A kind of sodium ion battery and preparation method thereof

A sodium-ion battery and battery internal resistance technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as slow speed and low energy density, reduce irreversible losses, increase capacity, and accelerate migration speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

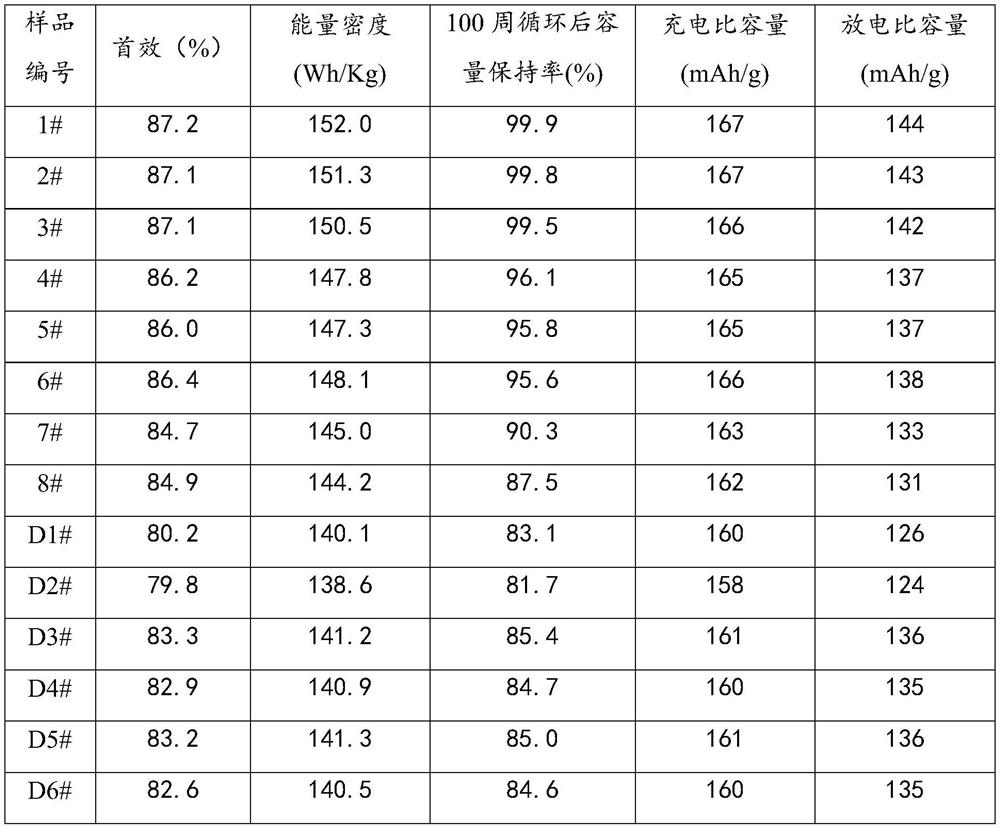

Examples

preparation example Construction

[0067] The preparation method of the sodium ion battery to be formed may further comprise the steps:

[0068] In the preparation of sodium ion batteries, the positive electrode material is sodium ion transition metal oxide, and the negative electrode material is biomass hard carbon. The sodium salt in the sodium salt electrolyte is sodium hexafluorophosphate, and the solvent is EC / DEC / PC. Dry membrane.

Embodiment 1

[0070] (1) Prepare a sodium ion battery to be formed, wherein the negative pole of the sodium ion battery is hard carbon, the positive pole is a sodium ion oxide, the electrolyte is a sodium salt electrolyte, and the sodium salt in the sodium salt electrolyte is sodium hexafluorophosphate, and the solvent It is dimethyl carbonate, the cation is nickel ion, and the anion is phosphate ion;

[0071] (2) Place the sodium-ion battery to be formed in step (1) at 25°C for 15 hours;

[0072] (3) The first time into:

[0073] S1: At a temperature of 35°C and a pressure of -0.09Mpa, charge the sodium-ion battery in step (2) for 30 minutes at a rate of 0.01C. After charging, lower the battery temperature to 25°C and let it stand for 10 minutes;

[0074] S2: At a temperature of 45°C and a pressure of -0.07Mpa, charge the sodium-ion battery prepared in S1 at a rate of 0.02C for 60 minutes. After charging, lower the battery temperature to 25°C and let it stand for 5 minutes;

[0075] S3: ...

Embodiment 2

[0088] (1) Prepare a sodium ion battery to be formed, wherein the negative pole of the sodium ion battery is hard carbon, the positive pole is a sodium ion oxide, the electrolyte is a sodium salt electrolyte, and the sodium salt in the sodium salt electrolyte is sodium tetrafluoroborate, and the solvent It is ethyl acetate, the cation is copper ion, and the anion is oxygen ion;

[0089] (2) Place the sodium ion battery to be formed prepared in step (1) at 25° C. for 10 h;

[0090] (3) The first time into:

[0091] S1: At a temperature of 25°C and a pressure of -0.09Mpa, charge the sodium-ion battery in step (2) for 40 minutes at a rate of 0.02C. After charging, lower the battery temperature to 25°C and let it stand for 8 minutes;

[0092] S2: At a temperature of 49°C and a pressure of -0.07Mpa, charge the sodium-ion battery prepared in S1 at a rate of 0.05C for 60 minutes. After charging, lower the battery temperature to 25°C and let it stand for 8 minutes;

[0093] S3: At a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com