Piezoresistive miniature electric field sensor, preparation method thereof and electric field sensor

An electric field sensor and piezoresistive technology, which is applied in the fields of electromagnetic field characteristics, electrostatic field measurement, and measurement of the property and force of piezoresistive materials, can solve the problem of high power consumption, achieve low power consumption, realize batch manufacturing and System integration, the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The invention also discloses a preparation method of a piezoresistive miniature electric field sensor, comprising:

[0059] Step 1: Write a pattern on the photoresist layer 704 above the device layer 701 on the top of the SOI wafer. The pattern includes: the shape pattern of the vibration film 1, the shape pattern of the support beam 2, the shape pattern of the piezoresistive pickup element 3 and the anchor region 4 shape pattern;

[0060] Wherein, at least one end of the piezoresistive vibration pickup element 3 is connected to the anchor region 4;

[0061] Wherein, the vibrating membrane 1 is connected with the piezoresistive vibration pickup element 3 through the support beam 2;

[0062] Step 2: Etch the device layer 701 on the top of the SOI wafer according to the pattern described in step 1, form the vibration film 1, the support beam 2, the piezoresistive pickup element 3 and the anchor region 4, and remove the photoresist layer 704;

[0063] Step 3: Etching a w...

Embodiment 1

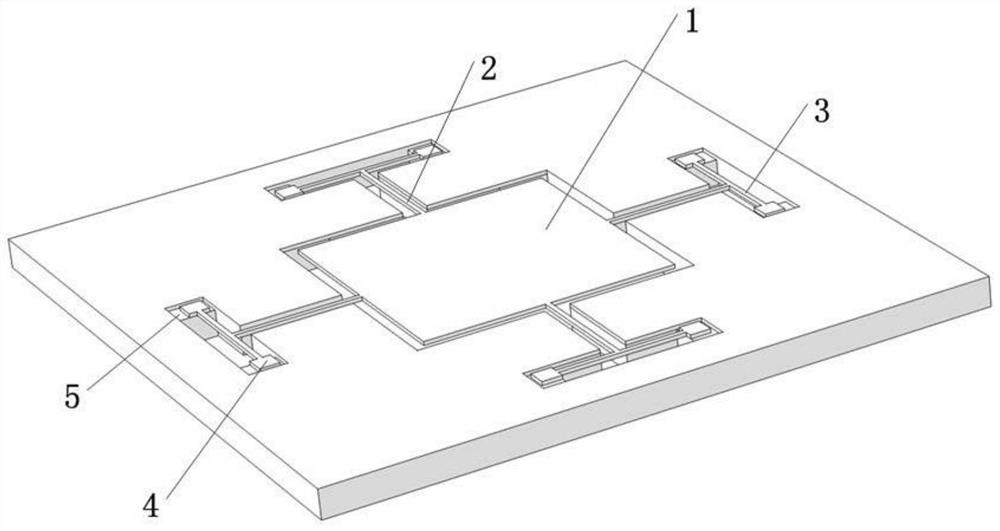

[0081] Such as figure 1 As shown, piezoresistive miniature electric field sensors include:

[0082] The vibration film 1 is connected to the piezoresistive pickup element 3 through the support beam 2 , and the piezoresistive pickup element 3 is fixed on the top of the substrate 5 through the anchor region 4 .

[0083] The vibrating membrane 1 can be a square membrane structure, and the square membrane structure has no through holes.

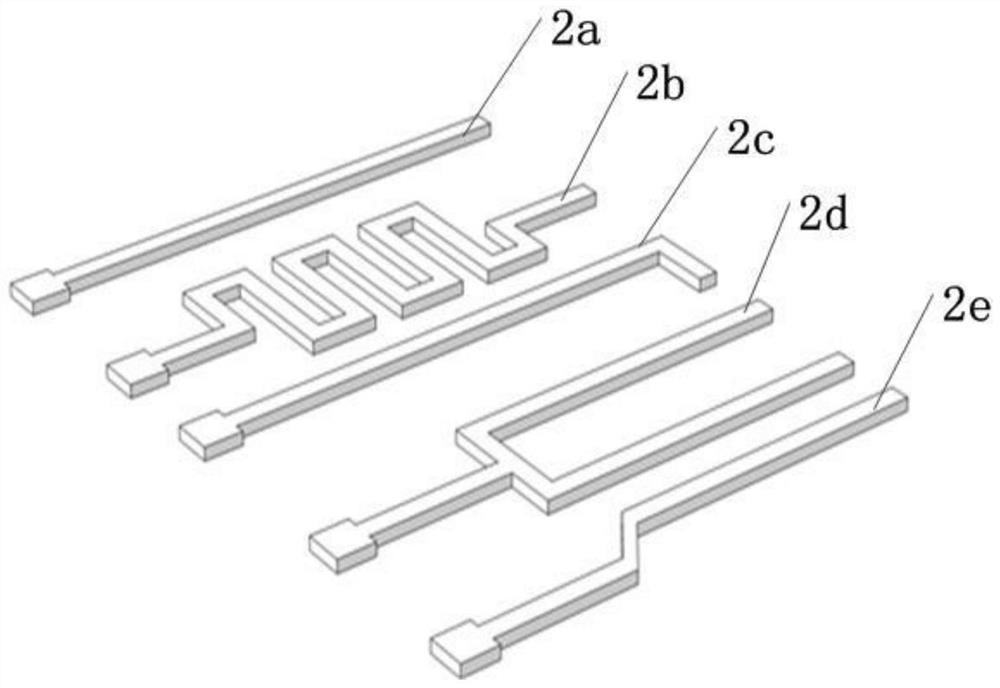

[0084] Such as figure 2 As shown, the shape of the support beam 2 can be a straight beam 2a, a serpentine beam 2b, an L-shaped beam 2c, a U-shaped beam 2d or an irregular beam 2e, etc. The support beam 2 in this embodiment adopts a straight beam 2a, One end of the support beam 2 is set at the midpoint of the piezoresistive pickup element 3 , and the other end is set at the midpoint of the side of the vibrating membrane 1 .

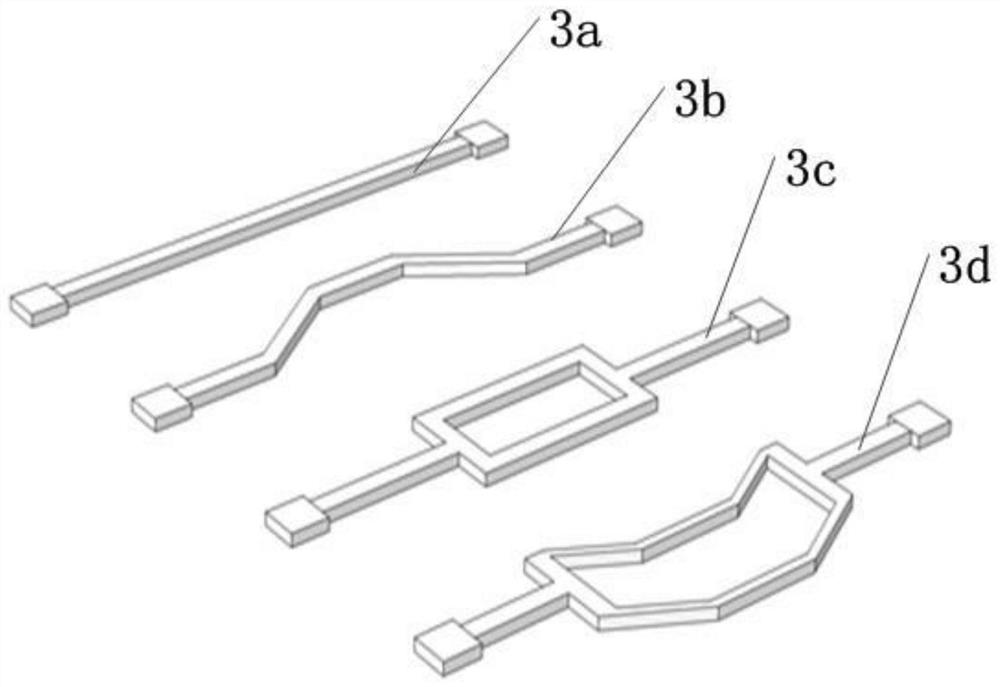

[0085] The piezoresistive vibration pickup element 3 in this embodiment adopts a straight beam structure 3 a, and both ...

Embodiment 2

[0087] Such as Figure 4 As shown, the difference between the piezoresistive miniature electric field sensor in this embodiment and Embodiment 1 is that the piezoresistive vibration pickup element 3 adopts a tuning fork beam structure 3c.

[0088] In one embodiment of the present invention, a preparation method of a piezoresistive miniature electric field sensor is also disclosed;

[0089] Such as Figure 5 shown, including the following steps:

[0090] S1: Spin-coat a photoresist layer 704 on the device layer 701 of the SOI wafer as a mask material, and use a mask plate to perform photolithography to form a Figure 5 The structural shape shown in Figure A;

[0091] S2: The sensor vibration film 1, the support beam 2, the piezoresistive pickup element 3 and the anchor region 4 are etched on the device layer 701 by using the DRIE process, and the photoresist layer 704 is removed to form a Figure 5 The structural shape shown in Figure B;

[0092] S3: Etch a window on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com