Intermediate support bearing assembly and polyurethane composite material for the assembly

An intermediate support and polyurethane technology, applied in the field of auto parts, can solve the problem that the intermediate support bearing assembly cannot be adjusted and compensated for the transmission shaft of the automobile, and achieve the effect of improving working conditions, absorbing shock and shock absorption, and improving working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

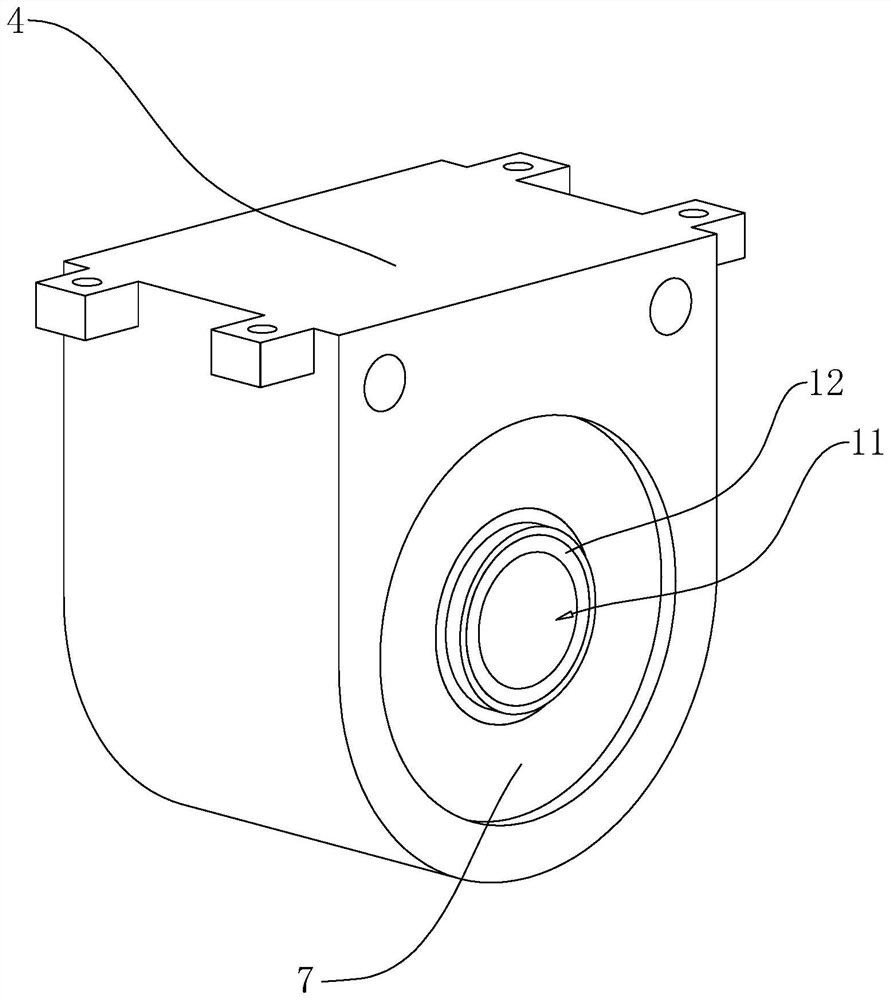

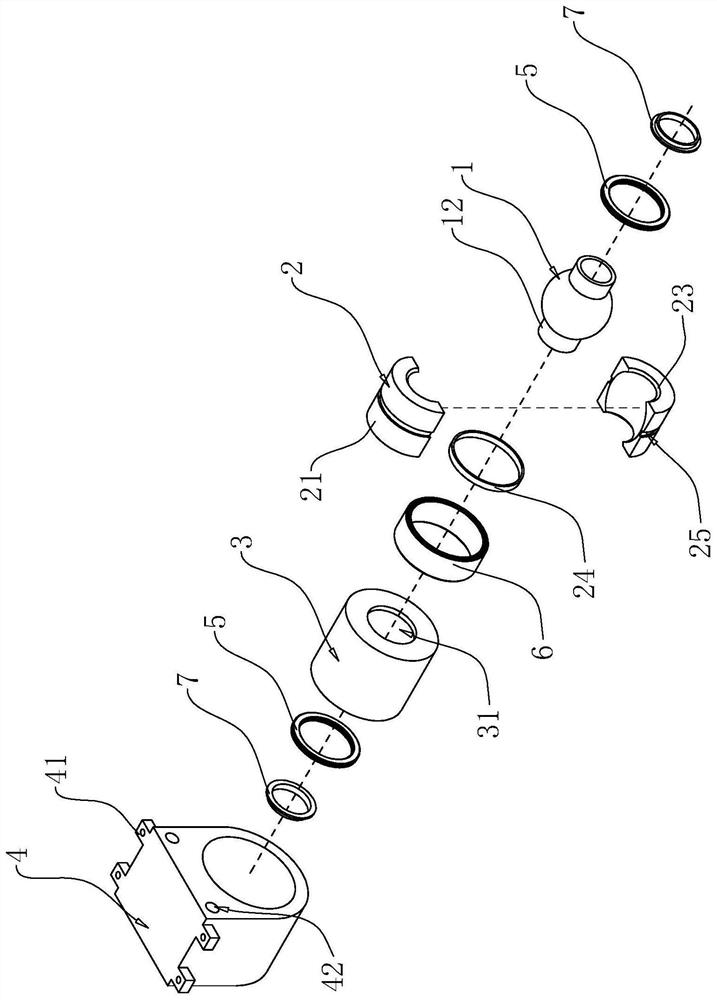

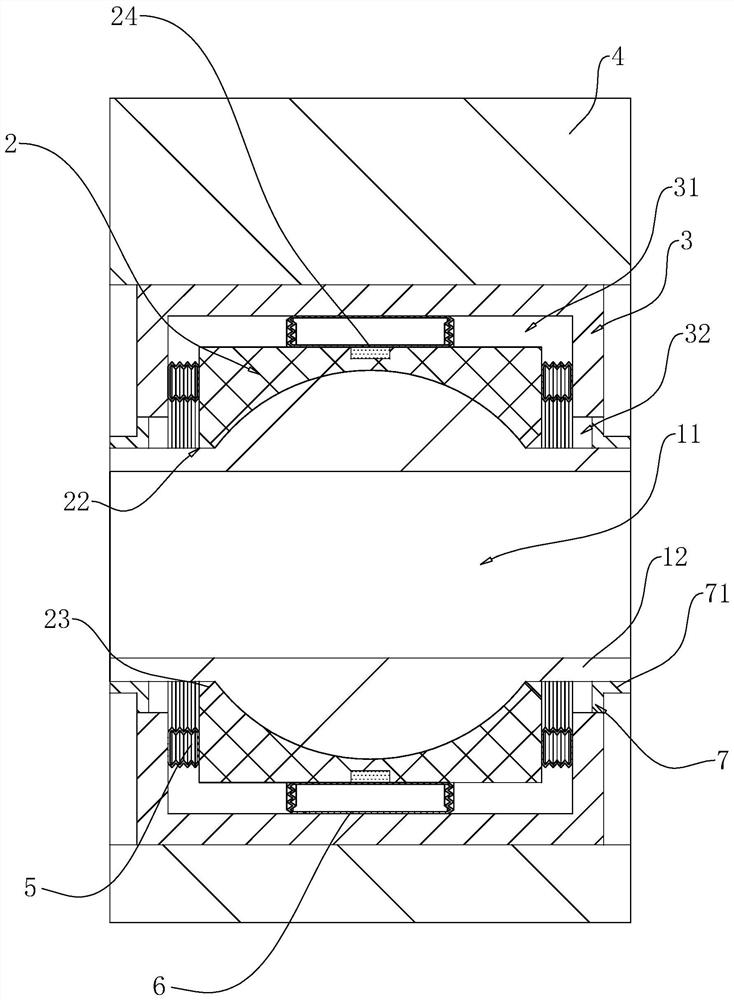

[0046] refer to figure 1 with figure 2 , the embodiment of the present application discloses an intermediate support bearing assembly, which is used in cooperation with an automobile transmission shaft. The intermediate support bearing assembly includes a polyurethane ball head 1, a ball head shell 2, a bearing seat 3 and a support seat 4.

[0047] refer to figure 2 with image 3, The polyurethane ball head 1 has a shaft hole 11 and a shaft sleeve 12 . Wherein, the shaft-through hole 11 passes through the polyurethane ball head 1 in a radial direction, and has openings on opposite sides of the polyurethane ball head 1 . The shaft sleeve 12 is a cylindrical structure with a radial section of a ring, and there are two sets, which are respectively symmetrically arranged at the openings of the shaft passing hole 11 on opposite sides of the polyurethane ball head 1 and extend outward. During use, the power transmission shaft of the automobile is passed through the shaft hole...

Embodiment 2

[0082] An intermediate support bearing assembly disclosed in this embodiment and the polyurethane composite material used for the assembly are basically the same as in Example 1, the difference is that the composition ratio of the polyurethane composite material is different, specifically: polyurethane elastomer 100kg , microcapsule lauryl alcohol 5kg, plant fiber 12kg, polyethylene glycol fatty acid ester 0.5kg, paraffin 1kg, starch 8kg, polytetrafluoroethylene powder 5kg, stearic acid 1kg, molybdenum disulfide 4kg, carbon black 35kg, 0.5kg of plasticizer, 1.5kg of anti-aging agent, 3kg of vulcanizing agent, 1.3kg of vulcanization auxiliary agent and 0.1kg of sulfur.

Embodiment 3

[0084] An intermediate support bearing assembly disclosed in this embodiment and the polyurethane composite material used for the assembly are basically the same as in Example 1, the difference is that the composition ratio of the polyurethane composite material is different, specifically: polyurethane elastomer 100kg , microcapsule lauryl alcohol 8kg, plant fiber 3kg, polyethylene glycol fatty acid ester 2kg, paraffin 5kg, starch 15kg, polytetrafluoroethylene powder 2kg, stearic acid 5kg, molybdenum disulfide 1kg, carbon black 20kg, plasticizer 1.5kg of anti-aging agent, 0.5kg of anti-aging agent, 4kg of vulcanizing agent, 0.8kg of vulcanization auxiliary agent and 0.3kg of sulfur.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com