A method for preparing beryllium-copper master alloy by vacuum consumable arc melting

A vacuum consumable arc and master alloy technology, applied in the field of metal material manufacturing, can solve problems such as high cost, high energy consumption, pollution, etc., and achieve the effect of good product purity and quality, and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

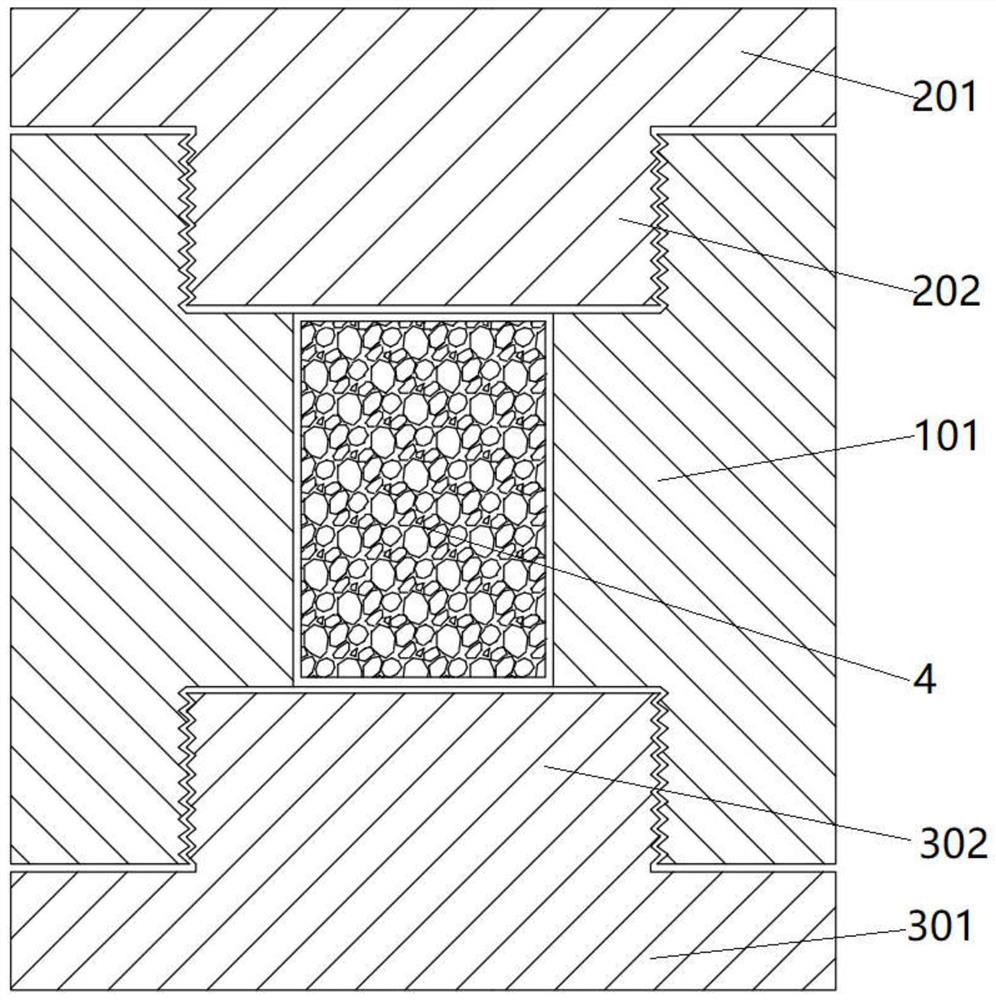

Embodiment 1

[0075] A beryllium-copper master alloy with a nominal beryllium content of 8 wt% and a nominal copper content of 92 wt% was prepared. The amount of carbon equivalent and beryllium oxide conforms to stoichiometry (according to 2BeO+C=2Be+CO 2 Calculate, the same below), and add 0.5% in excess (that is, add graphite powder at 1.005 times the carbon equivalent, the same below). The amount of copper powder is calculated according to the beryllium content in the target beryllium-copper master alloy based on the beryllium generated by the above-mentioned carbothermal reduction reaction. According to the calculated raw materials, copper powder, beryllium oxide powder and graphite powder are mixed evenly to obtain a mixed powder. Before the beryllium oxide is mixed, it is coated with PVA (by spraying method, the same below). The amount of PVA is beryllium oxide powder of 1wt%. Use 1.5t / cm of mixed powder 2 The pressure is pressed into a slab of 2mm*100mm*400mm, and then rolled with...

Embodiment 2

[0101] Prepare a beryllium-copper master alloy with a nominal beryllium content of 10% mass fraction and a nominal copper content of 90%. The amount of carbon equivalent and beryllium oxide is stoichiometric, and an excess of 1.0% is added. The amount of copper powder is calculated according to the beryllium content in the target beryllium-copper master alloy based on the beryllium generated by the above-mentioned carbothermal reduction reaction. The calculated raw material copper powder, beryllium oxide powder and graphite powder are mixed evenly to obtain mixed powder. Before the beryllium oxide is mixed, it is coated with PVA, and the amount of PVA is 1% of the mass fraction of beryllium oxide. Using 1.5t / cm 2 Press the mixed powder into a plate of 2mm*100mm*400mm, and then roll it with a rolling mill with a roll gap of 1mm. The pieces obtained by rolling are further broken into billet powder with a particle size of no more than 1mm, and then annealed at 280°C for 1 hour,...

Embodiment 3

[0110] Repeat Comparative Example 10, the only difference is that the green body is not sintered in a hot isostatic pressing furnace, specifically, the green body is sintered in an ordinary sintering furnace and the graphite mold described in Example 1, and the green body is loaded in In the graphite mold, the graphite mold is then placed in a common sintering furnace for sintering.

[0111] The working electrode performed well in the process of vacuum consumable electrode arc melting furnace, no fracture occurred, and the melting process was successfully completed. The beryllium content of beryllium copper is 12.10% and the copper content is 87.90% by sampling from the beryllium copper master alloy rod obtained in the crystallizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com