Efficient roller wheel tooth hard alloy surfacing system and surfacing method

A cemented carbide and roll technology, which is applied to the high-efficiency roll tooth cemented carbide surfacing system and the field of surfacing, can solve the problem that it is difficult to obtain a thin and uniform surfacing layer, the high cost of plasma arc surfacing equipment, and arc radiation ozone pollution. and other problems, to achieve the effect of reducing labor cost, simple welding method and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

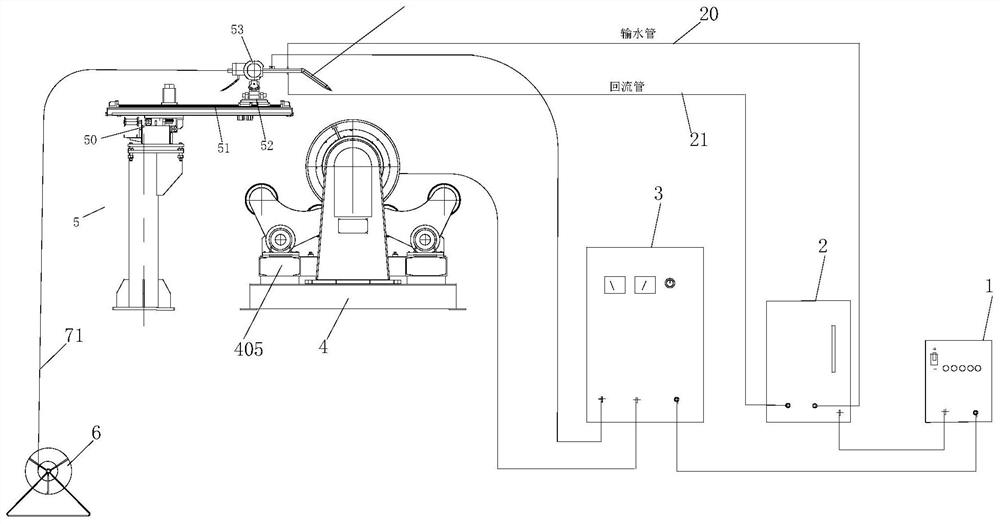

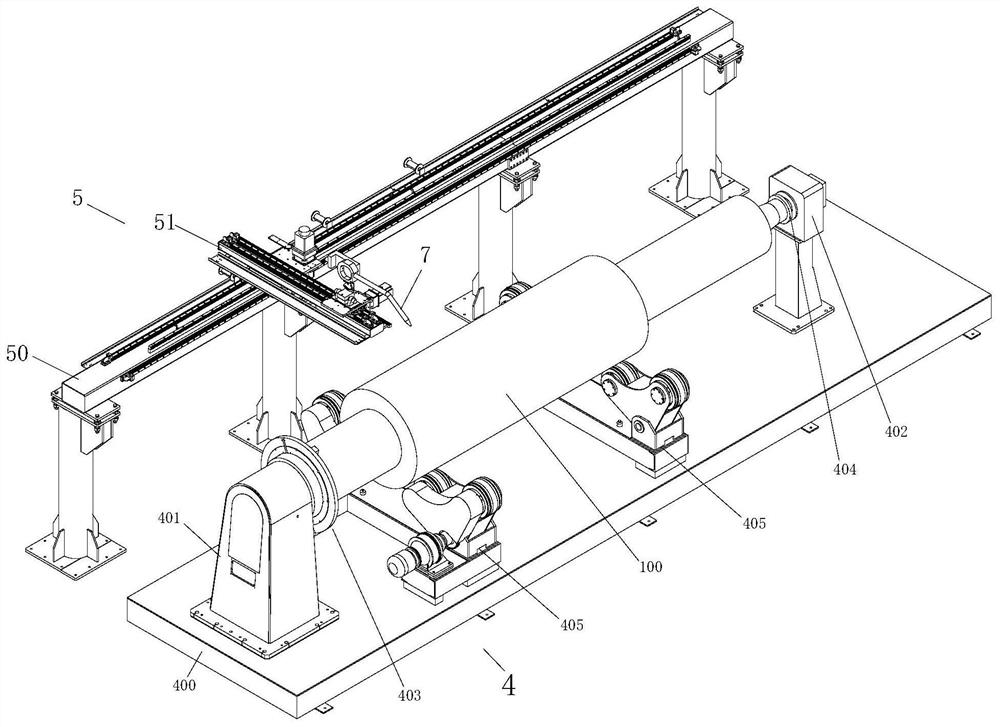

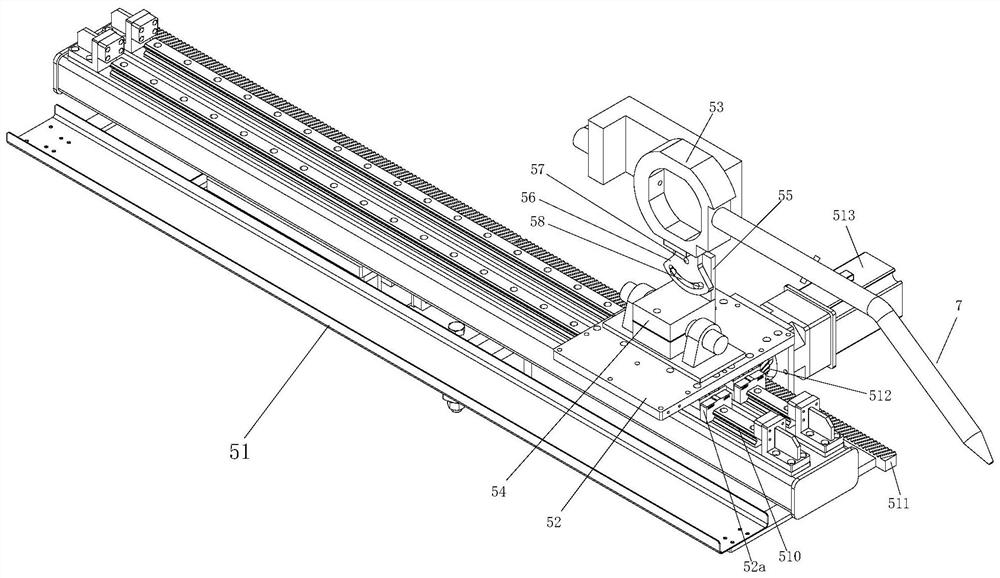

[0029] combine figure 1 and figure 2As shown, a high-efficiency roller tooth cemented carbide overlay welding system according to the present invention includes an electric control box 1, a cold water circulation box 2, a welding machine box 3, a rotary machine tool platform 4, a welding machine mobile platform 5, and a wire feeder 6 and a welding curved gun 7, the welding machine mobile platform 5 includes a horizontal sliding support beam 50, a sliding suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com