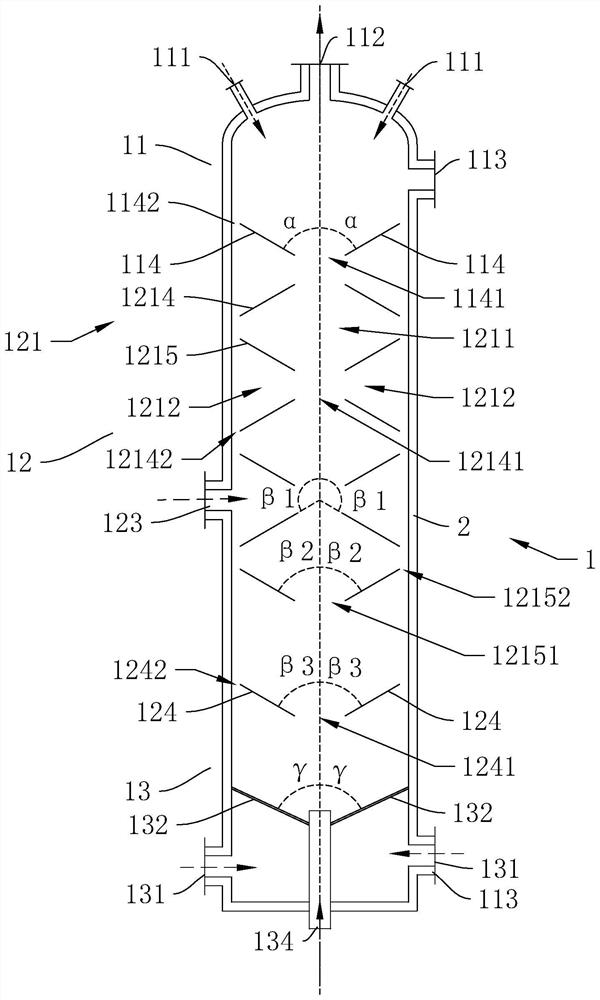

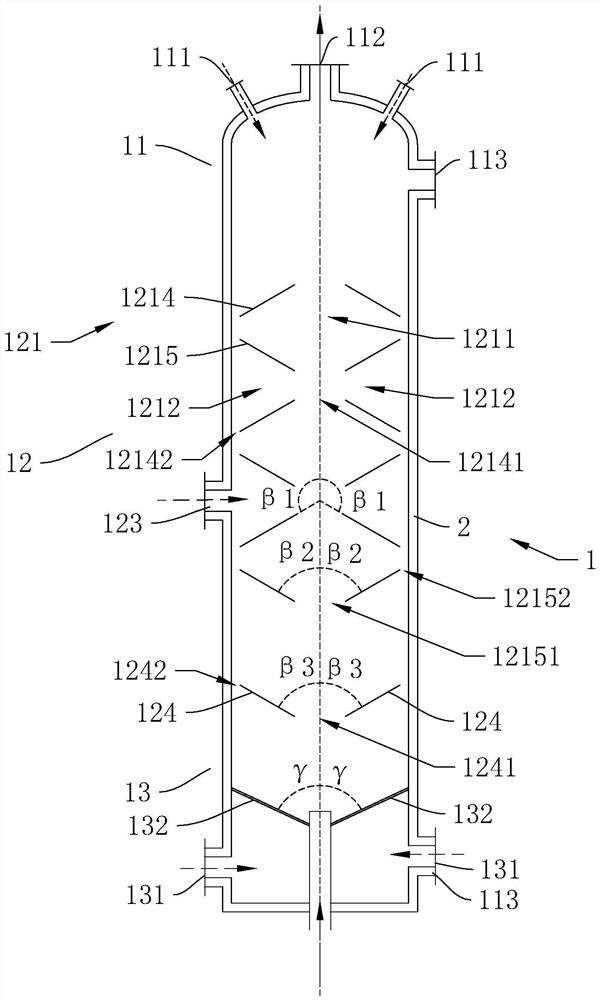

[0042] The embodiment of the present application discloses a multi-stage serial turbulent bed pyrolysis stripping reactor directly fed by a heat carrier. refer to figure 1 , the heat carrier directly feeds the heat type multi-stage series turbulent bed pyrolysis stripping reactor, including a shell 1, a refractory and heat-insulating lining 2 between the inner wall and the outer wall of the shell 1, and the shell 1 is distributed from top to bottom There are three areas, the upper reaction section 11, the middle reaction section 12 and the lower reaction section 13, which communicate with each other.

[0043] The high-temperature heat carrier rises from the lower reaction stage 13 to the upper reaction stage 11; the organic solid waste descends from the upper reaction stage 11 to the lower reaction stage 13; in the middle reaction stage 12, the descending organic solid waste directly contacts with the ascending high-temperature heat carrier to exchange heat, and the organic so...

Embodiment 2

[0069] The difference between this embodiment and Embodiment 1 is that there is no material distribution plate 114 in the upper reaction section 11 , and the organic solid waste directly falls into the uppermost upper deflector 1214 in the reaction middle section 12 .

Embodiment 3

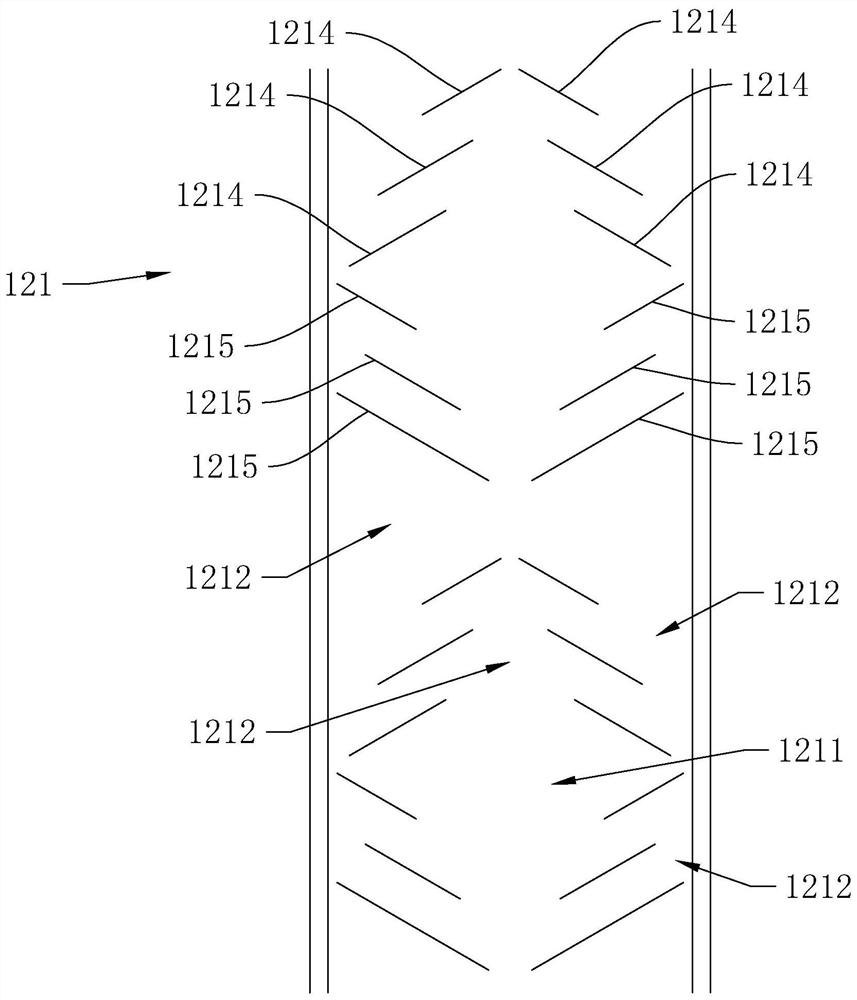

[0071] refer to image 3 , The difference between this embodiment and Embodiment 1 is that the structure of the turbulent micro-reaction bed 121 is different. Each group of turbulent micro-reaction beds 121 is composed of 3 upper deflectors 1214 and 3 lower deflectors 1215, and are bidirectionally symmetrical with the central axis of the shell 1 as the central axis and arranged in a ladder shape; the 3 upper deflectors The flow plates 1214 may be arranged at unequal intervals or at equal intervals.

[0072] The central area between the first upper deflector 1214 and the first lower deflector 1215 of each group constitutes the main reaction zone 1211 of this group of turbulent micro-reaction beds 121; 3 upper deflectors 1214 and shell Three secondary reaction zones 1212 are formed in the annular gap area between the inner walls of the body 1; three secondary reaction zones 1212 are formed in the central areas of the three upper deflectors 1214; the second and third lower defle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com