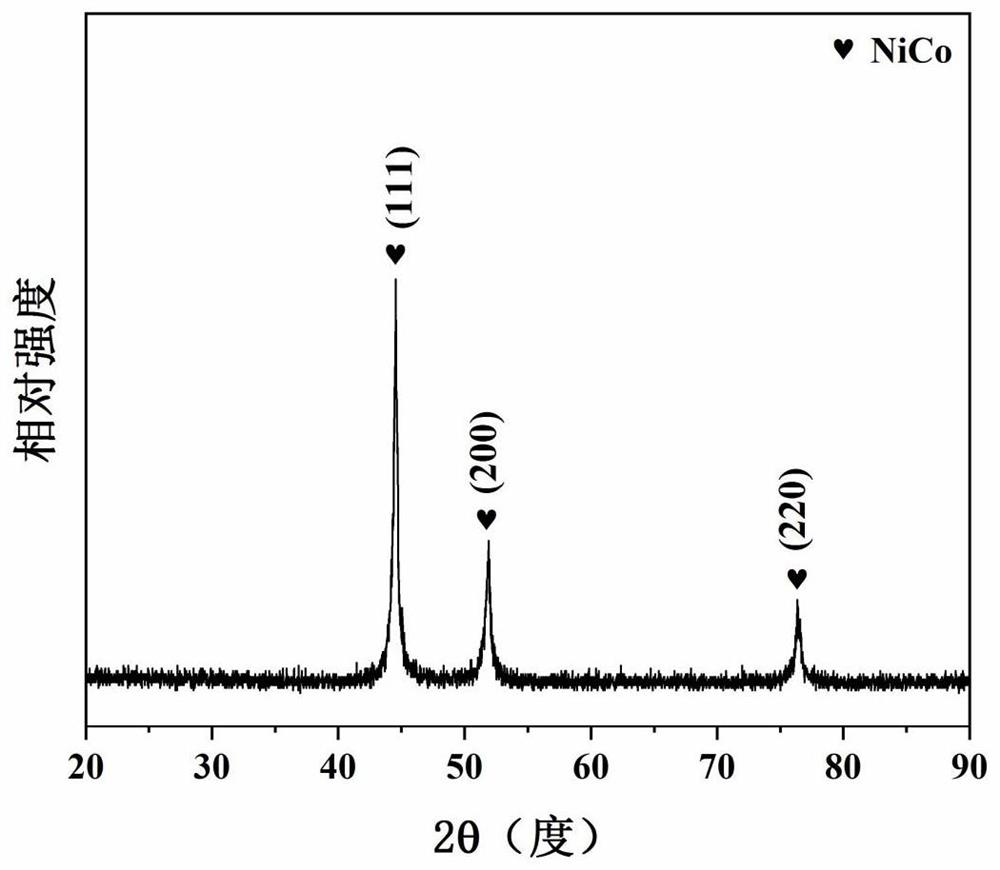

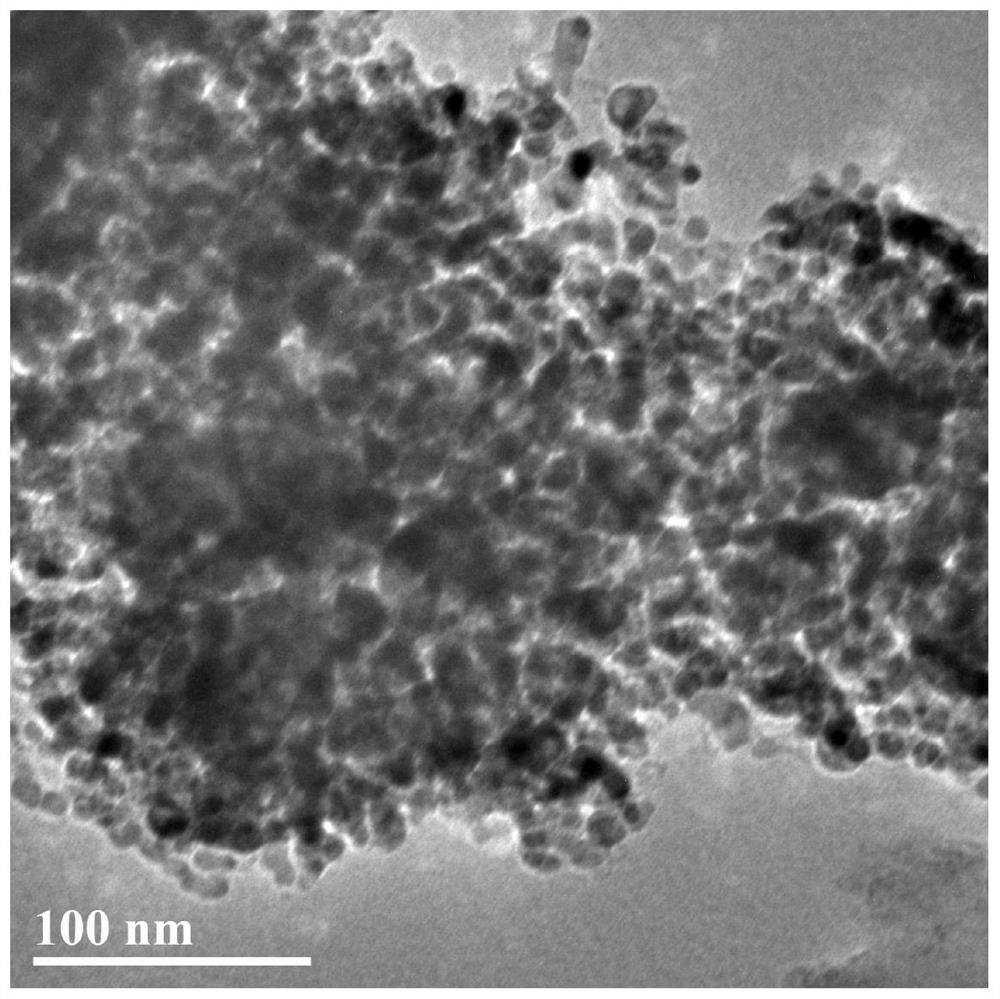

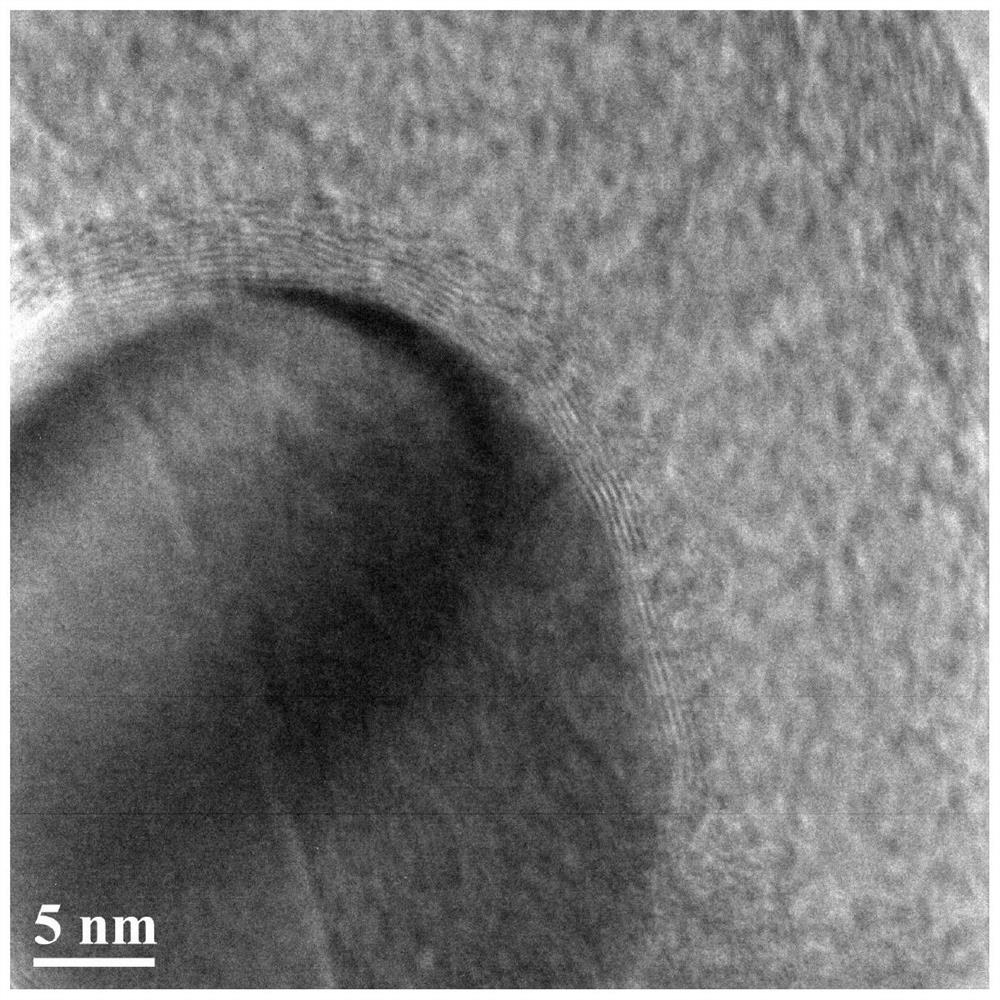

Supported nickel-cobalt bimetallic nano-catalyst and application thereof in catalyzing selective hydrogenation reaction of vanillin

A bimetallic nano-catalysis technology for vanillin, which is applied in metal/metal oxide/metal hydroxide catalysts, catalyst activation/preparation, physical/chemical process catalysts, etc. Poor activity and stability, etc., to achieve the effect of novel and unique structure, prevent dissolution, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) 2.91g of Co(NO 3 ) 2 ·6H 2 0. The 2-methylimidazole of 3.28g is dissolved in the anhydrous methanol of 50ml respectively, the two are mixed, vigorously stirred for 10 minutes, then left to stand for 24 hours, the precipitate obtained is collected, washed three times with ethanol, and finally in Vacuum drying at 80°C overnight to obtain MOF;

[0018] 2) Disperse 0.4g of MOF synthesized in 15ml of ethanol, ultrasonically disperse for 10 minutes, and add 1.6g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 15ml of ethanol, and then added dropwise to the MOF dispersion, then stirred at room temperature for 1 hour, washed by centrifugation with absolute ethanol, dried in a 70-degree oven overnight, and finally heated at 750°C under N 2 Roasting in the atmosphere for 3h;

[0019] 3) Weigh 0.1g of the product of step 2) and place it in the polytetrafluoroethylene liner of the hydrothermal reaction kettle, then add 30ml of ethanol and 0.6g of glucose, and conduct a hydrotherma...

Embodiment 2

[0024] 1) 2.91g of Co(NO 3 ) 2 ·6H 2 0. The 2-methylimidazole of 3.28g is dissolved in the anhydrous methanol of 50ml respectively, the two are mixed, vigorously stirred for 10 minutes, then left to stand for 24 hours, the precipitate obtained is collected, washed three times with ethanol, and finally in Vacuum drying at 80°C overnight to obtain MOF;

[0025] 2) Disperse 0.4g of MOF synthesized in 15ml of ethanol, ultrasonically disperse for 10 minutes, and add 1.0g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 15ml of ethanol, and then added dropwise to the MOF dispersion, then stirred at room temperature for 1 hour, washed by centrifugation with absolute ethanol, dried in a 70-degree oven overnight, and finally heated at 750°C under N 2 Roasting in the atmosphere for 3h;

[0026]3) Weigh 0.2g of the product of step 2) and place it in the polytetrafluoroethylene liner of the hydrothermal reaction kettle, then add 30ml of ethanol and 0.6g of glucose, and conduct a hydrothermal...

Embodiment 3

[0029] 1) 2.91g of Co(NO 3 ) 2 ·6H 2 0. The 2-methylimidazole of 3.28g is dissolved in the anhydrous methanol of 50ml respectively, the two are mixed, vigorously stirred for 10 minutes, then left to stand for 24 hours, the precipitate obtained is collected, washed three times with ethanol, and finally in Vacuum drying at 80°C overnight to obtain MOF;

[0030] 2) Disperse 0.4g of MOF synthesized in 15ml of ethanol, ultrasonically disperse for 10 minutes, and add 2.1g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 15ml of ethanol, and then added dropwise to the MOF dispersion, then stirred at room temperature for 1 hour, washed by centrifugation with absolute ethanol, dried in a 70-degree oven overnight, and finally heated at 750°C under N 2 Roasting in the atmosphere for 3h;

[0031] 3) Weigh 0.2g of the product of step 2) and place it in the polytetrafluoroethylene liner of the hydrothermal reaction kettle, then add 30ml of ethanol and 0.6g of glucose, and conduct a hydrotherma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com