Microwave plasma CVD (chemical vapor deposition) monocrystal diamond preparation device capable of improving stability and monocrystal diamond preparation method

A microwave plasma, single crystal diamond technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the cost of power microwave power supply, the high maintenance cost of microwave generators, the rupture of diamond crystal lattice, the production of High cost and energy consumption, to achieve the effect of low maintenance cost, improved yield and reduced equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

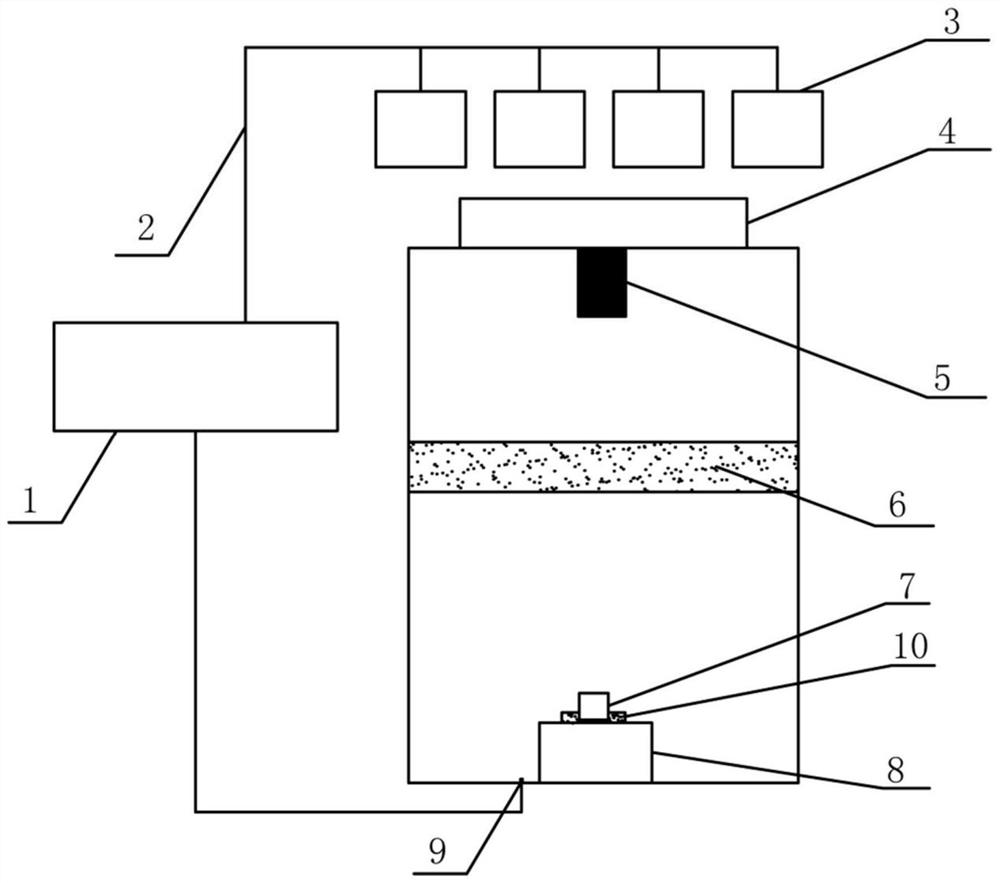

[0035] A device for preparing single crystal diamond by microwave plasma CVD with improved stability, the device includes a microwave generator 3, a waveguide 4 is arranged under the microwave generator 3, the waveguide 4 is connected to an antenna 5, and a microwave medium is arranged under the antenna 5 Window 6, a molybdenum holder 8 is provided below the microwave dielectric window 6, a single crystal diamond seed crystal 7 is arranged above the molybdenum holder 8, and the antenna 5, the microwave dielectric window 6, the molybdenum holder 8 and the single crystal diamond seed crystal 7 are placed inside the cavity .

[0036] Preferably, the microwave generator 3 includes a main microwave generator and several spare microwave generators, and the power supply 1 is electrically connected to a main microwave generator and several spare microwave generators. It is used to control the number of microwave generators 3 put into operation or to control the output power of the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com