Circular mold for biomass particle forming machine and preparation method of circular mold

A technology of biomass granules and molding machines, which is applied in the direction of biofuel, mold extrusion granulation, waste fuel, etc. It can solve the problems of reduced service life of the ring die, affecting the metal characteristics of the ring die, reducing the strength of the ring die, etc., to achieve improved Effect of service life, guaranteed strength, and reduced wear rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a ring die for a biomass particle molding machine, specifically comprising the following steps,

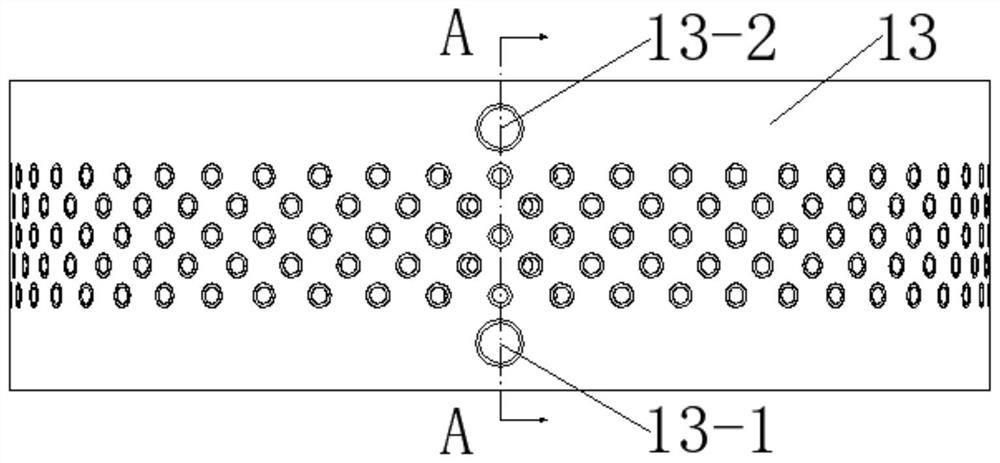

[0045] Step S1: Carry out clockwise milling on the middle mold base 11 to correct the spiral groove 11-1;

[0046] Step S2: Carry out counterclockwise milling of the anti-helical groove 11-2 on the middle mold base 11, so that the positive helical groove 11-1 and the anti-helical groove 11-2 intersect to form a cooling water network;

[0047] Step S3: Drill out the mold hole 11-3 at the middle position of the grid where the forward spiral groove 11-1 and the reverse spiral groove 11-2 intersect to form a cooling water network.

Embodiment 1

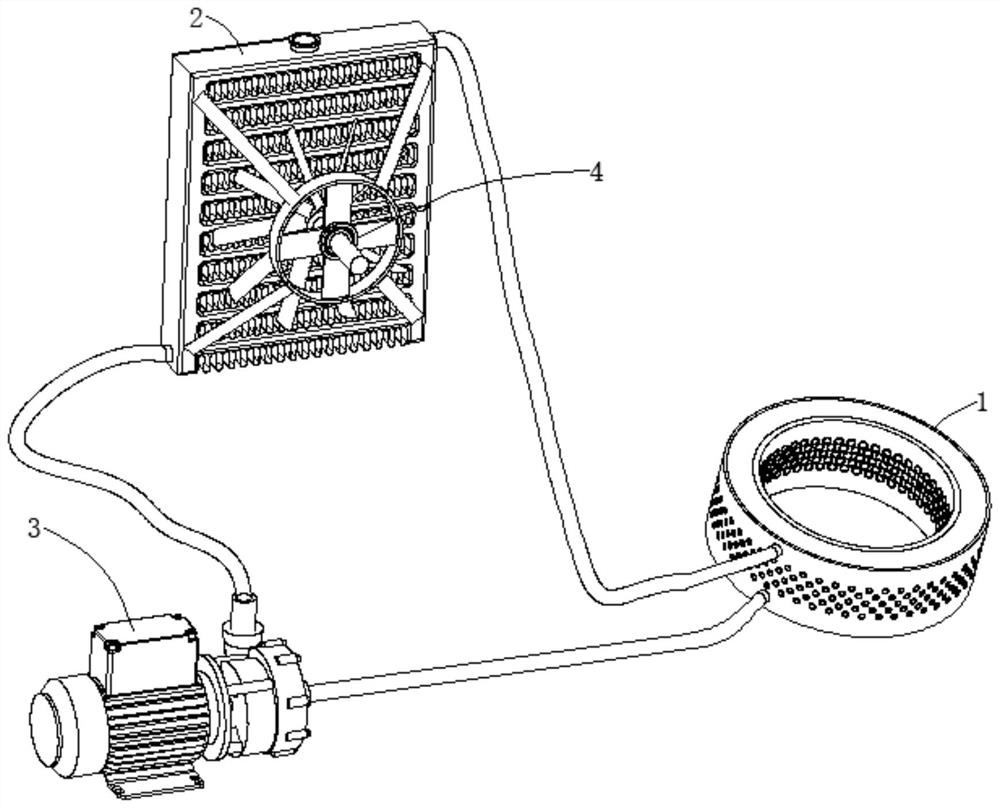

[0050] The biomass particle molding machine uses a ring die, and after the water pump 3 is opened, the cooling water in the water tank 2 is pumped into the annular cavity two 12-1 in the lower mold base 12 through the water inlet hole 13-1, and then the cooling water enters the The positive spiral groove 11-1 and the reverse spiral groove 11-2 intersect to form a cooling water network until it enters the annular cavity 10-1 in the upper mold base 10 to take away the heat in the ring mold assembly 1, and then passes through The pipeline returns to the water tank 2 and is cooled by the cooling fan 4, so that the temperature of the ring die assembly 1 is kept within a reasonable range during the long-term continuous operation, ensuring that the metal properties of the ring die assembly 1 are not affected, and ensuring that the ring die assembly 1 is not affected. Increase the strength, reduce the wear speed of the ring die assembly 1, improve the service life of the ring die assem...

Embodiment 2

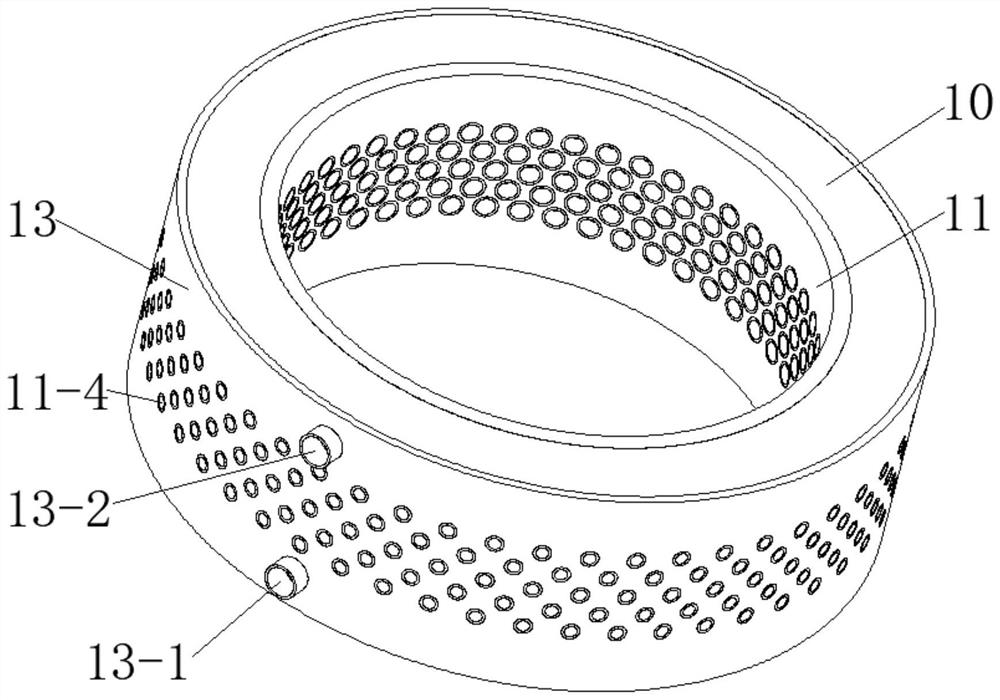

[0054] On the basis of embodiment 1, the lower end of the outer mold sealing cover 13 is provided with a water inlet hole 13-1, and the water inlet hole 13-1 is connected with the water outlet of the water pump 3 through a pipeline, and the outer mold sealing cover 13 The upper end is provided with a water outlet hole 13-2, and the water outlet hole 13-2 is connected to the water inlet of the water tank 2 through a pipeline to realize the circulation of cooling water; the outer wall of the upper mold base 10 is provided with an annular groove 10-2, The lower end surface of the upper mold base 10 is provided with an annular groove two 10-3, the outer wall of the lower mold base 12 is provided with an annular groove three 12-2, and the upper end surface of the lower mold base 12 is provided with an annular groove four 12-3, and the annular groove four 12-3 is arranged on the outer wall of the lower mold base 12. Groove 1 10-2 and annular groove 2 10-3 are sleeved with annular sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com