Long-afterglow luminescent material, preparation method and application thereof, and display device

A long afterglow luminescence and display device technology, applied in the directions of luminescent materials, chemical instruments and methods, can solve the problems of difficulty in obtaining single-phase compounds, reducing product performance, and difficulty in mixing raw materials uniformly, reducing the difficulty of milling and speeding up The effect of improving response speed and luminous brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] An embodiment of the present invention also provides a preparation method of a long-lasting luminescent material, which includes the following steps S10-S20.

[0048] Step S10, according to the general formula Sr 1-y-z al 2-x S x o 4 :yEu 2+ ,zDy 3+ The quantitative relationship provides raw materials: strontium carbonate, aluminum oxide, europium oxide, dysprosium oxide and elemental sulfur, where 0<x<0.5, 0<y<0.1, 0≤z<0.2.

[0049] Understandably, according to the general formula Sr 1-y-z al 2-x S x o 4 :yEu 2+ ,zDy 3+ The metering relationship provides raw materials, which refers to the Sr, Al, S, Eu and Dy in the general formula 3 The molar stoichiometric relationships for strontium carbonate, aluminum oxide, elemental sulfur, europium oxide, and dysprosium oxide are provided accordingly. When z is 0, it means that there is no dysprosium trioxide in the raw material.

[0050] Step S20, after mixing the raw materials provided in step S10, calcining in a ...

Embodiment 1

[0071] 1) Weigh the raw materials aluminum oxide (0.5592 g), strontium carbonate (0.8523 g), europium trioxide (0.0203 g), elemental sulfur (0.0186 g), grind and mix evenly to obtain a mixed material.

[0072] 2) The mixed material in step 1) is placed in a CO atmosphere, and calcined at 1250° C. for 2 hours. Cool naturally to room temperature after calcination, and then grind the product finely to obtain a powdery long-lasting luminescent material with a structure of Sr 0.98 Al 1.9 S 0.1 o 4 :0.02Eu 2+ .

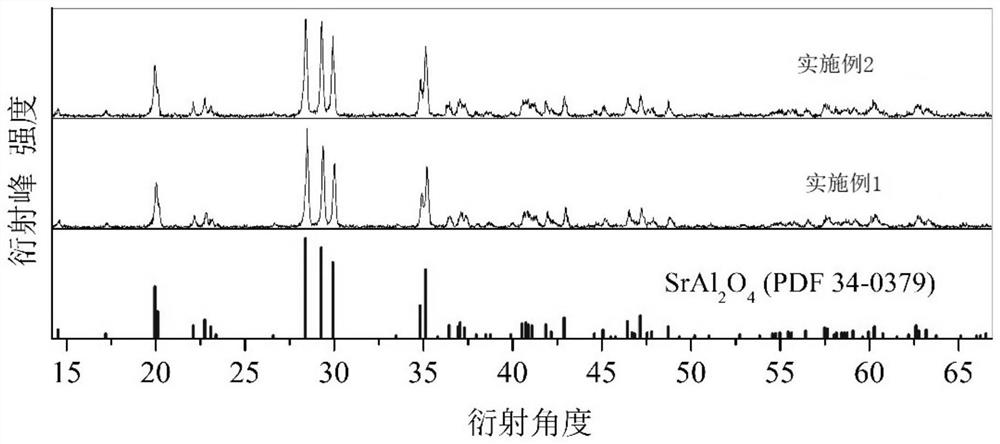

[0073] 3) Carry out X-ray diffraction experiment to the powdery long afterglow luminescent material that embodiment 1 makes, specifically as follows figure 1 shown.

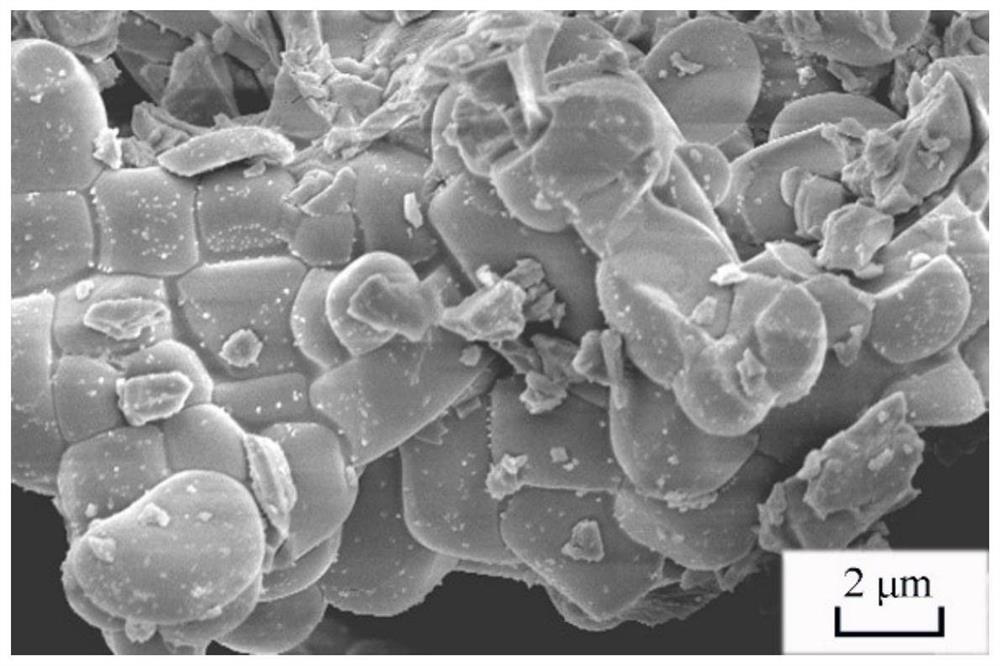

[0074] 4) Scanning electron microscope experiment was carried out on the powdery long afterglow luminescent material prepared in Example 1, and the scanning electron microscope picture is as follows figure 2 shown.

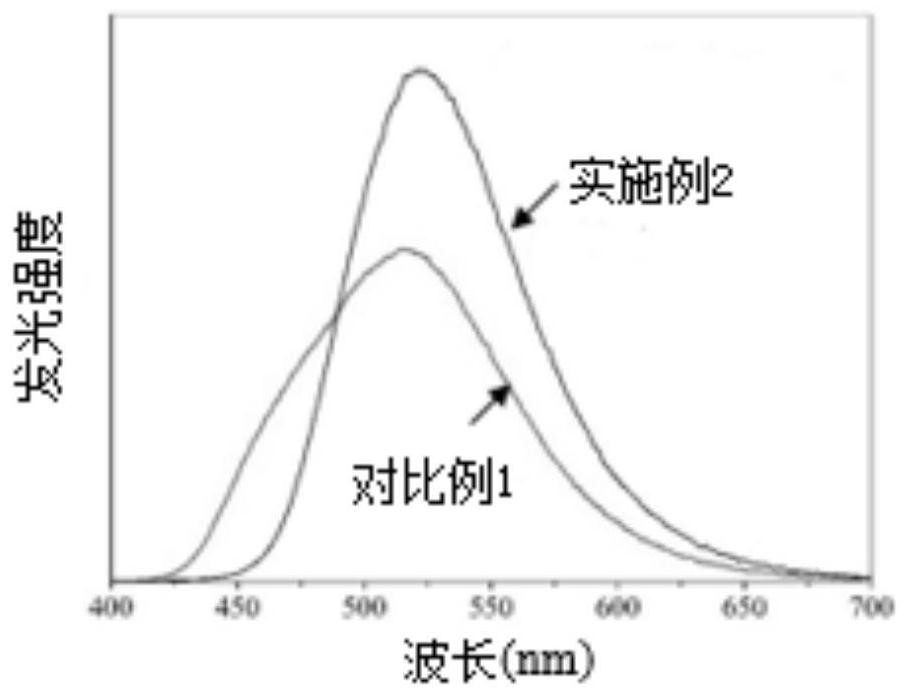

[0075] 5) Excite the powdery long-lasting luminescent material prepared in Example 1 ...

Embodiment 2

[0077] 1) Weigh the raw materials aluminum oxide (0.5298 g), strontium carbonate (0.8523 g), europium oxide (0.0203 g), elemental sulfur (0.0372 g), grind and mix evenly to obtain a mixed material.

[0078] 2) The mixed material obtained in step 1) was calcined at 1250° C. for 2 hours in a CO atmosphere. Cool naturally to room temperature after calcination, and then grind the product finely to obtain a powdery long-lasting luminescent material with a structure of Sr 0.98 Al 1.8 S 0.2 o 4 :0.02Eu 2+ .

[0079] 3) Place the powdery long-lasting luminescent material prepared in Example 2 under the excitation light with a wavelength of 365nm for excitation for 3 minutes, then turn off the excitation light source, and observe the change of the luminous intensity of the long-lasting luminescent material in a dark environment. It is found that: Example 2 The long afterglow of the prepared powder can be observed with naked eyes for 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com