Titanium alloy flexible package wear-resistant coating and preparation method thereof

A technology of wear-resistant coating and titanium alloy, which is applied in the direction of metal material coating process and coating, can solve the problems of poor wear resistance of titanium alloy, and achieve the effects of low cost, improved wear resistance and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

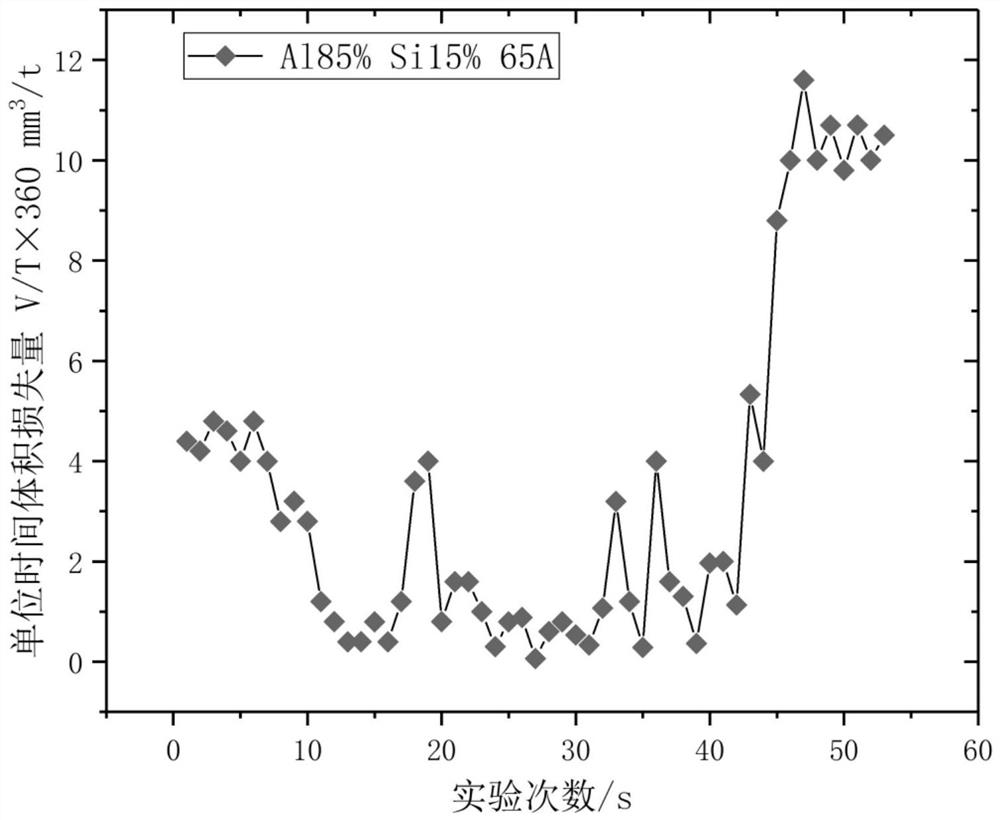

[0032] Put the Al-15Si alloy powder with a particle size of 100 mesh into the synchronous powder feeder of the plasma welder, and use the plasma welder to weld the cladding coating on the surface of the TC4 titanium alloy in the form of continuous plasma welding. The welding current is 65A, and send The powder gas flow rate is 3.5 1atm Nl / min. If the multi-pass welding process is performed, the completed cladding layer should be cleaned of slag before the next cladding layer is welded to ensure that the coating surface is smooth. When performing welding cladding, the overlapping of the next cladding layer and the previous cladding layer should not be less than 1 / 2. The target Al-Si soft packaging wear-resistant coating can be prepared.

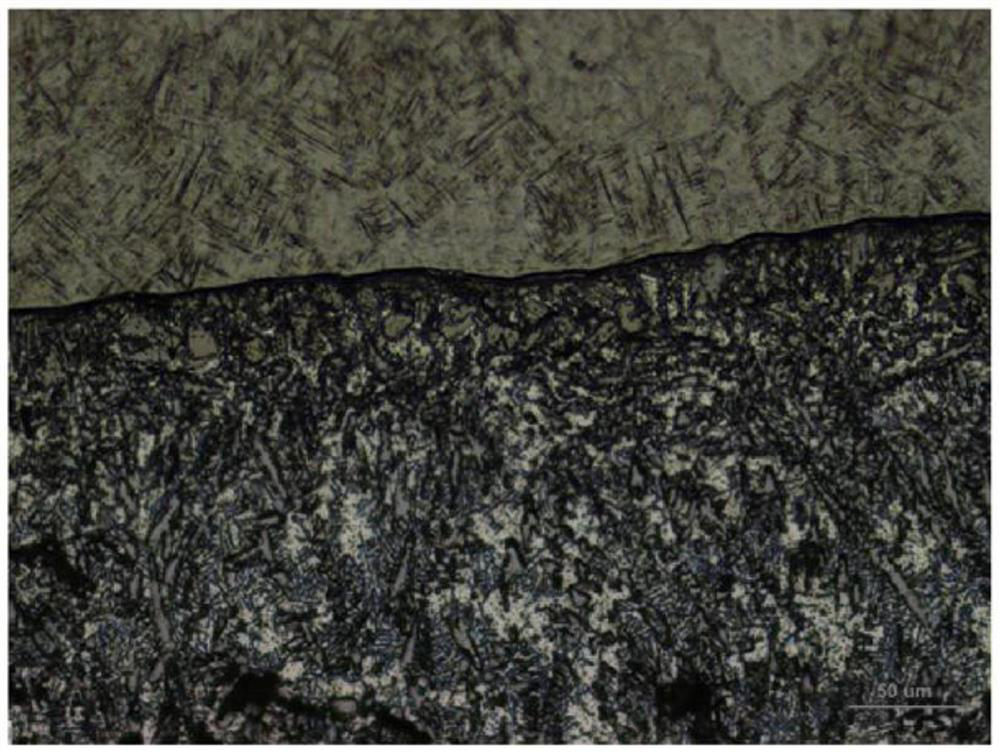

[0033] Such as figure 1 As shown, the composition of the coating is primary Si and (α+Si) eutectic structure, and there is a metallurgical bond between the coating and the substrate. The primary silicon is evenly distributed in the coating,...

Embodiment 2

[0035] Put the Al-25Si alloy powder with a particle size of 100 mesh into the synchronous powder feeder of the plasma welder, and use the plasma welder to weld the cladding coating on the surface of the TC4 titanium alloy in the form of continuous plasma welding, with a welding current of 60A. The powder gas flow rate is 3.5 1atm Nl / min, and the target Al-Si flexible packaging wear-resistant coating is prepared, and the silicon is evenly distributed in the coating.

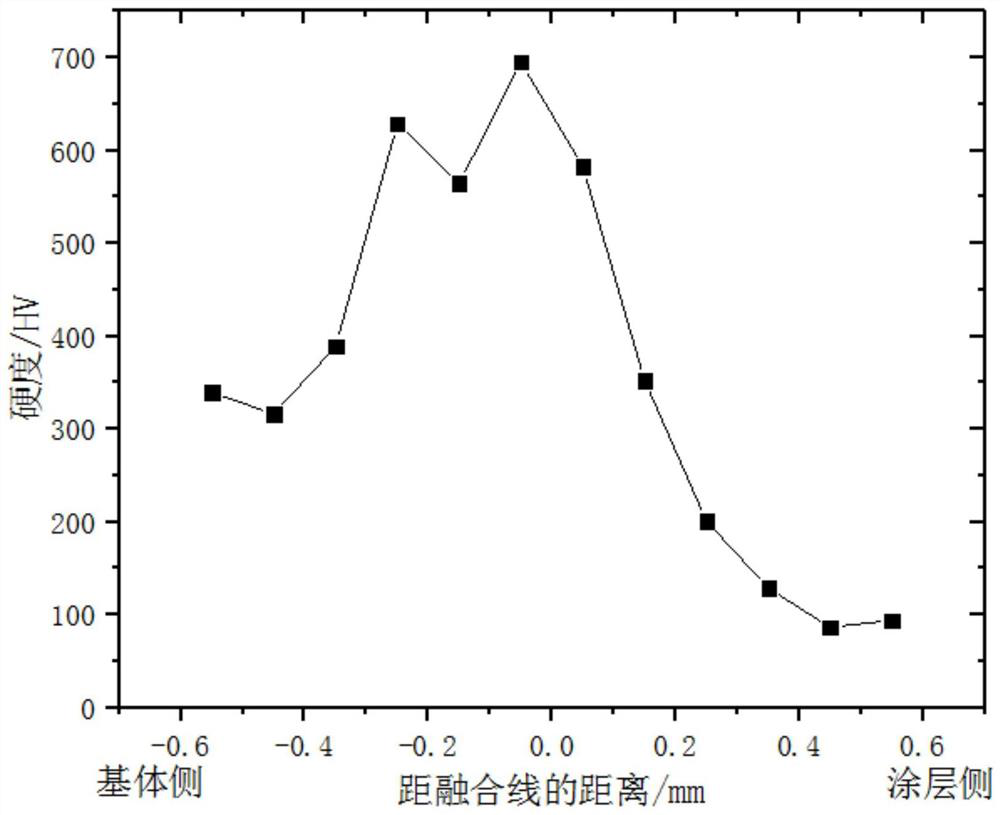

[0036] A kind of TC4 titanium alloy Al-Si soft packaging wear-resistant coating of the present invention, as image 3 As shown, on the cross-section of this coating, the microhardness analysis was carried out. In the coating, α-Al is the main component of the coating, with a hardness of 60-100HV, and the reason for the high hardness of the structure in the transition zone is the Ti-Al-based metal formed in the interface bonding zone between the coating and the substrate. inter-compound, which has the characterist...

Embodiment 3

[0038] Put the Al-15Si alloy powder with a particle size of 100 mesh into the synchronous powder feeder of the plasma welder, and use the plasma welder to weld the cladding coating on the surface of the TC4 titanium alloy in the form of continuous plasma welding, with a welding current of 60A. The powder gas flow rate is 3.5 1atm Nl / min, and the target Al-Si flexible packaging wear-resistant coating is prepared, and the silicon is evenly distributed in the coating. It was found that the wear resistance of the coating was three times that of the base TC4 titanium alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com