Workpiece defect measuring device and method based on Rydberg atoms

A technology of measuring device and measuring method, applied in the direction of measuring device, transmittance measurement, optical device, etc., to achieve the effects of simple measurement operation, real-time online feedback, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

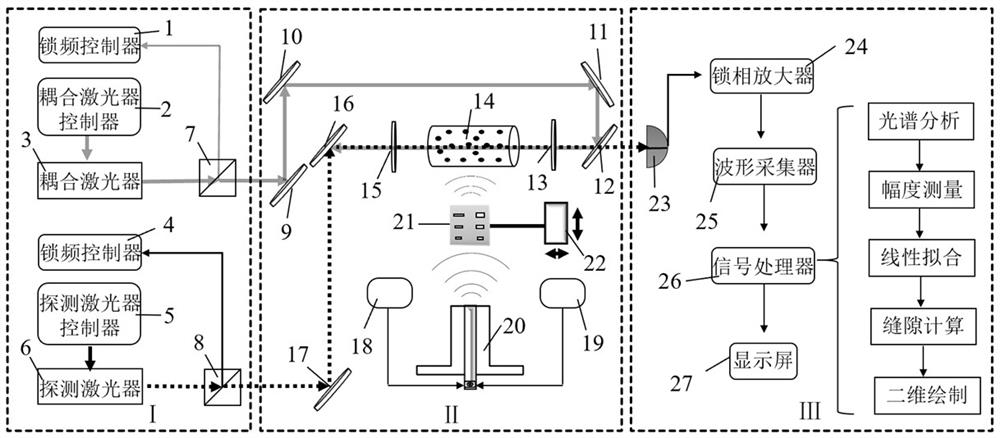

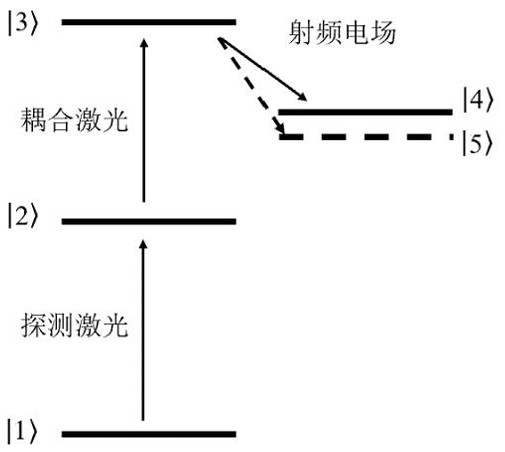

[0035] Such as figure 1 As shown, Embodiment 1 of the present invention provides a workpiece defect measurement device based on Rydberg atoms, including a detection light source, a coupling light source, an alkali metal atom gas cell 14, a first light guide device, a second light guide device, and a second light guide device. A radio frequency signal source 18, a second radio frequency signal source 19, a waveguide 20, a workpiece carrying mechanism 22 to be measured, a photoelectric detector 23 and a data acquisition and processing module; A light-guiding device and a second light-guiding device are oppositely coincident and incident on the alkali metal atom gas chamber 14 for exciting the atoms to the Rydberg state; the first radio-frequency signal source 18 and the second radio-frequency signal source 19 The signal output end is connected with the waveguide 20, and is used to output microwave signals with frequency difference respectively. After the microwave signal passes ...

Embodiment 2

[0059] Embodiment 2 of the present invention provides a measurement method of a workpiece defect measurement device based on Rydberg atoms, comprising the following steps:

[0060] S1. Obtain the relationship between the electric field strength of the transmission signal and the crack width.

[0061] Among them, the specific method to obtain the relationship between the electric field intensity of the transmission signal and the crack width is as follows:

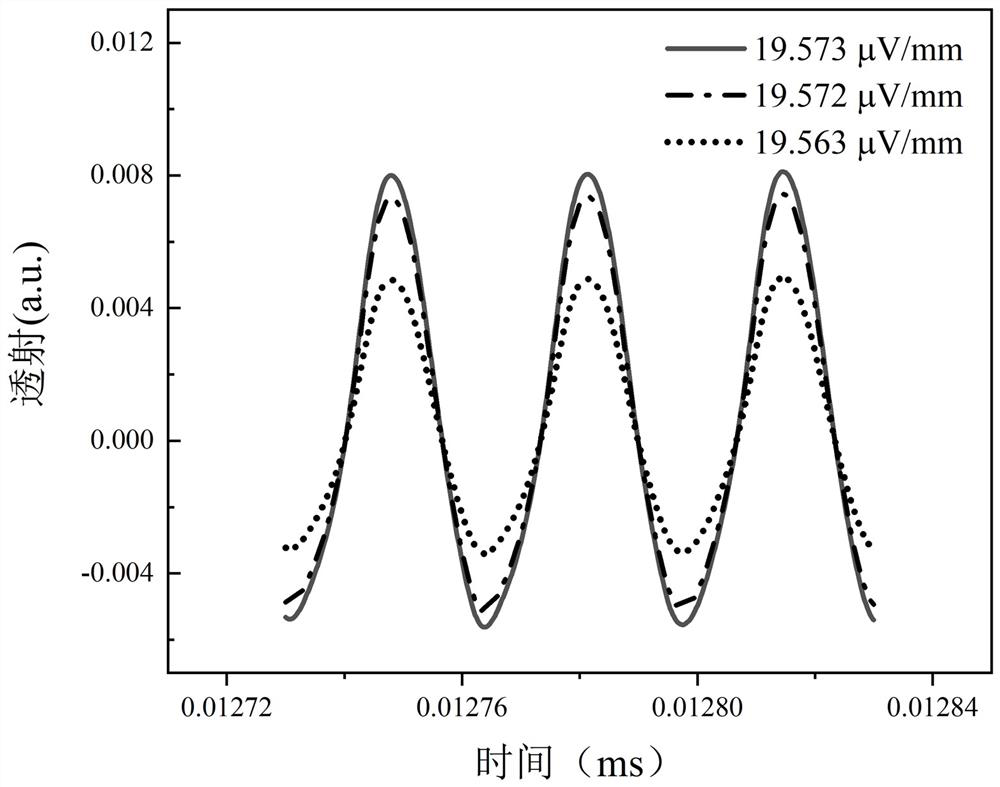

[0062] Set a plurality of calibration samples with known crack widths, set the calibration samples at the waveguide 20, make the microwave signal emitted by the waveguide 20 interact with the Rydberg atoms after passing through each crack of the calibration sample, and collect the probe light through the Rydberg atoms According to the different slit widths and the corresponding electric field strengths of the transmission signals, the final transmission signals are fitted by the least squares method to obtain the relationsh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com