Sulfide solid electrolyte, preparation method thereof and all-solid-state battery

A solid electrolyte and sulfide technology, applied in the field of electrolytes, can solve problems such as low ion conductivity and no experimental reports, and achieve the effects of simple operation, improved ion conductivity, and safe and efficient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

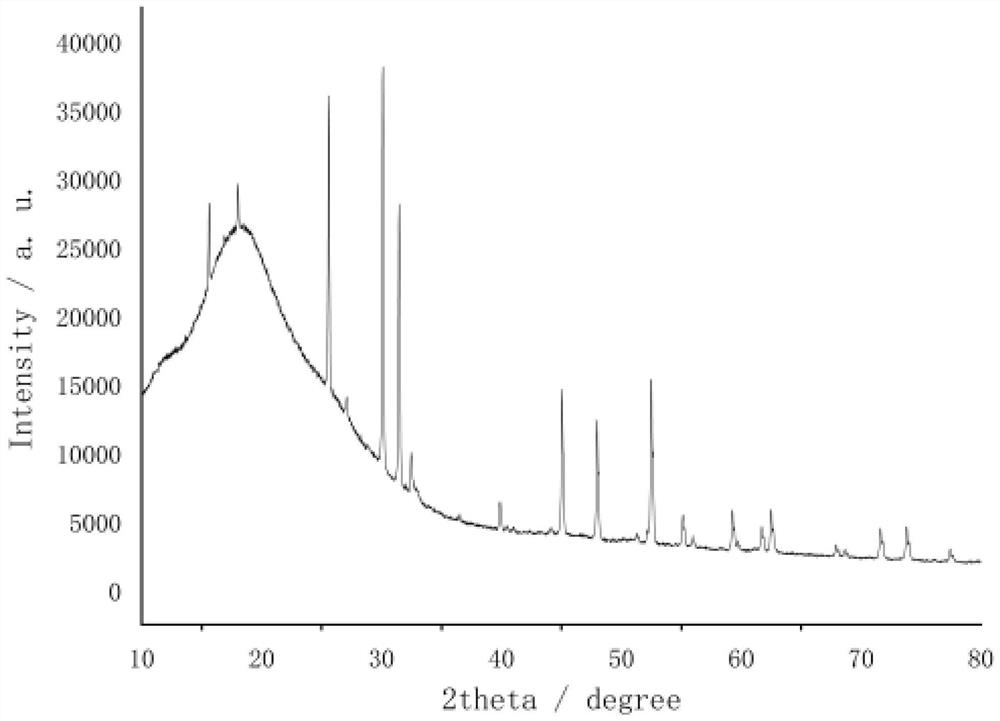

Image

Examples

preparation example Construction

[0028] Based on the same inventive concept, the present application also provides a method for preparing the above-mentioned sulfide solid state electrolyte, comprising the following steps:

[0029] S1. Put Li 2 S, LiCl, LiBH 4 , P 2 S 5 Mix evenly to obtain a mixture;

[0030] S2, the mixture is placed in a ball-milling jar for ball-milling;

[0031] S3, compressing the ball-milled mixture into a tablet and sintering to obtain a sulfide solid electrolyte.

[0032] It should be noted that all the above operation steps are carried out under the argon atmosphere, that is, the mixing, ball milling, tablet pressing and sintering treatments are all carried out under the argon protection. The preparation method of the sulfide solid state electrolyte of the present invention adopts the preparation method combining mechanical ball milling and high-temperature sintering, which is simple in operation and safe and efficient in the preparation process.

[0033] In some embodiments, ...

Embodiment 1

[0043] The embodiments of the present application provide a sulfide solid state electrolyte, the chemical formula of which is Li 6 PS 5 Cl 0.9 (BH 4 ) 0.1 .

[0044] Specifically, the preparation method of the above-mentioned sulfide solid state electrolyte comprises the following steps:

[0045] S1. Weigh Li with a molar ratio of 25:9:1:5 2 S, LiCl, LiBH 4 , P 2 S 5 , and mixed uniformly under an argon atmosphere to obtain a mixture;

[0046] S2. The mixture is ground with an agate mortar for 10 min under an argon atmosphere, and then placed in a ball-milling jar for ball-milling under an argon atmosphere; the ball-milling conditions are: using zirconia balls as the ball-milling medium, and the mass ratio of the mixture to the zirconia balls It is 1:32, the speed of ball milling is 550rpm, and the ball milling time is 15h;

[0047] S3. The ball-milled mixture is ground in an agate mortar for 15 minutes under an argon atmosphere, and then placed in a tablet press und...

Embodiment 2

[0049] The embodiments of the present application provide a sulfide solid state electrolyte, the chemical formula of which is Li 6 PS 5 Cl 0.5 (BH 4 ) 0.5 .

[0050] Specifically, the preparation method of the above-mentioned sulfide solid state electrolyte comprises the following steps:

[0051] S1. Weigh Li in a molar ratio of 5:1:1:1 2 S, LiCl, LiBH 4 , P 2 S 5 , and mixed uniformly under an argon atmosphere to obtain a mixture;

[0052] S2. The mixture is ground with an agate mortar for 10 min under an argon atmosphere, and then placed in a ball-milling jar for ball-milling under an argon atmosphere; the ball-milling conditions are: using zirconia balls as the ball-milling medium, and the mass ratio of the mixture to the zirconia balls It is 1:34, the speed of ball milling is 600rpm, and the ball milling time is 20h;

[0053] S3. The ball-milled mixture is ground in an agate mortar for 15 minutes under an argon atmosphere, and then placed in a tablet press under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com